Automatic analysis device

An automatic analysis device and a technology for analyzing items, applied in the field of automatic analysis devices, can solve problems such as inability to properly set and change analysis parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Examples of the present invention will be described using an automatic analyzer using a set of reagent bottles in one cassette.

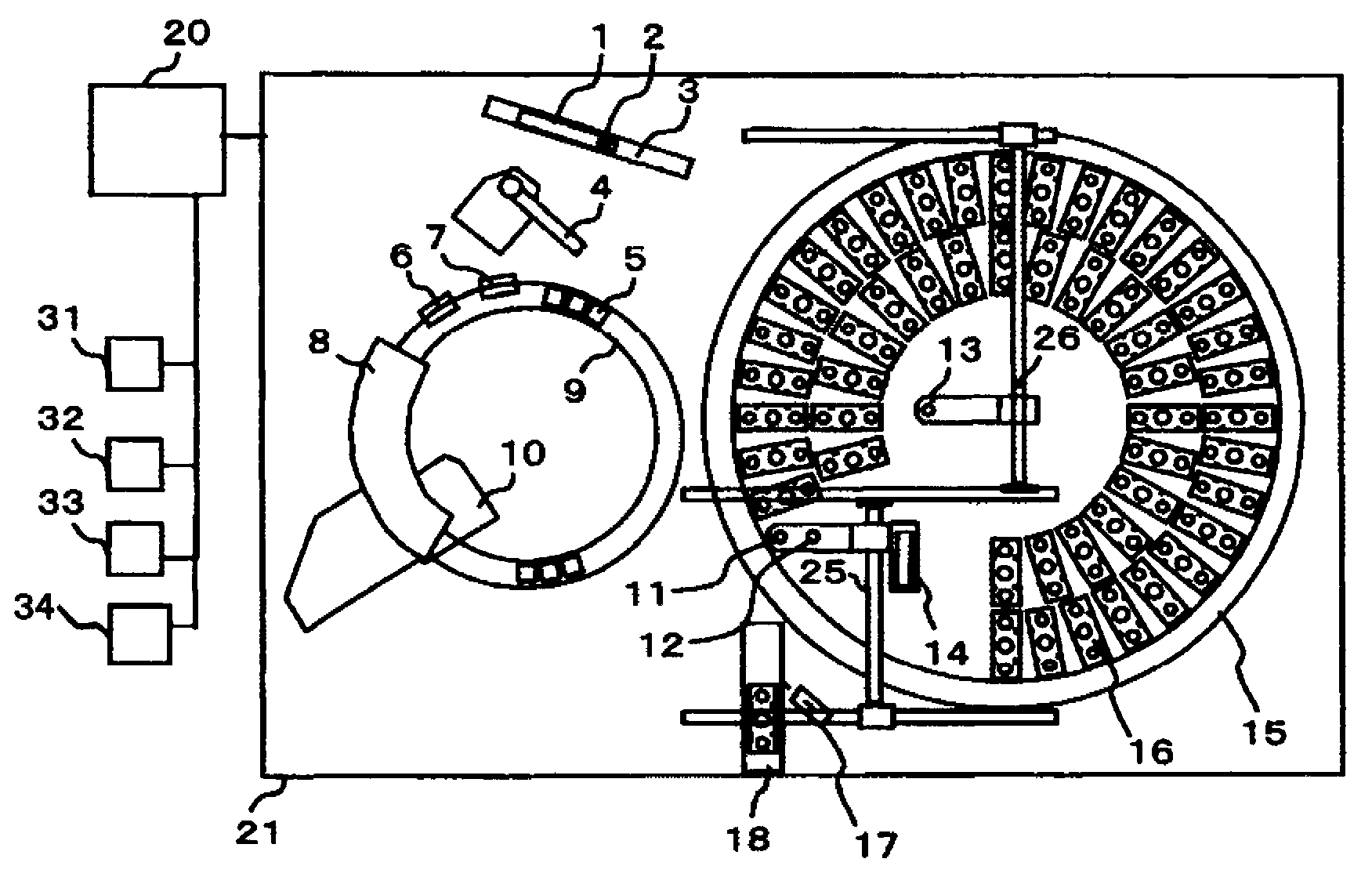

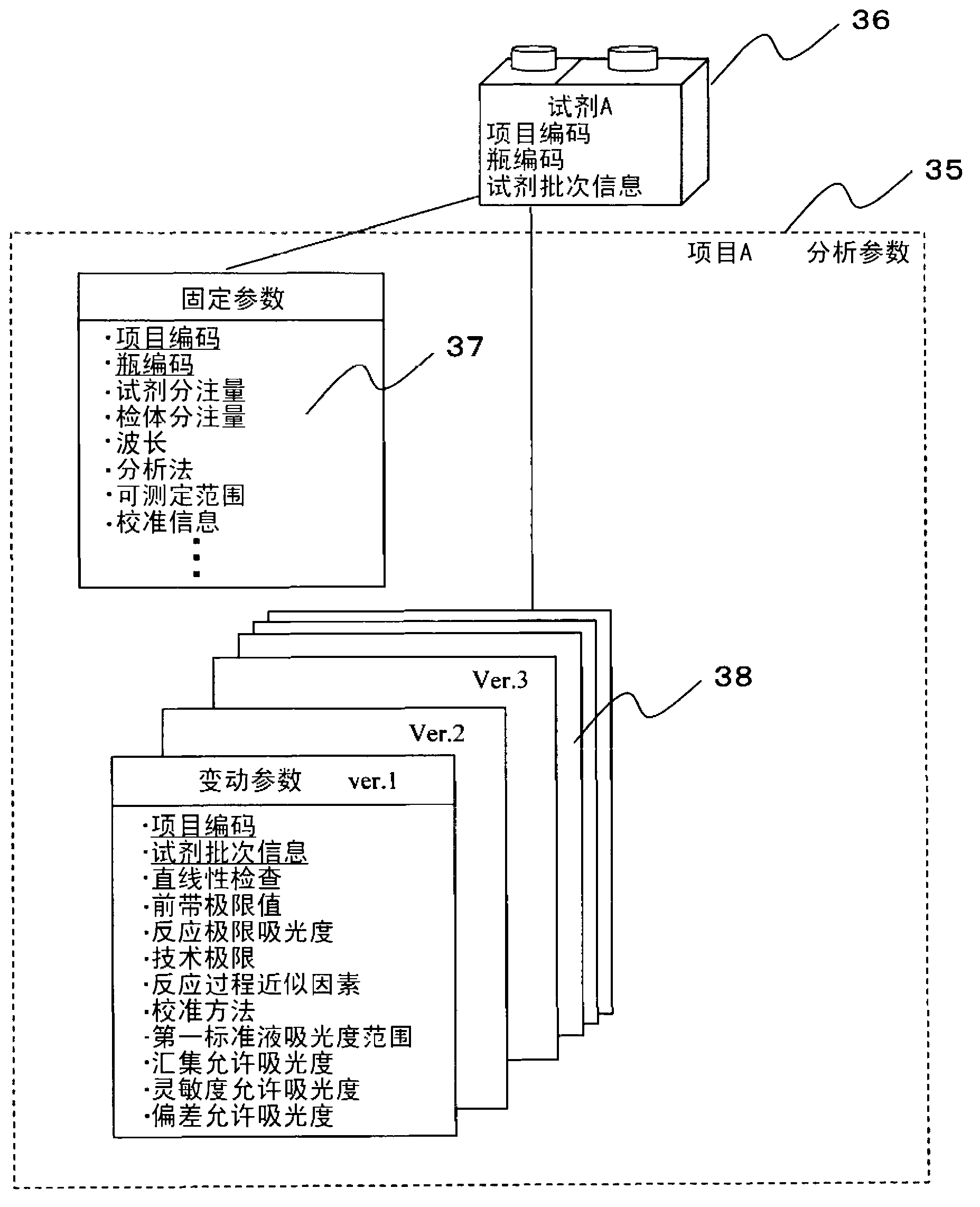

[0037] figure 1 It is a schematic configuration diagram of an automatic analyzer according to Example 1 to which the present invention is applied. figure 1 In the embodiment, a plurality of reaction vessels 5 are arranged on the circumference of the reaction disk 9 on the frame body 21 .

[0038] On the reagent disk 15, a plurality of reagent cartridges 16 can be respectively arranged on the circumference. A maximum of three reagents (first reagent to third reagent) can be accommodated in one reagent cartridge 16 .

[0039] A transport mechanism 3 is provided near the reaction disk 9, and the transport mechanism 3 moves the stage 1 on which the sample container 2 is mounted. Guide rails 25 and 26 are arranged on the reagent disk 15 , and a reagent detector 11 , a reagent unsealing mechanism 12 , and a reagent box conveying mechanism 14 are...

Embodiment 2

[0082] Next, Example 2 of the present invention will be described.

