Radial locking type over-load protection shaft

An overload protection and shaft wall technology, which is applied in the field of shaft transmission, can solve problems such as poor reliability of the anti-overload structure, overload fracture of the transmission shaft, damage of transmission parts, etc., and achieve the effect of improving smoothness of shifting, reducing loss and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

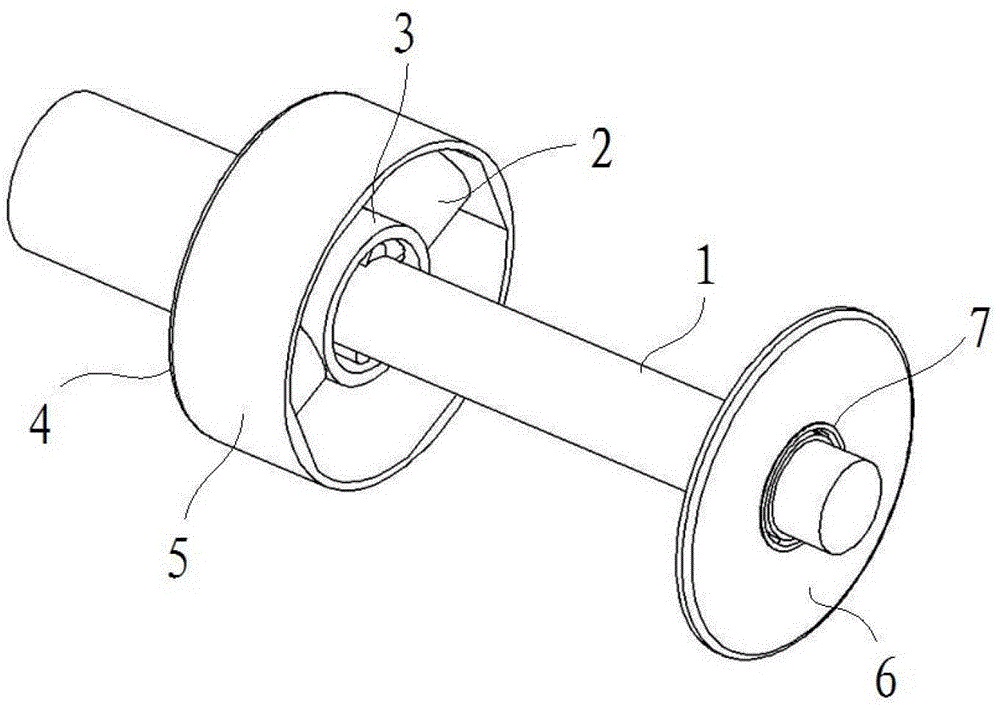

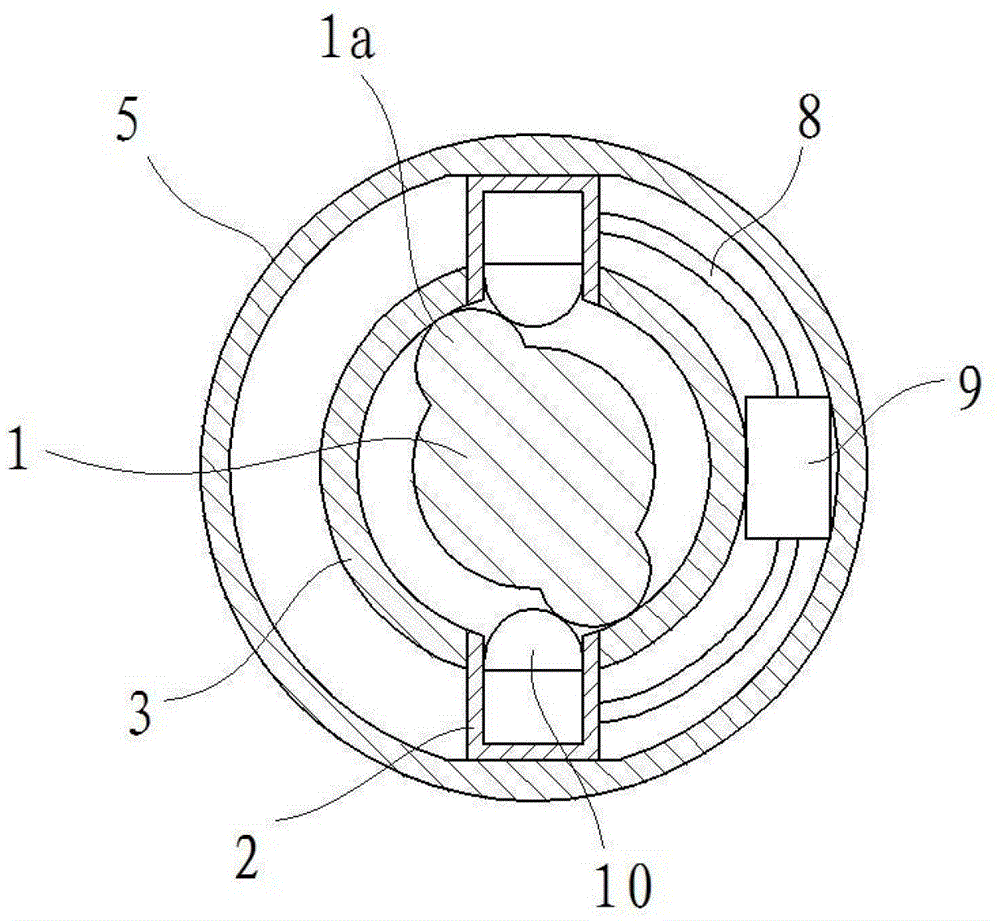

[0025] like figure 1 In the shown embodiment 1, a radial locking overload protection shaft includes a transmission shaft and a support body. The transmission shaft is composed of a first shaft 1 and a second shaft 3, wherein the second shaft is a hollow structure, and the first The shaft is located inside the second shaft, and the two shafts are concentric. A pair of hydraulic cylinders 2 are arranged on the second shaft, and the two hydraulic cylinders are symmetrically arranged on the second shaft. The support body includes a left mounting base 4, a right mounting base 6 and a connecting frame body 5, the left mounting base and the right mounting base are connected through the connecting frame body 5, wherein the left mounting base is fixedly connected to the second shaft, and the center of the right mounting base is provided with The through hole is connected with the first shaft through the rolling bearing 7.

