Coaxial and double-beam shared supporting structure without machine room

A support structure, machine room-less technology, used in elevators, transportation and packaging, etc., can solve problems such as the inability to meet the requirements of the contact area, and achieve the effect of increasing the erection contact area, increasing the stability, and meeting the requirements of the contact area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The structure of the present invention will be further described below in conjunction with the accompanying drawings.

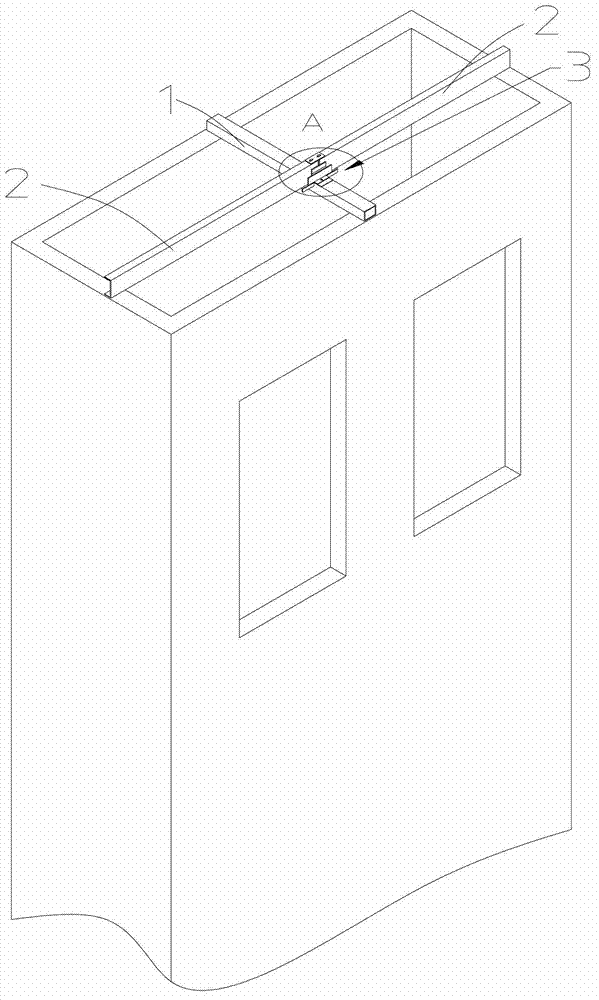

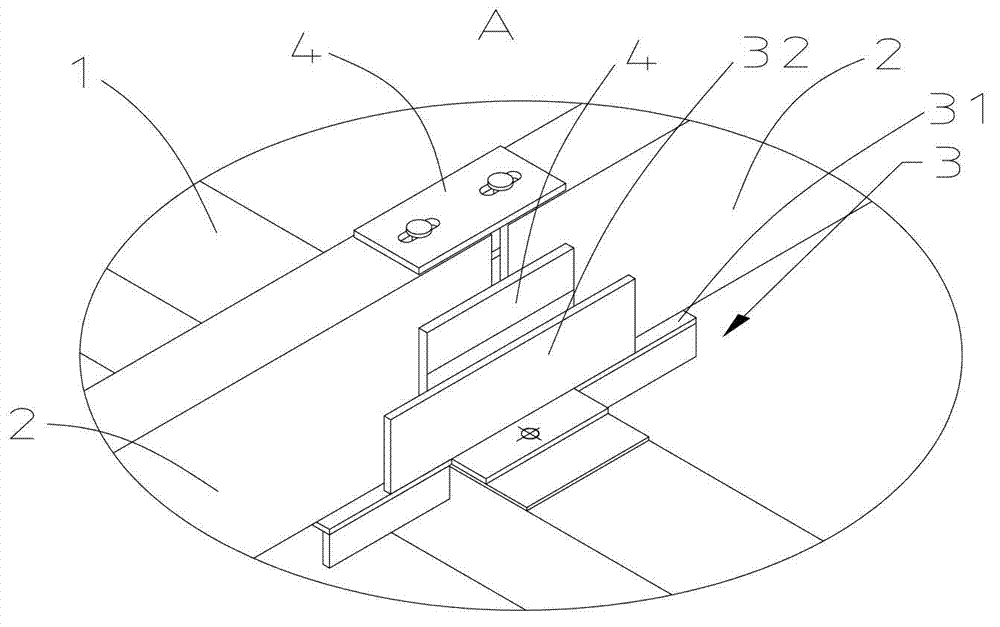

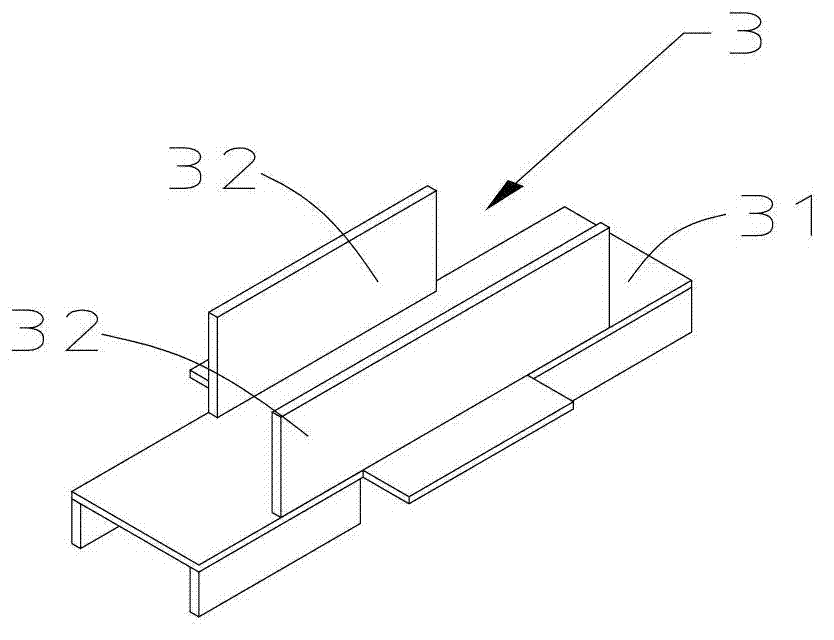

[0012] see Figure 1-3 As shown, a common support structure with coaxial double beams without a machine room, including an intermediate beam 1, two main engine support beams 2 coaxially arranged side by side, a support member 3, and a fastening plate 4. The support member 3 includes 1 The supporting part 31 on the upper surface and the stop part 32 arranged on the opposite sides of the supporting part 31, the longitudinal direction of the main engine support beam 2 extends along the transverse direction of the middle beam 1, and the longitudinal direction of the supporting part 31 of the supporting part 3 It also extends along the transverse direction of the middle beam 1, and both ends of the supporting portion 31 extend out of the middle beam 1, that is to say, the supporting contact area of the supporting portion 31 is larger than the width area o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com