Construction method of pouring multi-label concrete joints in frame structure

A technology of frame structure and construction method, which is applied in the direction of architecture, building structure, and construction material processing, etc., can solve problems such as poor construction quality, and achieve the effects of good reference significance, fast construction, and good social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0019] A pouring construction method for multi-marked concrete nodes of a frame structure, comprising the following steps:

[0020] (1) According to the frame structure design and construction plan, the frame column reinforcement is bound;

[0021] (2) According to the construction plan, carry out the formwork support construction of frame columns, beams and slabs;

[0022] (3) According to the structural design and construction plan, the beams and slabs are bound with steel bars;

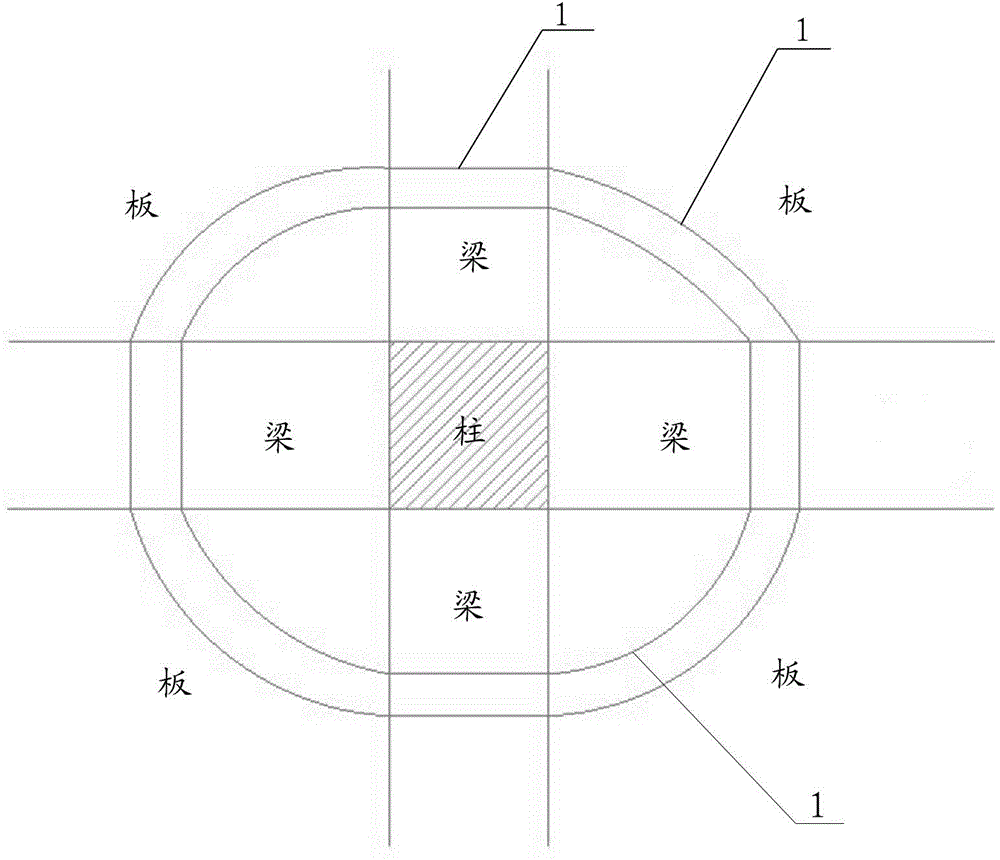

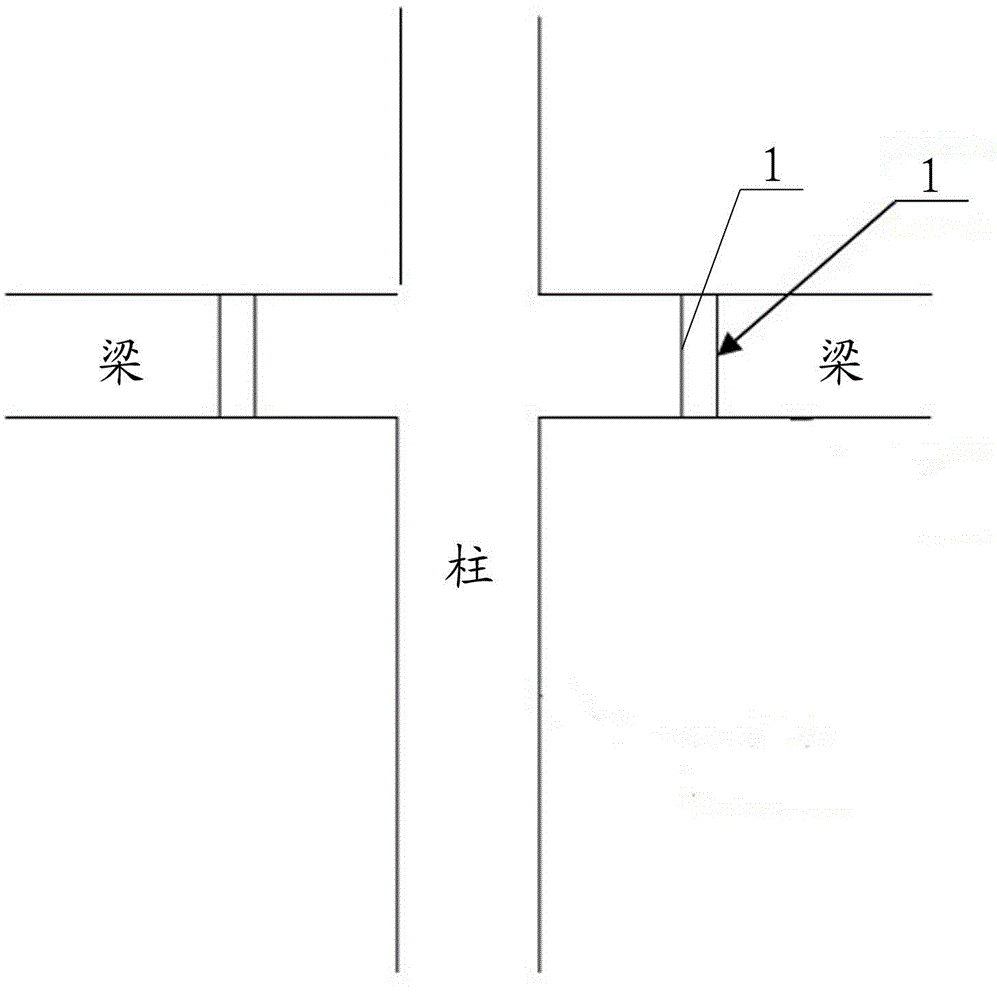

[0023] (4) Bind the steel wire mesh 1 vertically around the frame column in the bound beam and slab reinforcement, and the steel wire mesh 1 is 500-600mm away from the periphery of the frame column, such as figure 1 , 2 shown;

[0024] (5) Concrete pouring: pour the high-grade frame column concrete first, and when a frame column is poured, immediately pour the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com