Current sensor

A current sensor, current technology, applied in the direction of voltage/current isolation, measuring current/voltage, instruments, etc., can solve the problems of reduced measurement accuracy, no mention of the influence of residual magnetic field, residual magnetic body, etc., to achieve improved measurement accuracy, Excellent current detection characteristics, effect of reducing residual magnetic field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

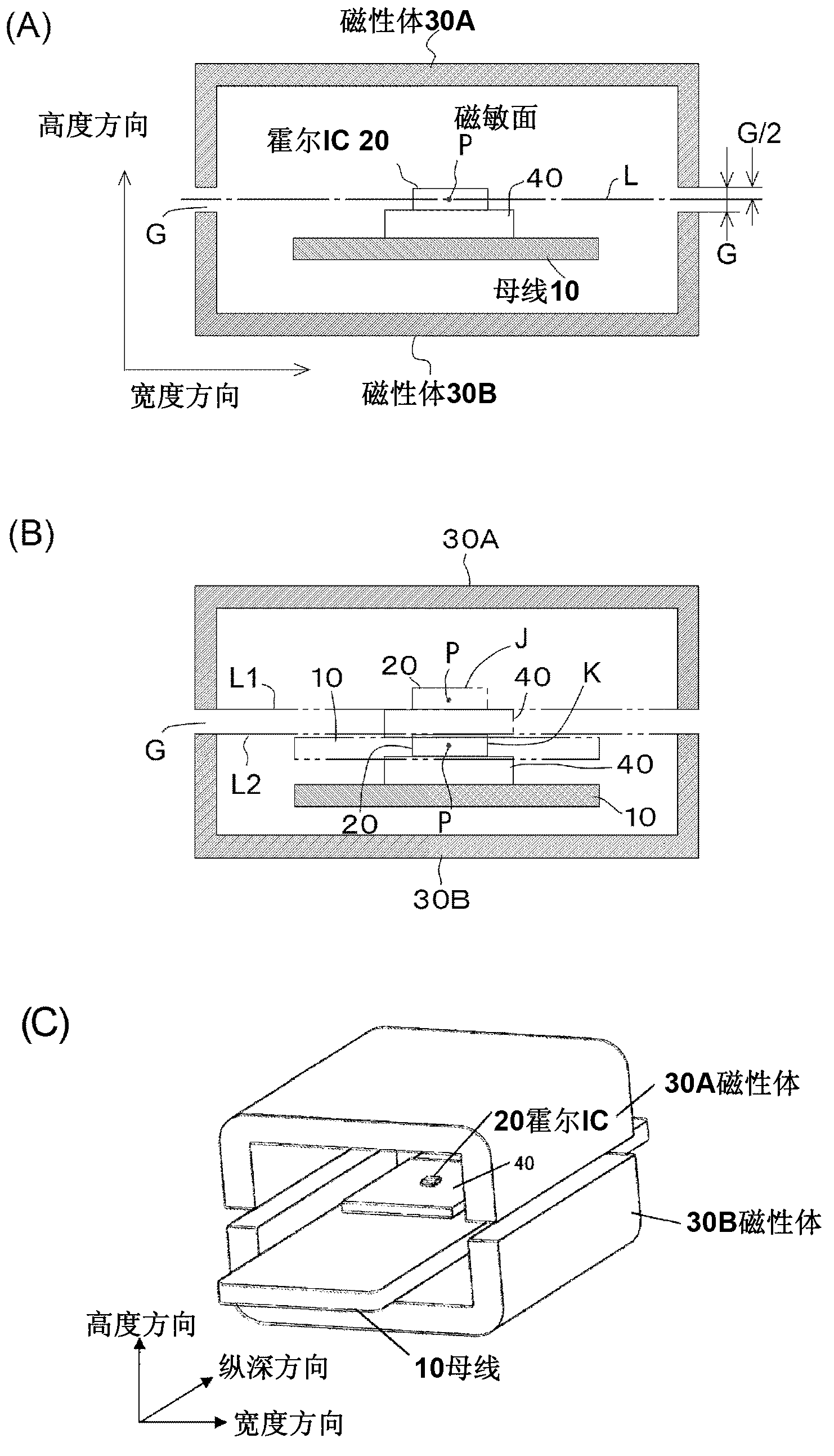

[0045] Below, while referring to the attached Figure 1 Preferred embodiments of the present invention will be described in detail. In addition, the same or equivalent constituent elements, members, processes, etc. shown in each drawing are denoted by the same reference numerals, and overlapping descriptions are appropriately omitted. In addition, the embodiment is not to limit the invention but to illustrate, and all the features or combinations thereof described in the embodiment are not necessarily limited to the essence of the invention.

