Underground box culvert constructing method closely attached to pile foundation bearing platform

A construction method and a foundation cap technology, applied in excavation, construction, infrastructure engineering, etc., can solve problems such as difficulties in implementing underground box culverts, occupying underground space, and widening caps, so as to meet the requirements for normal operation and construction. Simple steps, significant technical and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

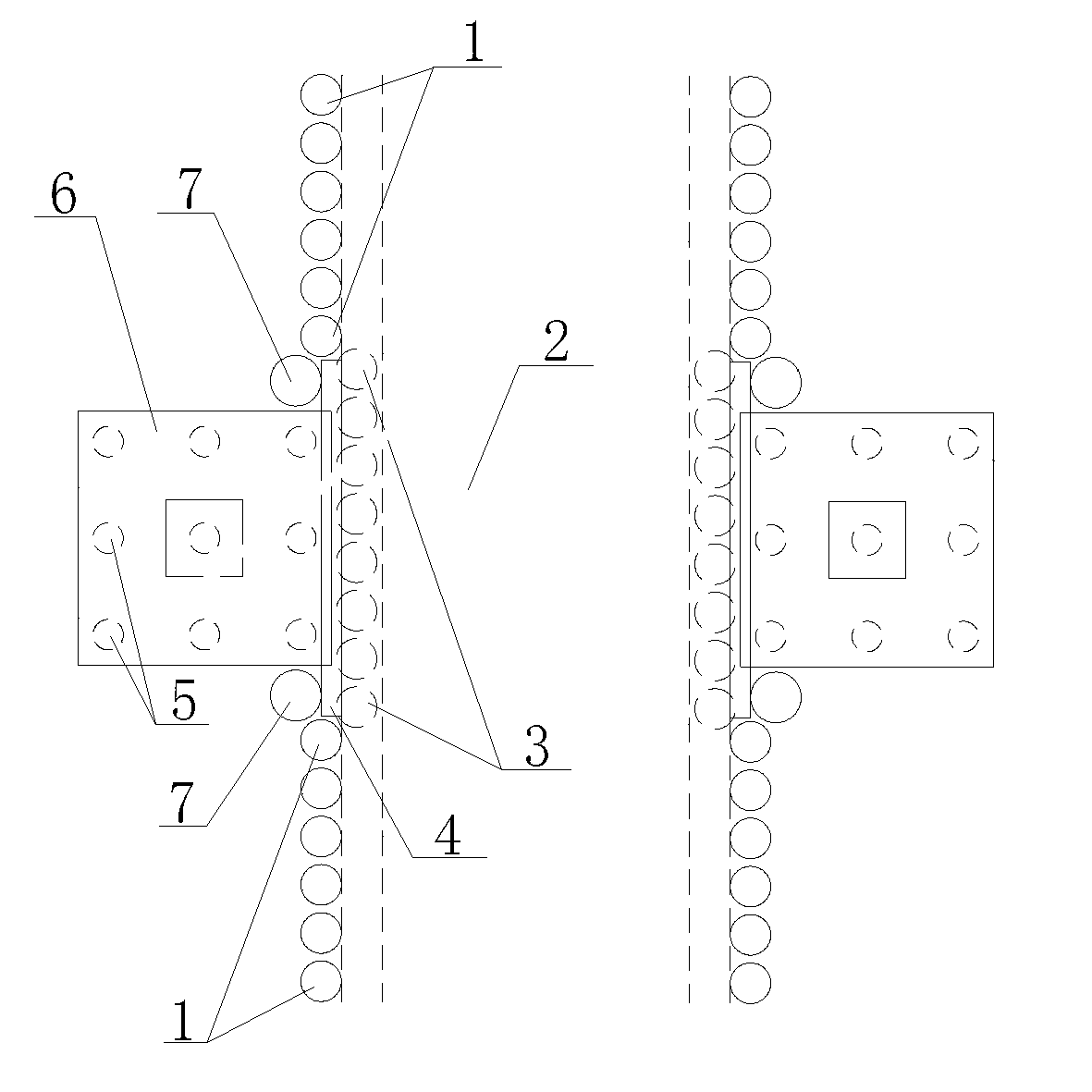

