Cable perforating tower joint

A technology of lap joints and cables, applied in the direction of cable joints, etc., can solve the problems of difficult to pass through the jacking pipe and large arc of the jacking pipe.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

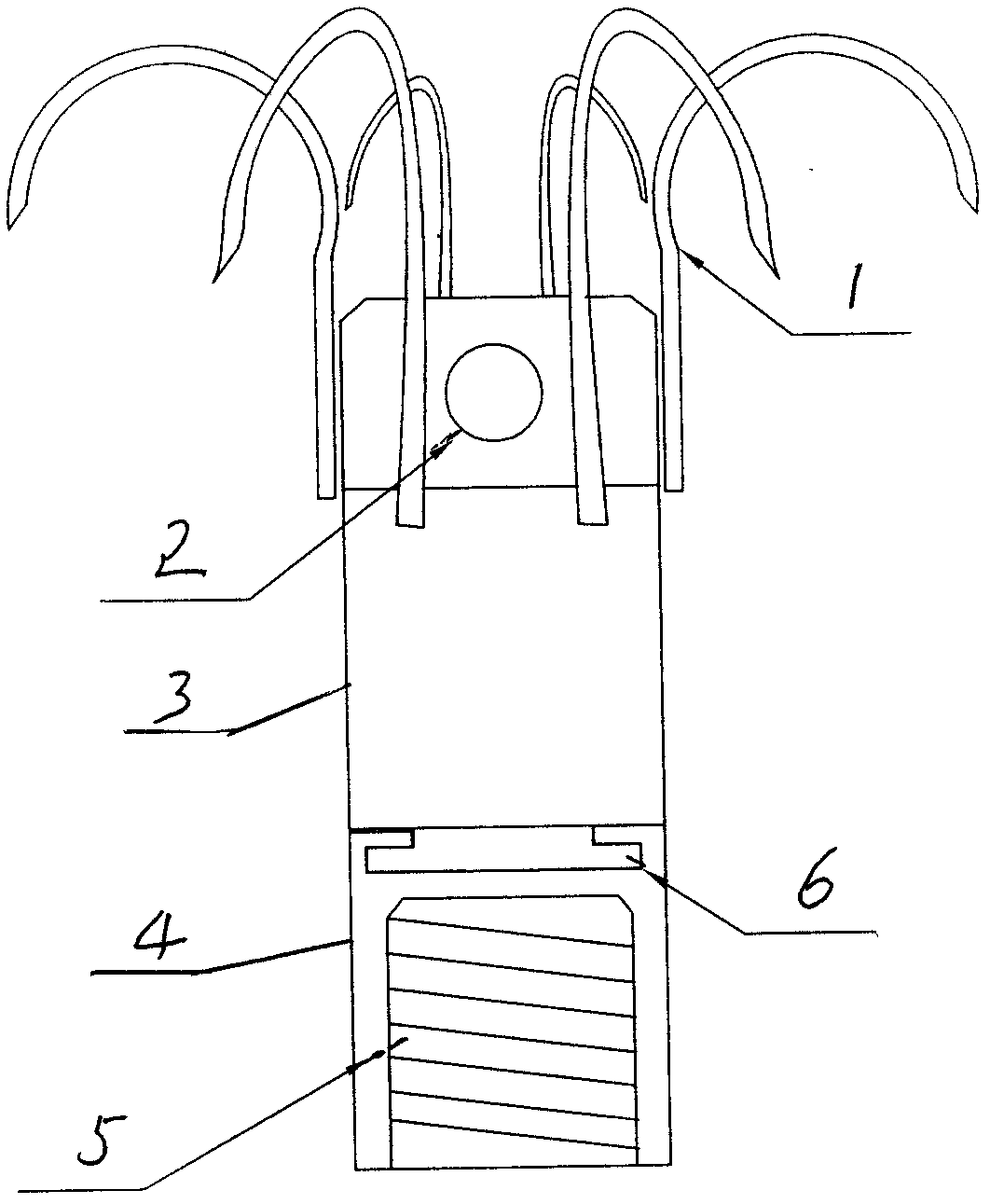

[0006] The embodiment is described in detail in conjunction with the above drawings. A bushing 4 is connected downward with a pin shaft 6 at the lower end of an upper joint 3, and six hooks 1 are evenly distributed outward on the circumferential wall at the top of the upper joint. A pull hole 2 opened to the other side is provided between any two hooks, and a connecting bolt 5 is provided on the wall of the inner hole of the casing, which can facilitate the connection with the front end of the threader. When the cables with relatively long jacking pipes and relatively large radians are connected with threaders, when the two threaders pass through the jacking pipe with a distance of more than 140 meters, one end will start to pull back, and when the hooks on the two threaders are connected, it will They will hook each other, which not only greatly improves the labor efficiency, but also increases the safety.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com