A connecting mechanism for a locomotive and a radial mechanism for a locomotive three-axle bogie

A technology of connecting mechanism and frame, applied in the direction of bogies, railway car body parts, transportation and packaging, etc., to achieve the effect of improving the curve passing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

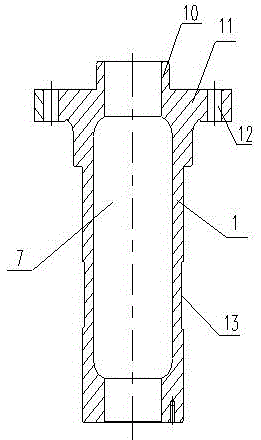

[0017] A linkage mechanism for a locomotive comprising a pivot such as figure 1 As shown, the pivot includes the pivot shaft body 1 and the positioning end 10 at the top of the pivot shaft body 1, the inside of the pivot shaft is provided with a weight-reducing hole 7, and the outer wall of the pivot shaft body 1 mounting spacer 8 is provided with a direction toward the pivot shaft body 1. The groove section 13 in the center of the shaft body 1 is depressed, and the lower side of the positioning end 10 is provided with a mounting surface 11 whose radius is larger than that of the positioning end 10 , and mounting holes 12 are symmetrically provided on the mounting surface 11 .

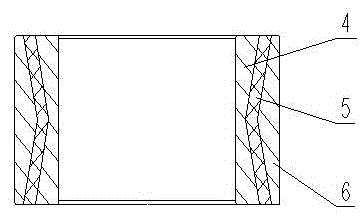

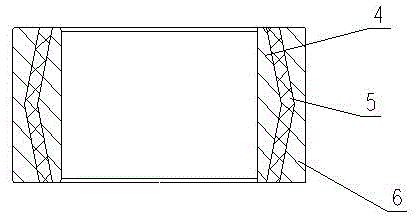

[0018] The pivot shaft body 1 is covered with a rubber joint 2, and the rubber joint includes an inner sleeve 4, an outer sleeve 6, and a rubber layer 5 arranged between the inner sleeve 4 and the outer sleeve 6, such as figure 2 As shown, the rubber layer 5 is bent towards the inner sleeve 4, such as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com