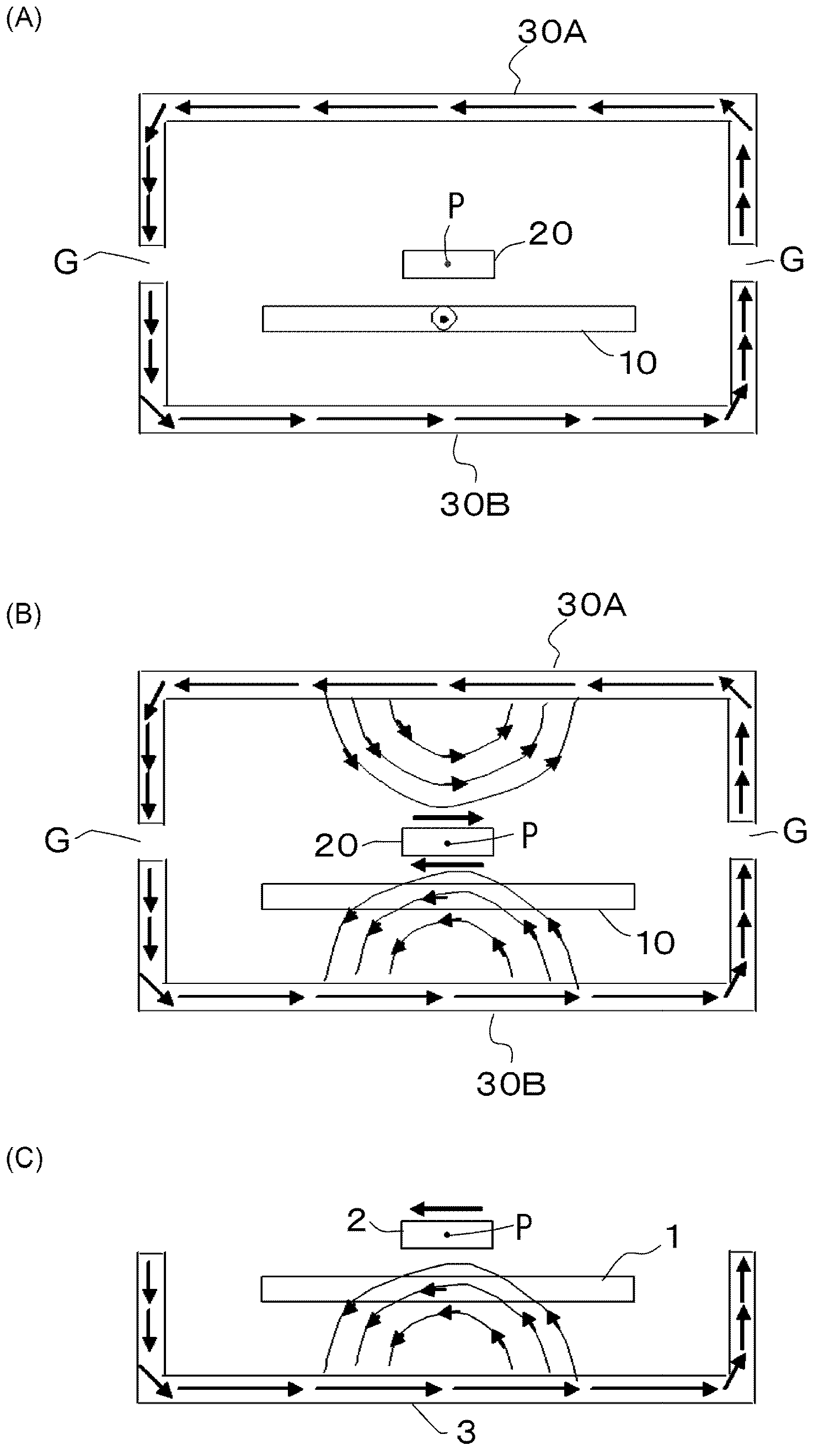

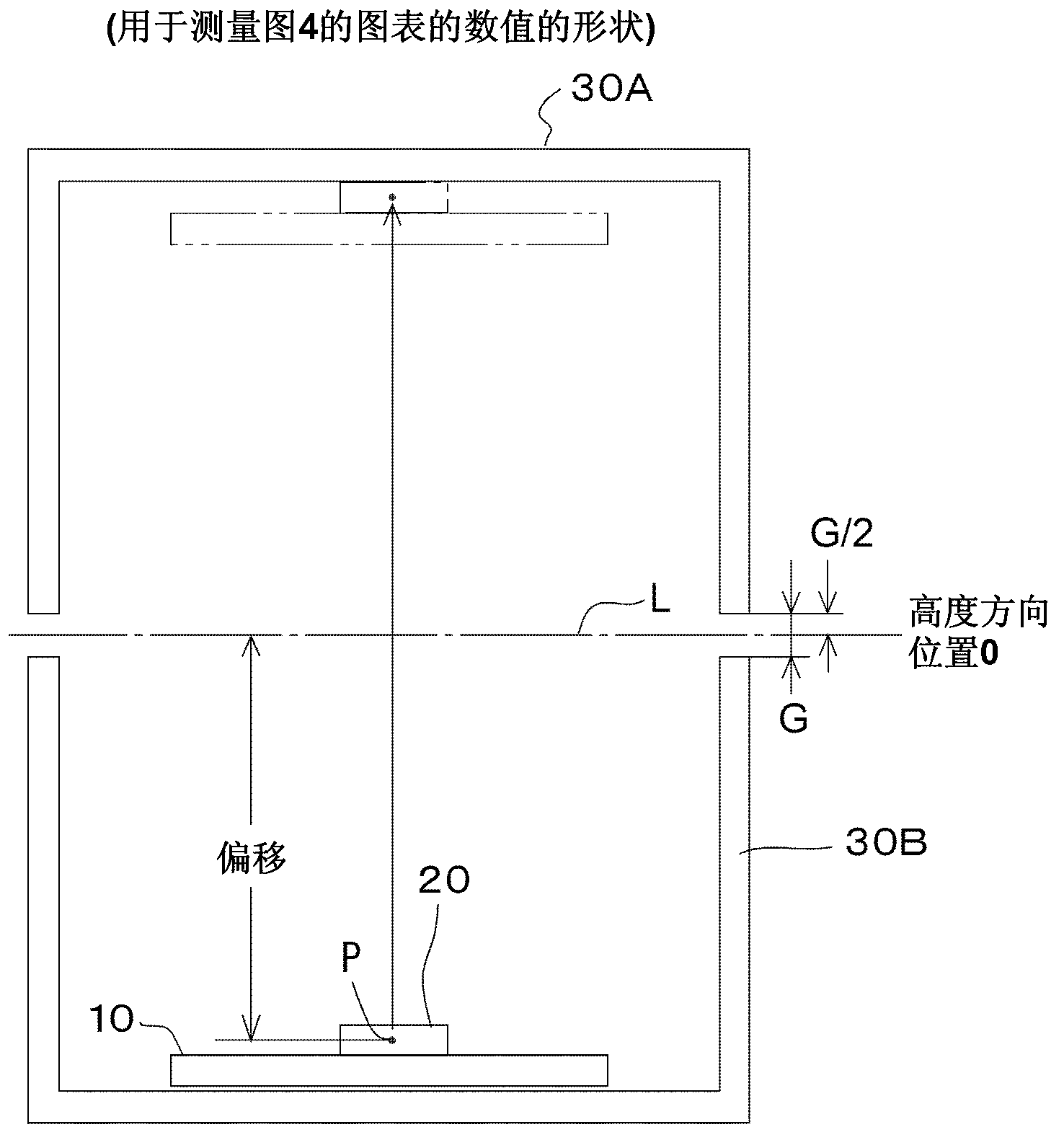

[0046] figure 1 It is the first embodiment of the current sensor according to the present invention, which has a bus bar 10 which is a conductor through which the current to be measured flows, and a magnetosensitive element which is fixedly arranged relative to the bus bar (current conducting part) 10 via an insulating substrate 40 Hall IC 20 , and a pair of first and second cross-sectional U-shaped magnetic bodies 30A, 30B that magne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com