Connection structure between the shell of the coffee machine and the water outlet slider

A connection structure and technology for coffee machines, applied in the field of parts of coffee machines, can solve problems such as large wear, inability to stick, and short service life, and achieve the effects of small wear, smooth and easy moving process, and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

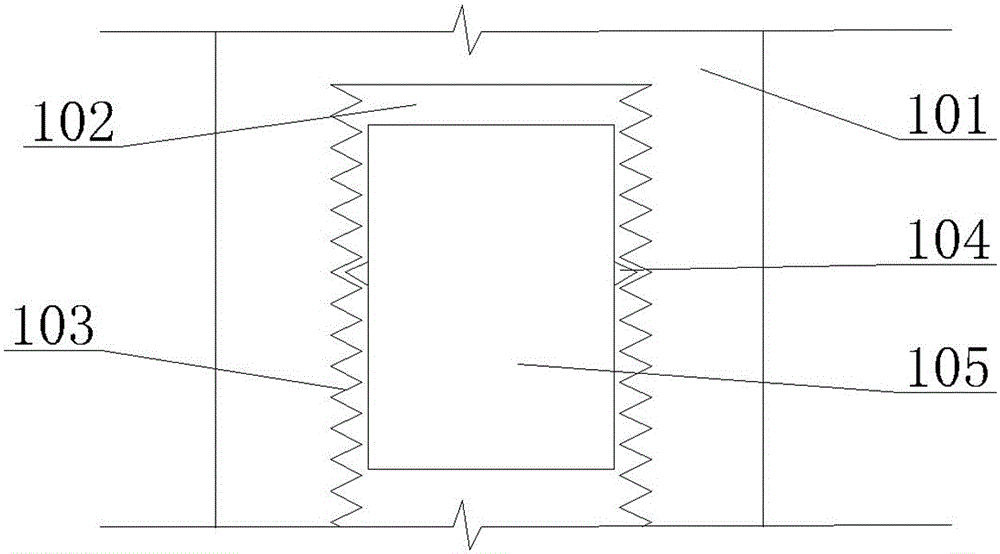

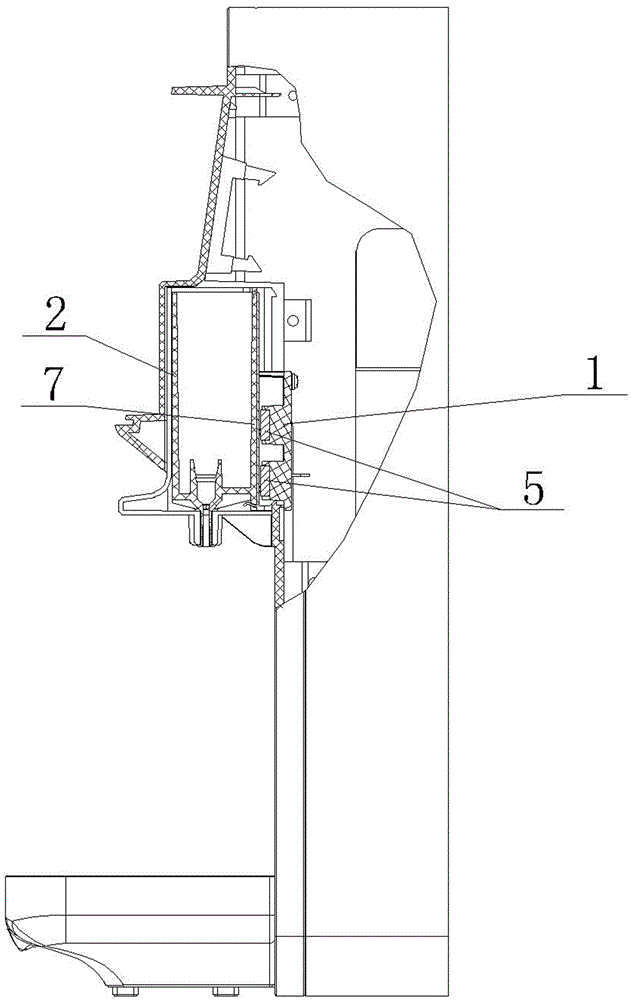

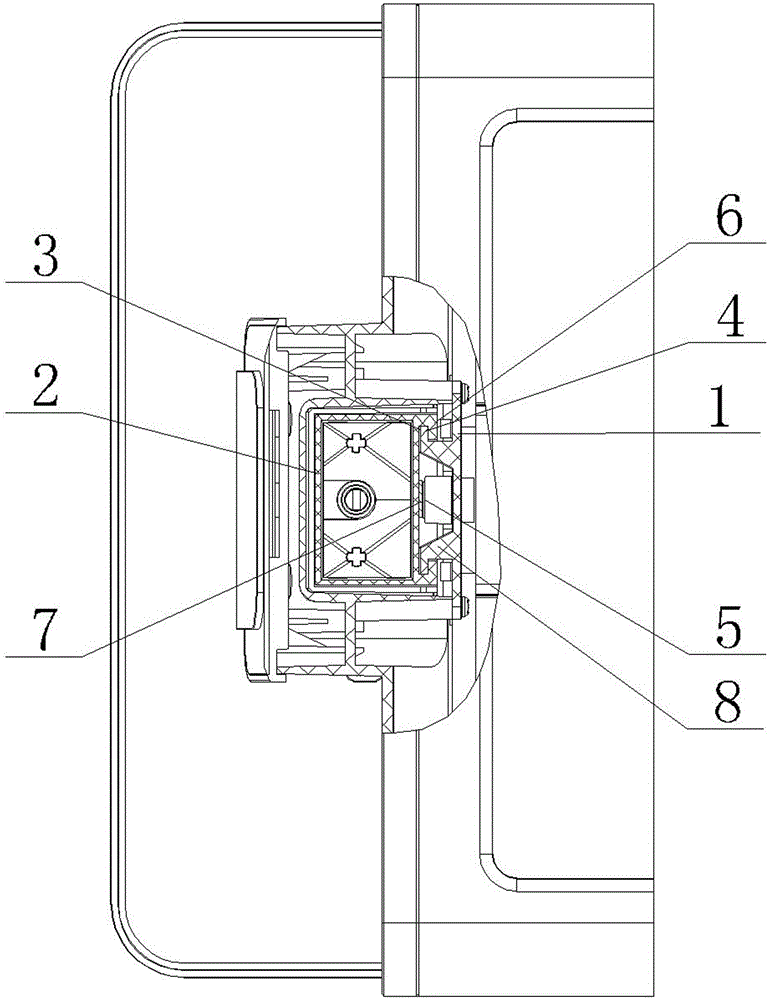

[0020] Such as figure 2 , image 3 , Figure 4 , Figure 5 As shown, the connection structure between the shell of the coffee machine of the present invention and the water outlet slider is as follows. Between the casing 1 and the water outlet slider 2, a male-female vertical chute 3 and a slide bar 4 are provided, that is, an L-shaped plate 6 is provided on both sides of the rear plate of the water outlet slider 2, and each L-shaped plate The gap between 6 and the back plate of the water outlet slider 2 constitutes a vertical chute 3; there are two slide bars 4, both of which are fixed with the shell 1, and the two slide bars 4 are connected with the two vertical There is a one-to-one correspondence to the chute 3, and each slide bar 4 is slidably fitted in the chute 3 corresponding to the chute 3 one-to-one. More specifically, two verti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com