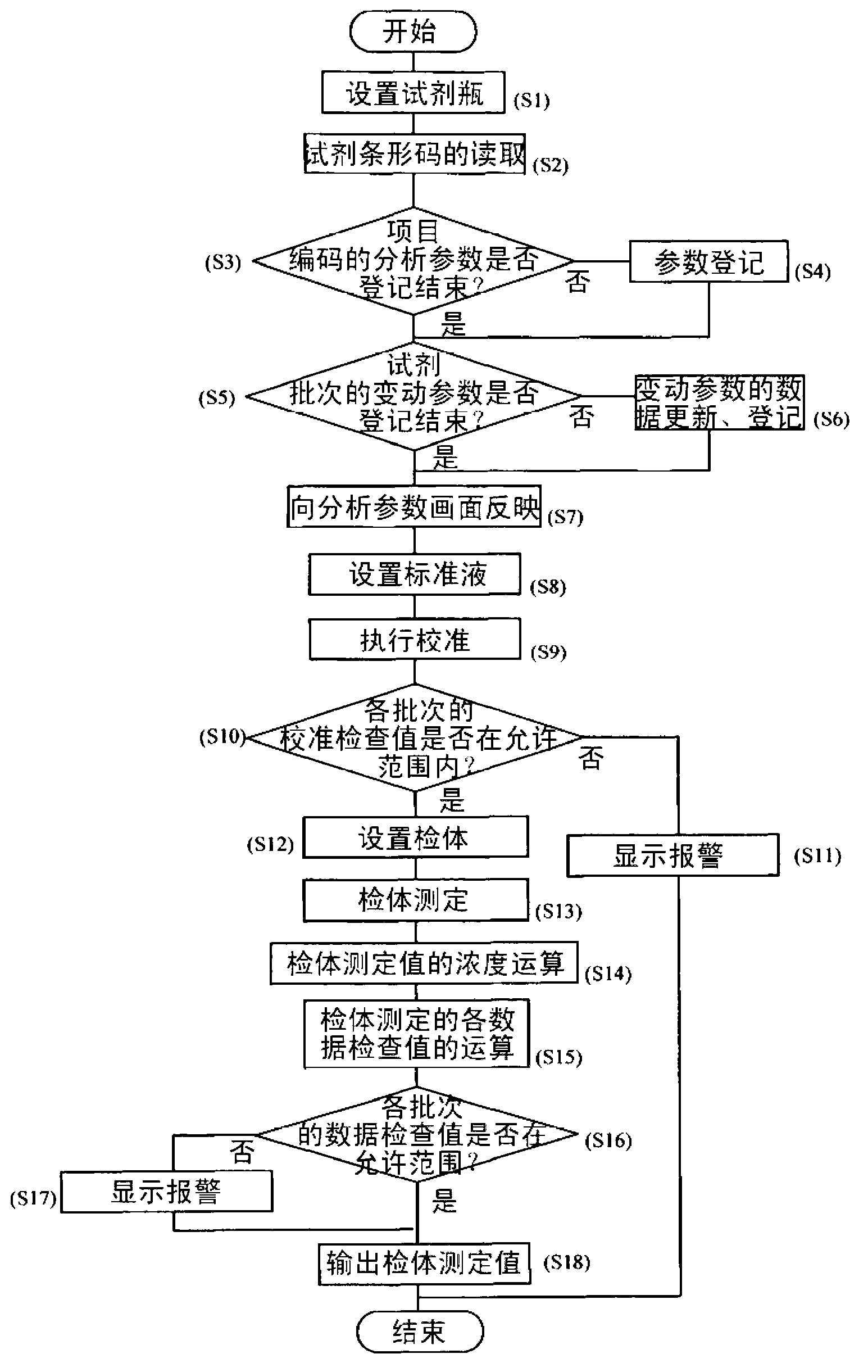

[0083] Embodiment 2 of the present invention is in figure 1 The device structure shown with image 3 The processing procedure shown is the same as that of Embodiment 1, and thus detailed description thereof will be omitted.

[0084] Embodiment 2 of the present invention is used in image 3An example of the case where the control unit 33 performs the time-dependent change of the calculated value and the precision management of the reagent and the device for the calibration check value calculated in Steps 9 and 10.

[0085] In Embodiment 1, it is described that a plurality of fluctuation parameters 38 are stored, and information on reagent batches that have passed a certain period of time is deleted, but in Embodiment 2, by storing a plurality of values of the fluctuation parameters 38 for a long time, and by real-time (Each batch) is displayed so that the user can easily confirm the change in the quality ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com