Oil seal

A technology of oil seals and sealing parts, which is applied in the direction of engine components, engine seals, mechanical equipment, etc., can solve problems such as oil leakage, and achieve the effect of improving sealing and fixing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0075] Next, embodiments of the present invention will be described with reference to the drawings.

no. 1 example

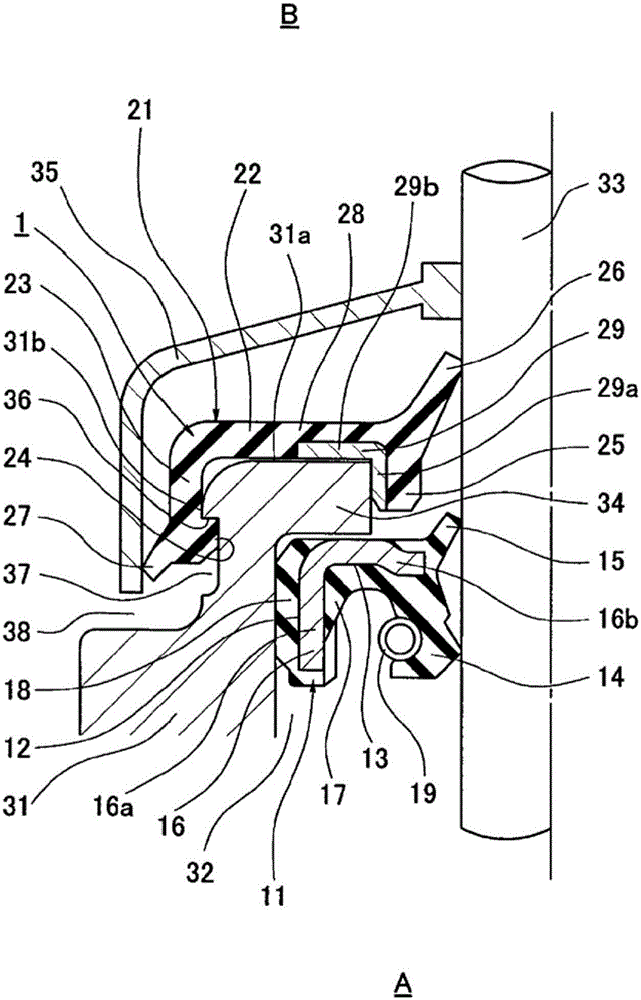

[0077] figure 1 A main part cross section of the oil seal 1 according to the first embodiment of the present invention is shown. The oil seal 1 according to this embodiment is installed on the end surface of the housing 31 through the first sealing member (also referred to as the oil seal main body) 11 installed on the inner periphery of the shaft hole 32 of the housing 31 and the opening peripheral portion of the shaft hole 32 . It is formed by combining the second sealing member (also referred to as a dust seal) 21 of the part, and is configured as follows. In addition, the shaft 33 inserted into the shaft hole 32 is a vertical shaft, specifically, a steering shaft in a power steering unit of a vehicle such as an automobile. The bottom of the figure is the inside A of the machine, and the top is the outside B of the machine. At the outer end of the casing 31, an inward (radially inward) flange portion 34 is integrally provided on the periphery of the shaft hole opening. ...

no. 2 example

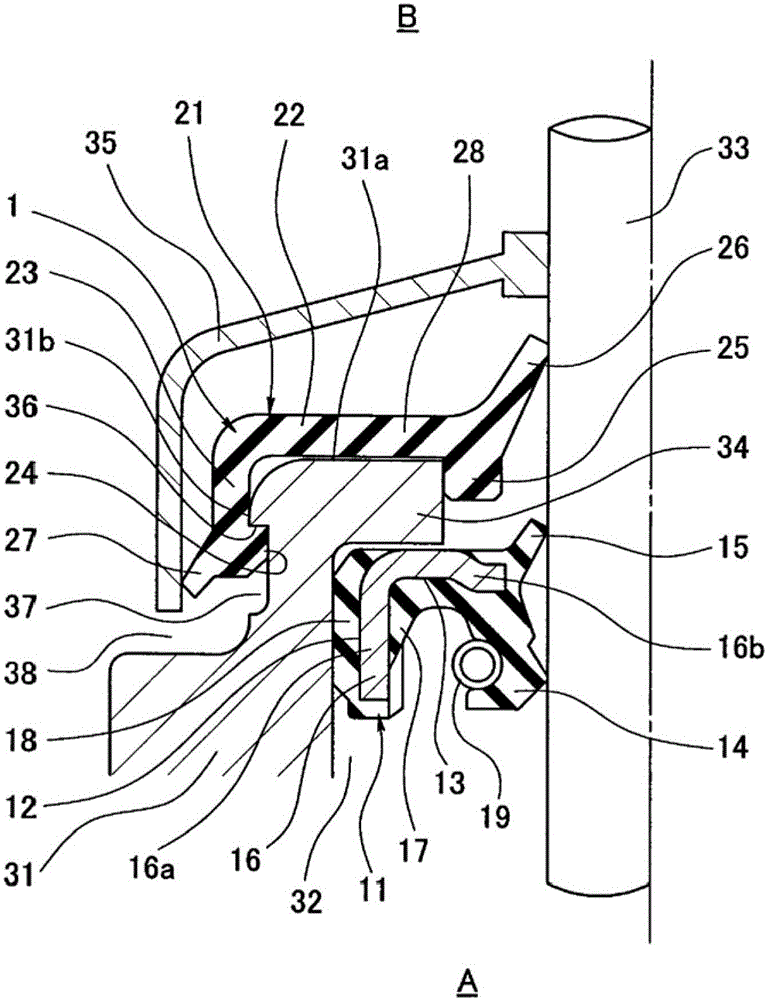

[0086] In the above-mentioned first embodiment, the second sealing member 21 is formed by the integral molding of the rubber-like elastic body 28, and at the same time, the metal ring 29 is embedded in the position from the end surface covering part 22 to the inner peripheral insertion part 25 to increase its strength. But as a second example, as in figure 2 As shown, the metal ring 29 may be omitted, and in this case, the second sealing member 21 is molded only from the integral molding of the rubber-like elastic body 28 . In this case, although the strength is slightly lowered, the manufacturing cost of the second sealing member 21 can be reduced, and since the flexibility of the member is improved, the installation work can be facilitated. Other configurations and functions and effects of this second embodiment are the same as those of the above-mentioned first embodiment. In addition, similar to the first embodiment, the lower end of the inner peripheral insertion portio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com