Fabric compressor

A technology of compressors and textiles, applied in the field of compressors, can solve the problems of time-consuming and labor-intensive, shortening the service life of hydraulic compressors, increasing maintenance costs of compressors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

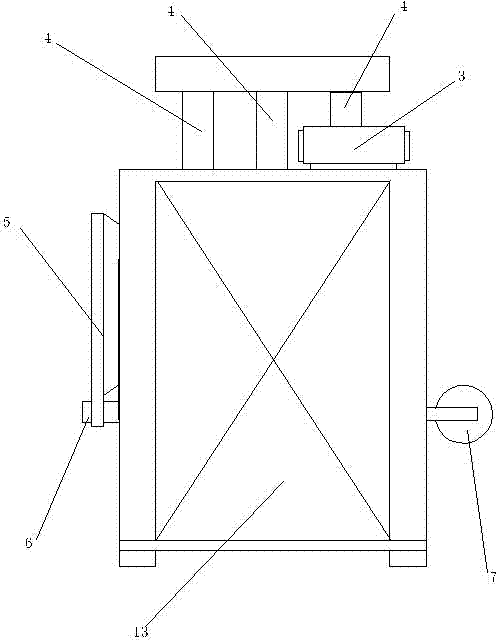

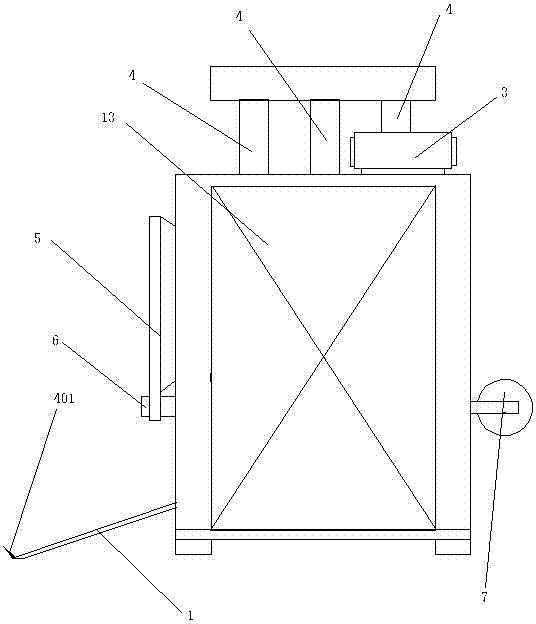

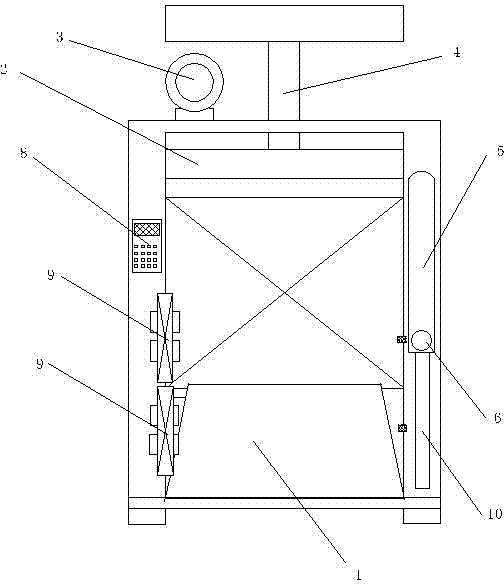

[0021] Example 1: see figure 2 , image 3 , Figure 4 , Image 6 , Figure 9 Shown: a compressor, including a controller 8, a front panel 11, a rear panel 12, a left panel 14, a right panel 13, two vertically placed first slideways 204 inside the left panel 14, the first slideway Two racks are arranged in the 204, and a motor is provided to drive the racks to run. There are two vertically placed second slideways 201 in the right panel 13, and the second slideway 201 is provided with two racks, and is provided with a motor to drive the racks to run. A third slideway 206 is placed horizontally on the two first slideways 204 , and a gear that cooperates with the inner rack of the first slideway 204 is arranged on the third slideway 206 . There are fourth slideways 203 placed horizontally on the two second slideways 201 , and gears...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com