Plug pin formed using an extrusion process

A technology of plug pins and extrusion molding, which is applied to the connection of permanent deformation, the parts of the connection device, and the manufacture of contact pieces, which can solve the problems of inapplicability and achieve the effect of saving price and saving transportation weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

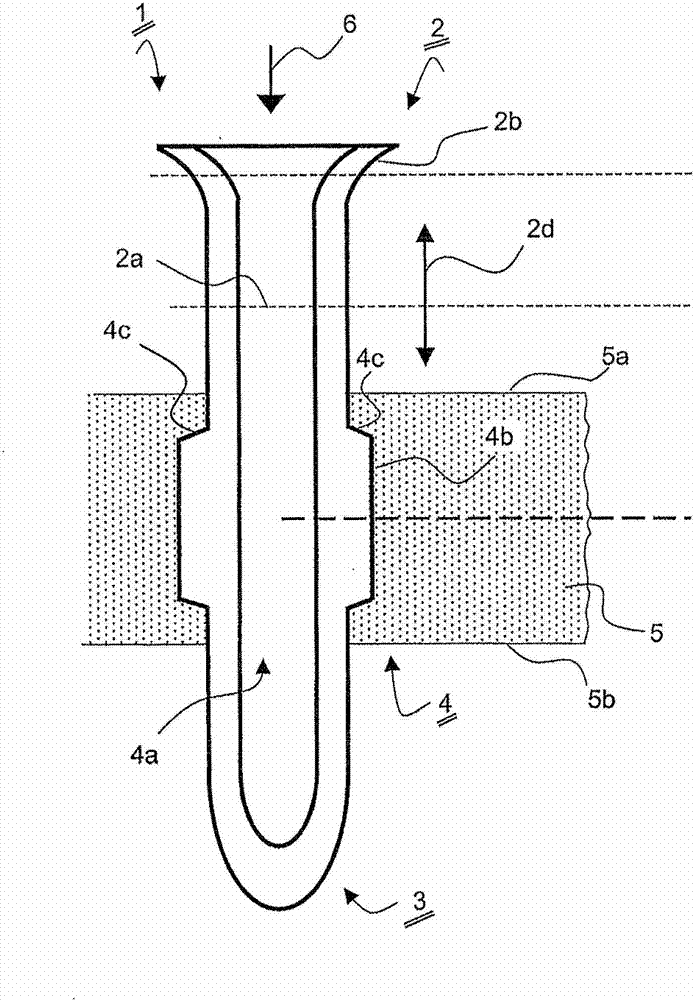

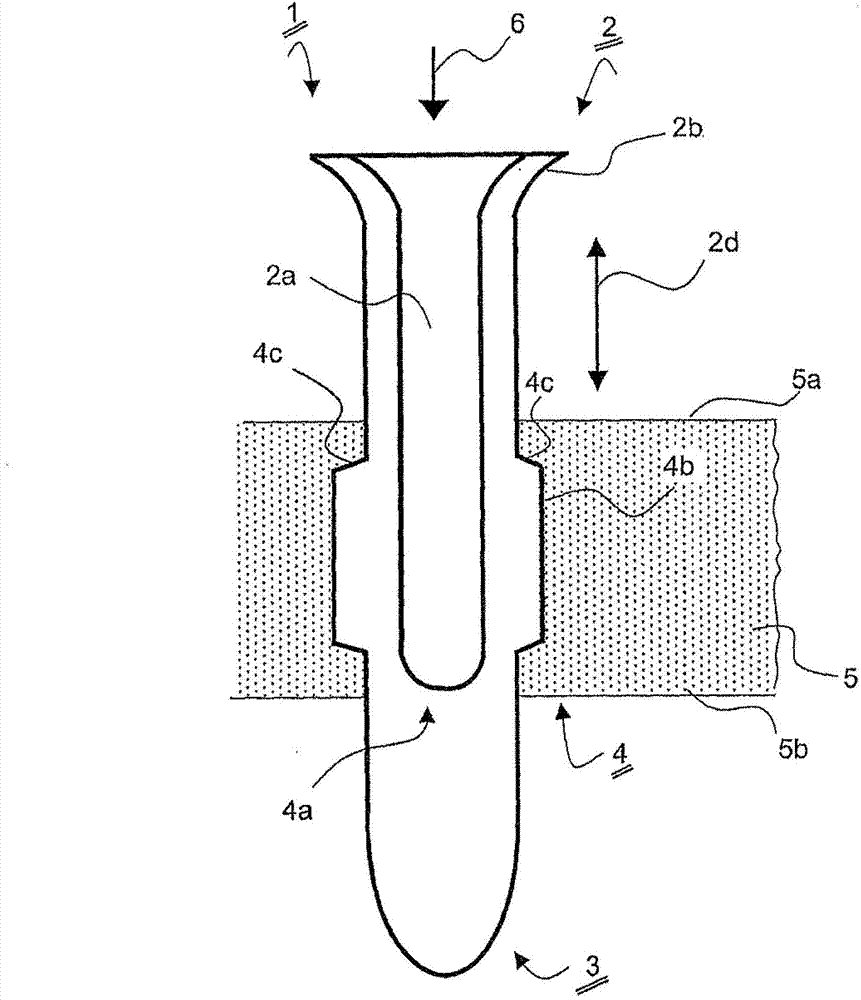

[0036] according to Figure 1a , the plug pin generally denoted by 1 comprises a connection end 2 for connecting a not shown power supply stranded wire, and an extruded central area 4 leading from the connection end 2 to the contact end 3 on the socket side, wherein , the central region 4 is hollow, as indicated by the cavity 4a, and the connection end 2 is formed as a clamping end 2a.

[0037] The plug pins 1 are used in this example for a double-secured plug and are injected into a plug bridge base 5 made of plastic during use. The plug pins are made of a specially conductive material, preferably brass which can be used here. The availability of other metals, particularly stainless steel, has been thoroughly described and published.

[0038] A funnel-shaped extension 2b is provided on the connection end 2, which makes it easier to push in the power supply strands, for example from the direction indicated by the arrow 6, without the strands affecting the safety of the finish...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com