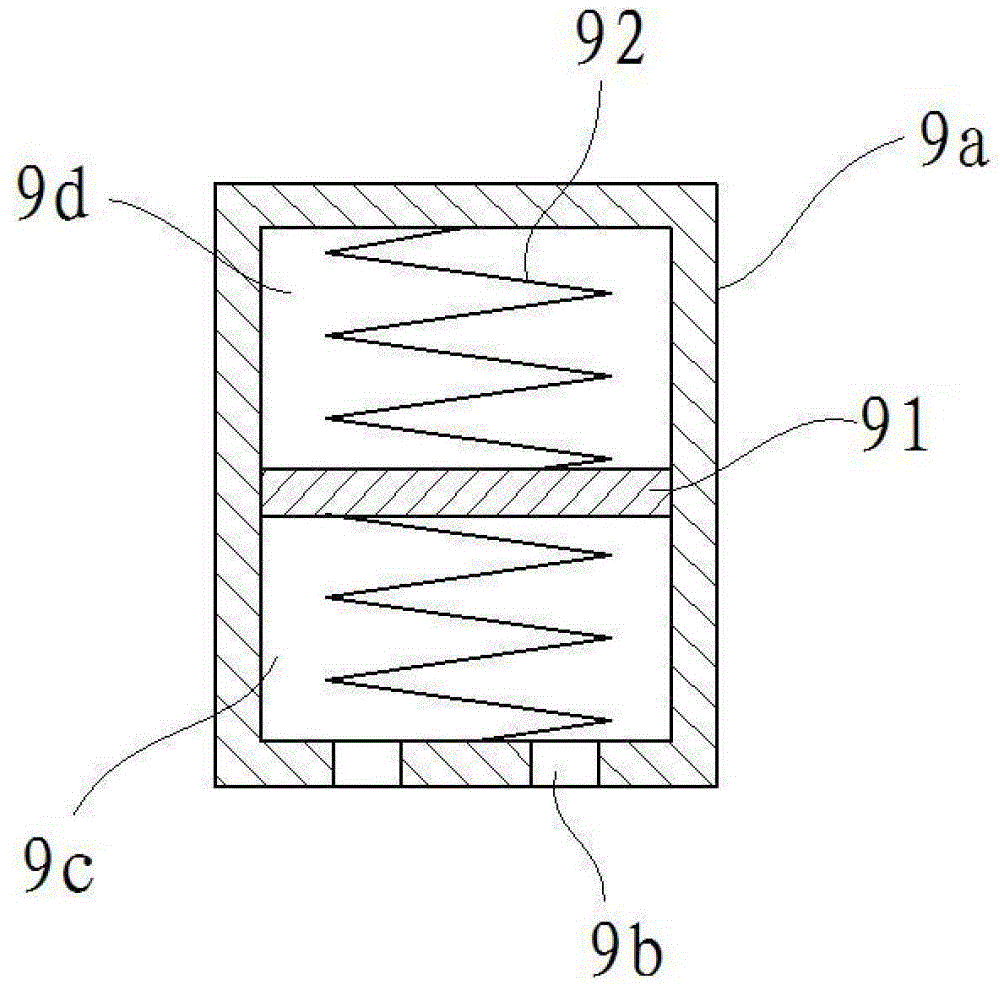

[0026] like figure 2 As shown, the hydraulic cylinder runs...

Embodiment 2

[0030] like Figure 4 In said embodiment 2, a radial locking type overload protection shaft includes a transmission shaft and a support body, the transmission shaft includes a first shaft 1 and a second shaft 3, wherein the second shaft is a hollow structure, and the first shaft Located inside the second axis, and the two axes are concentric. Two pairs of hydraulic cylinders 2 are arranged on the second shaft, the central axes of the four hydraulic cylinders are located on the same cross section of the second shaft, and the included angle between adjacent hydraulic cylinders is 90 degrees. The support body includes a left mounting seat, a right mounting seat and a connecting frame body 5, the left mounting seat and the right mounting seat are connected through the connecting frame body, wherein the left mounting seat is fixedly connected to the second shaft, and the center of the right mounting seat is provided with a through hole. It is connected with the first shaft through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com