Kind of Ply Yarns and Ply Yarns Fabric

a technology of ply yarn and fabric, which is applied in the field of textiles, can solve the problems of increasing the cost of fabrics, the method of producing untwisted yarns will pollute the environment seriously, and the cost of solving the kind of pollution is high, so as to achieve the effect of reducing waste and cost, high tensile strength and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

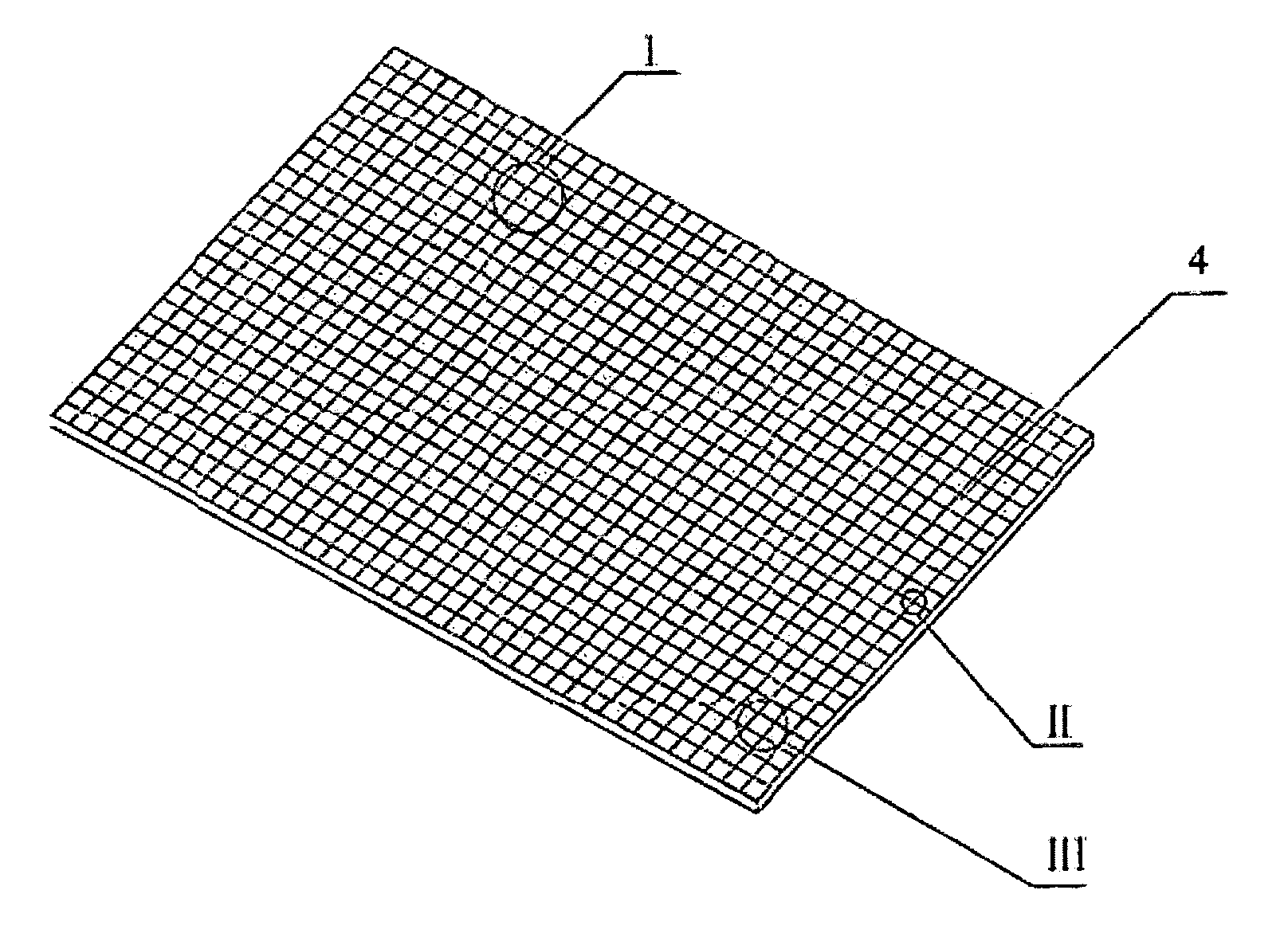

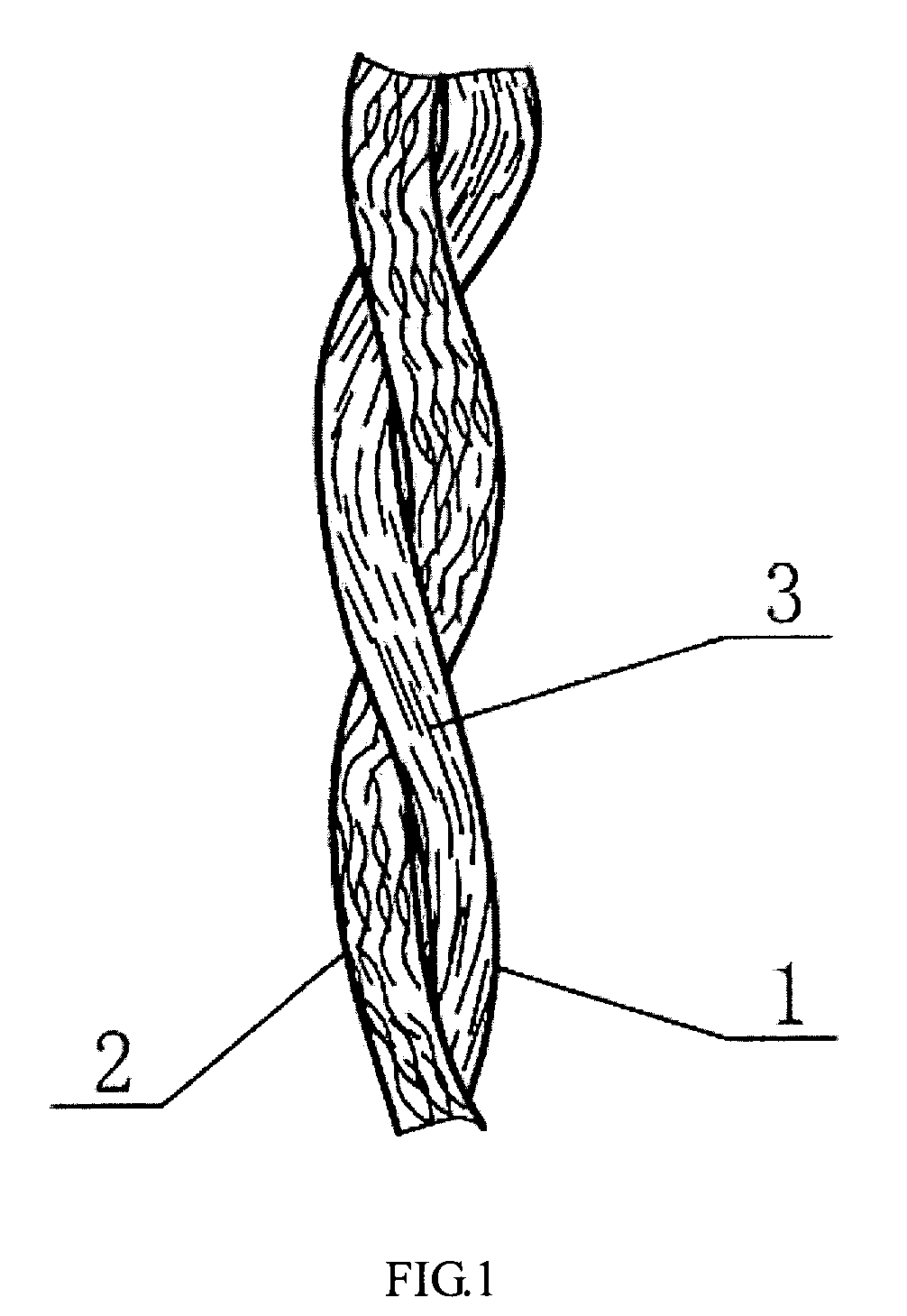

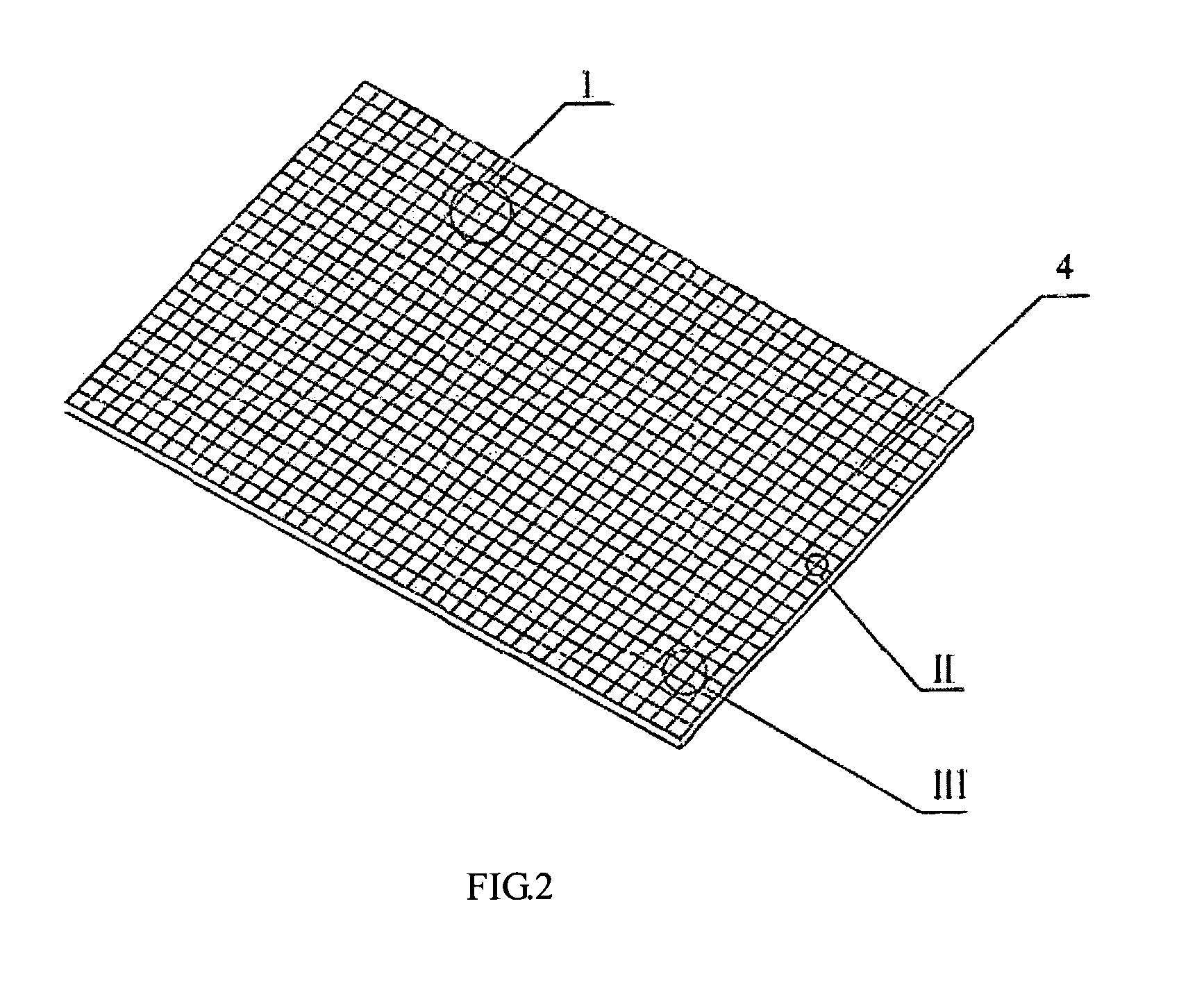

[0017]In FIG. 1, said ply yarn being made by intertwisting one piece of untwisted yarn 1 and one piece of twisted yarn or filament 2 in a direction of the length. The twist factor of the untwisted yarn 1 is below 200, and the fibers 3 of the untwisted yarn 1 are parallel. The ply yarns have many combined arrangements, for example, the untwisted yarn 1 and the twisted yarn 2 are linear, the untwisted yarn 1 intertwistes the twisted yarn 2 linearly; the untwisted yarn 1 is curvilinear, the twisted yarn 2 is linear, the untwisted yarn 1 intertwistes the twisted yarn 2 in the direction of the length; the circularity is set on the untwisted yarn 1, the circularity is set on the twisted yarn 2, the untwisted yarn 1 intertwistes the twisted yarn 2 in the direction of the length; the circularity is set on the untwisted yarn 1, the twisted yarn 2 is linear, the untwisted yarn 1 intertwistes the twisted yarn 2 in the direction of the length. The twisted yarns as described above also can be re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| softness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com