Cantilever fan

A cantilever and fan technology, applied in the field of cantilever fans, can solve the problems of performance loss, change in energy conversion properties, and increase in the high cost of laminated piezoelectric actuators.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] To meet industry needs and overcome the limitations of previous work, the present application discloses a cantilever fan with a novel means of blade actuation that overcomes the limitations of piezoelectric stack actuators, thereby providing a high-performance and cost-effective fan technology to Used in thermal management and other air moving applications. To further address these needs and overcome the limitations of previous work, novel actuation means enable the use of practical and reliable actuators to power cantilever fans; address fan lifetime issues; enable high flow in small fan form factors speed; enables near-sinusoidal blade motion with low noise due to high resonance quality factor ("Q") by operating at low frequencies; provides low vibration and reduces size / shape of cantilever fans factor to make it practical for electronics cooling (practical space-constrained high-power products).

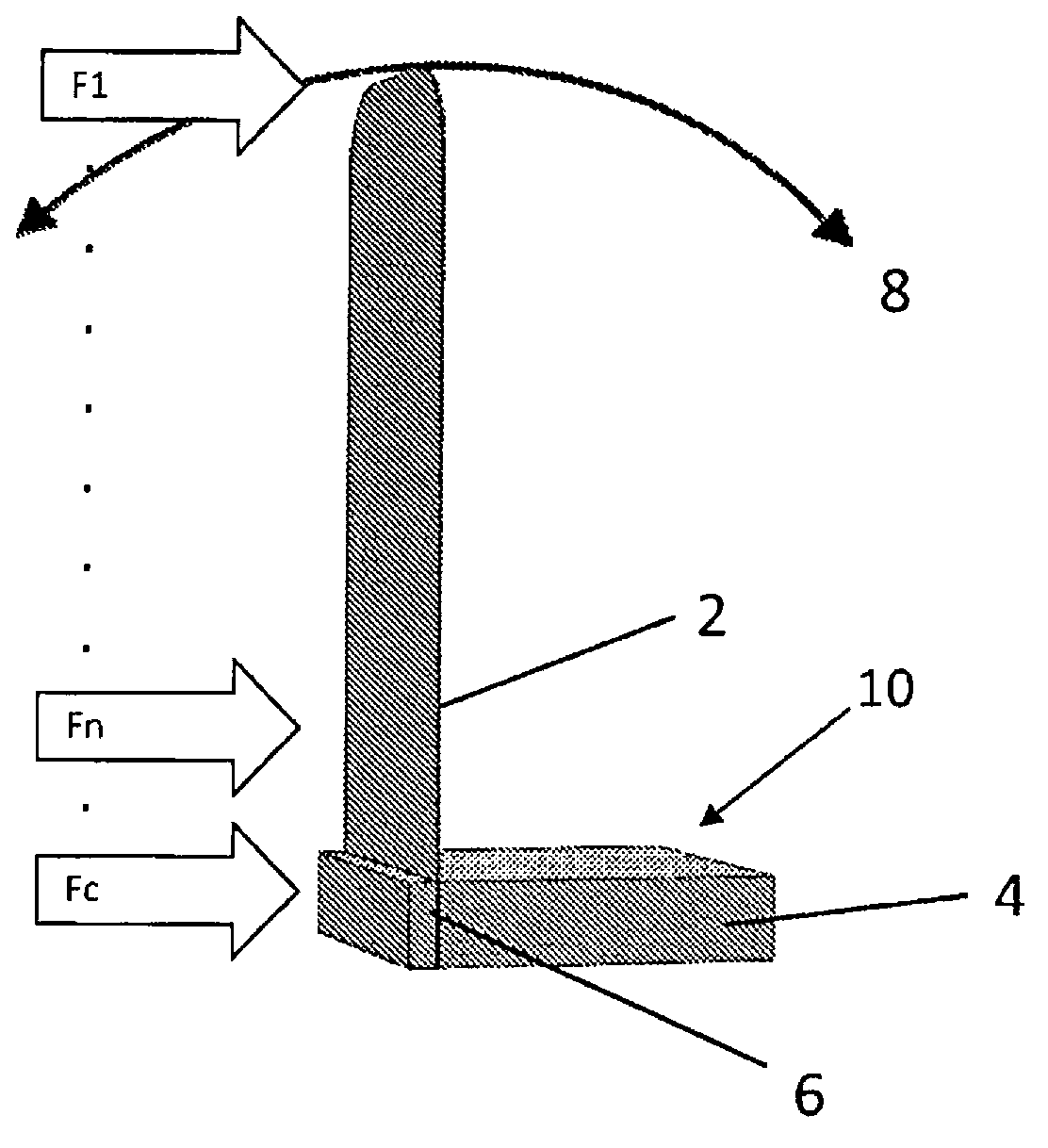

[0035] figure 1 A schematic representation of the range of positions...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com