A mold for making preset threaded holes in concrete components and a method for making preset threaded holes

A technology of concrete and threaded holes, which is applied in the preparation of building components on site, building construction, and processing of building materials, etc., can solve the problems of concrete falling off, low work efficiency, and difficulty in operation, and achieves streamlined production and construction speed. Fast, easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

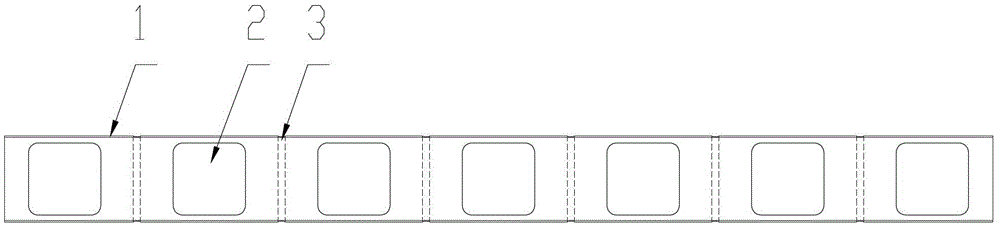

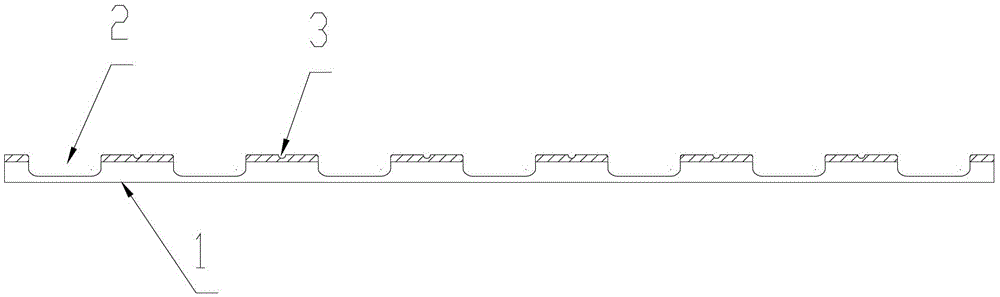

[0065] A kind of mold for making preset threaded holes of concrete members according to the present invention comprises: a threaded mold sleeve 12 for thread forming, an intubation tube 13 for installing the threaded mold sleeve, and a hole-making template 14 for fixing the intubation tube;

[0066] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 ,and Figure 11 as shown,

[0067] The thread pattern sleeve 12 is composed of three thread pattern sheets 1 and a plurality of adjustment coils 4; the adjustment spring coils 4 combine the three thread pattern sheets 1 to form a tubular, diameter-adjustable Size threaded model casing 12.

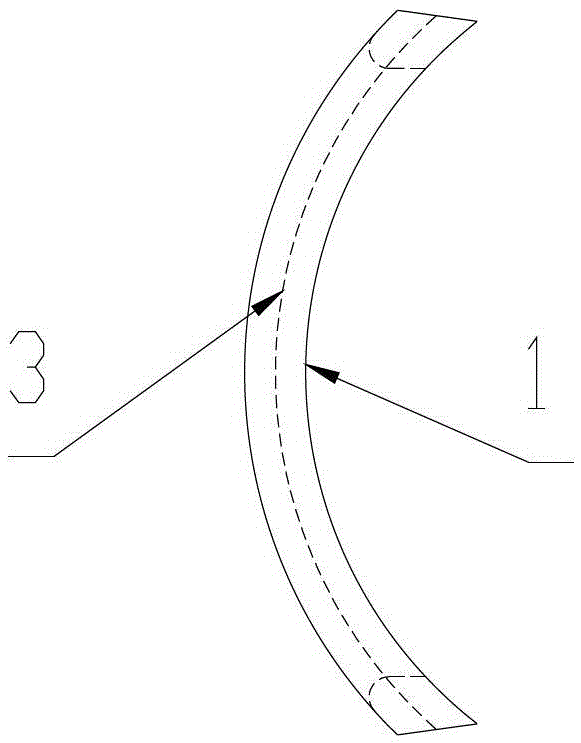

[0068] The thread model piece 1 is formed by injection of hard plastic, and is provided with a plurality of thread forming grooves 2 and adjusting coil positioning grooves 3; the radial section of the thread model piece 1 is arc-shaped, and its inner surface The diameter is the same as the outer diameter of the c...

Embodiment 2

[0097] Embodiment 2 of a mold for making preset threaded holes of a concrete member and its manufacturing method according to the present invention optimizes the structure of the threaded model casing 12 described in Embodiment 1, and the rest are the same as those described in Embodiment 1. Described are exactly the same, in embodiment 2, do not make duplicate description.

[0098] Such as Figure 17 , Figure 18 , Figure 19 and Figure 20 as shown,

[0099]The thread pattern sheet 1 is formed by injection molding of elastic plastic, and is provided with a thread forming groove 2 and a positioning groove 3 for adjusting coils.

[0100] The thread model sheet 1 is spiral, and considering that the thread model casing 12 will be taken out from the threaded hole made, so, in a free state, the outer diameter of the spiral thread model sheet 1 is smaller than the threaded hole. The outer diameter of the cannula main body 5 (such as Figure 10 shown); the thread forming groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com