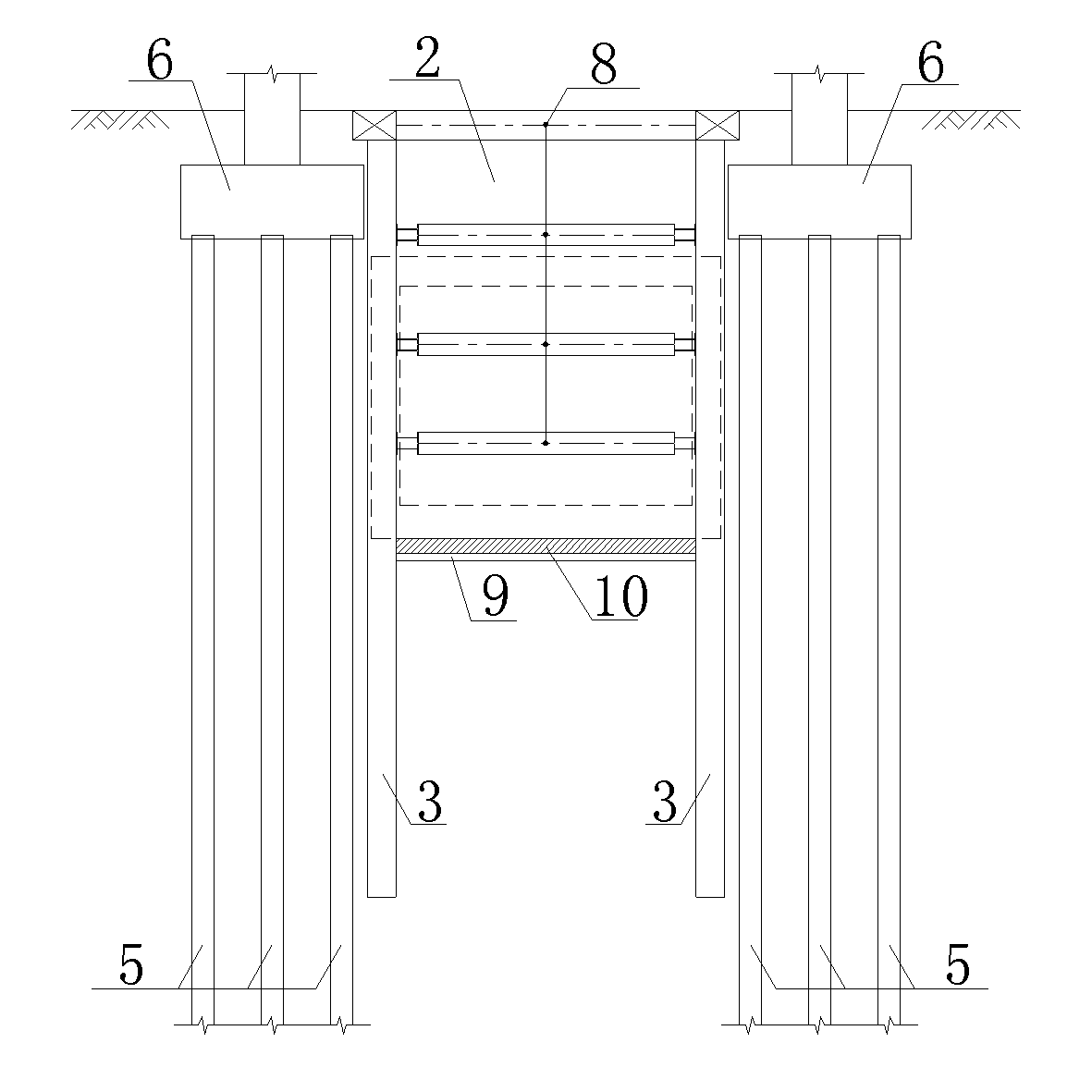

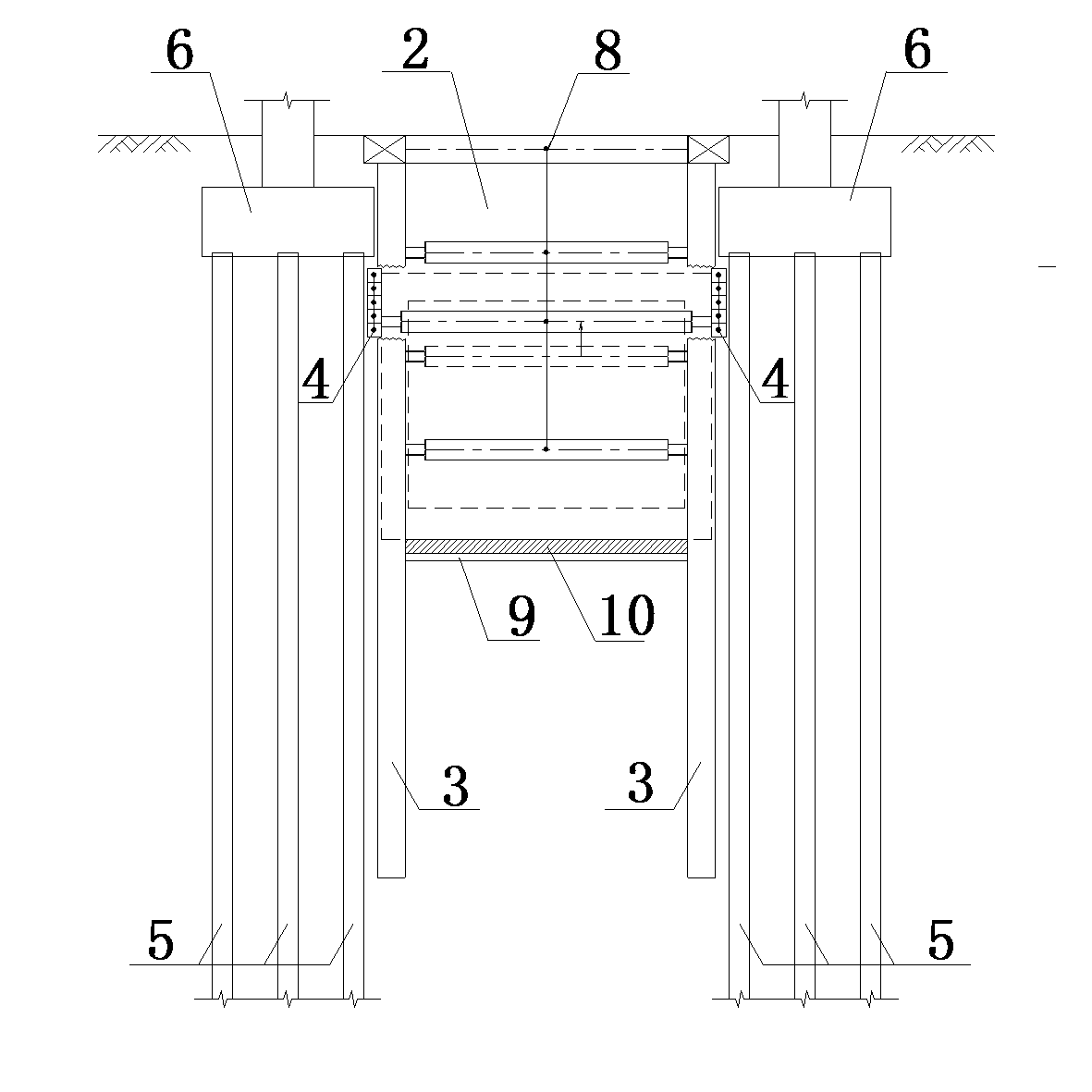

[0024] Example: such as Figure 1-9 As shown, this embodiment specifically relates to a method of constructing an underground box culvert close to the pile cap. The MRT passage to be built in an airport is an underground box culvert structure. The existing overhead airport corridors intersect vertically, and the width of the underground box culvert 11 is equal to the distance between the two existing caps 6. Therefore, the underground box culvert 11 of the MRT passage needs to be close to the existing pile foundation 5 and the bearing platform. The construction of platform 6 is difficult due to the narrow construction space. The following are the specific construction steps of the underground box culvert construction method close to the pile cap:

[0025] A. If figure 1 , 2 , 8, and 10, there is a narrow space between the existing pile foundations 5 on both sides. Firstly, the vertical support structure 7 is driven into the construction close to the two sides of the cap 6, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com