Cushioned self-tightening freezer drawers

A technology for drawers and refrigerators, applied in the field of drawers for refrigerators, which can solve problems such as door seal cracking, cabinet vibration, and reduced service life, so as to prolong the service life, avoid impact, and reduce damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

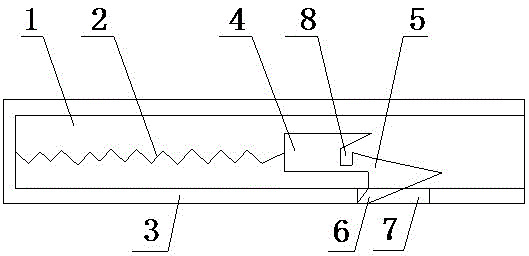

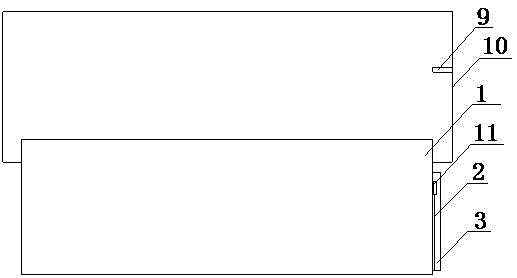

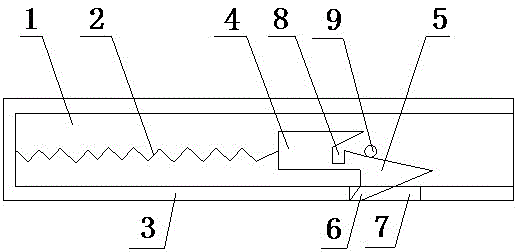

[0019] The buffer self-tightening freezer drawer of the present embodiment, as figure 1 with figure 2 Shown, freezer 10 is provided with stop post 9 on the inner wall opposite to drawer 1 side, and stop post 9 is cylindrical; The side of drawer 1 is provided with L-shaped support 3; The L-shaped horizontal side of support 3 is shaped on Hook hole 7, spring 2 is fixed on the vertical side of support 3L shape, and spring 2 adopts tension spring in the present embodiment, and spring 2 is in the state of stretching all the time, and the other end of spring 2 is fixed toward described drawer tail. Be connected with special-shaped plate 11, special-shaped plate 11 is divided into two baffle plates 4 and hook plate 5 that link to each other, the bottom of hook plate 5 is shaped on the hook 6 that can hook hook hole 7, and the appearance of hook 6 is pointed. The junction of the baffle plate 4 and the hook plate 5 is formed with a groove 8 which is at the same level as the blocking ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com