Inspection specimen pretreatment device and using method thereof

A pretreatment device and specimen technology, applied in chemical instruments and methods, transportation and packaging, chemical/physical processes, etc., can solve problems such as low efficiency, affecting efficiency, and limited number of specimen tubes, so as to avoid personal safety and improve analysis. Liquid efficiency, the effect of improving reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

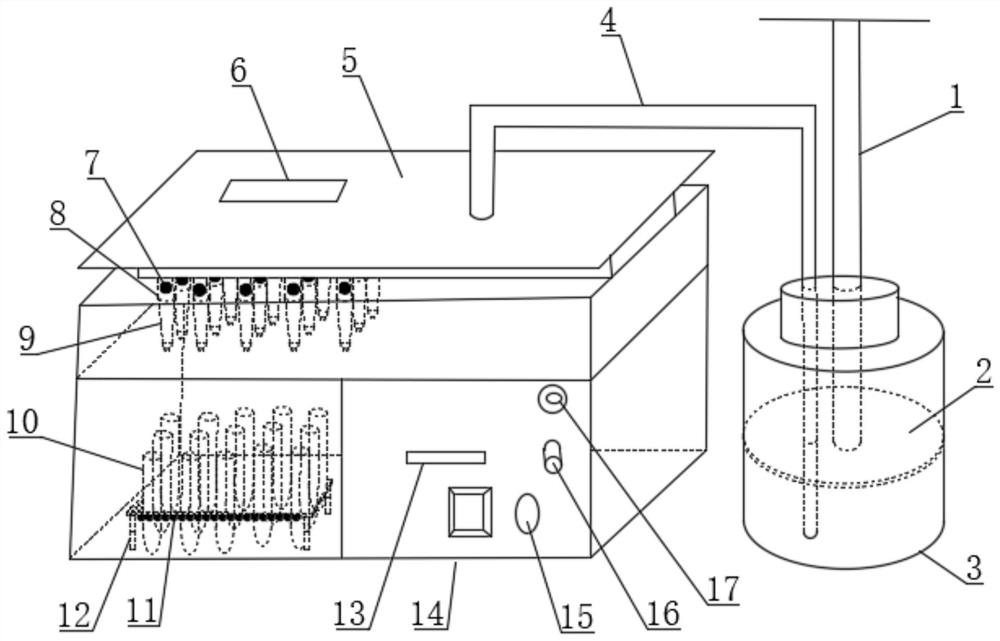

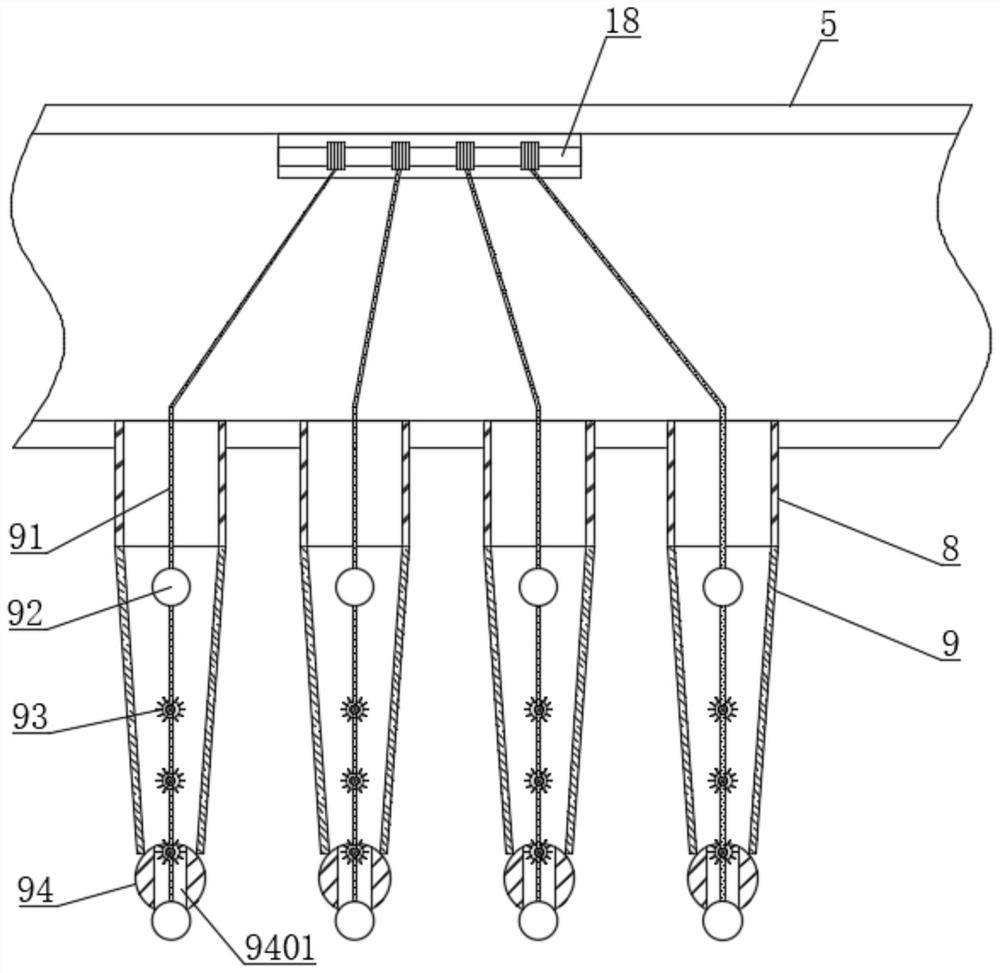

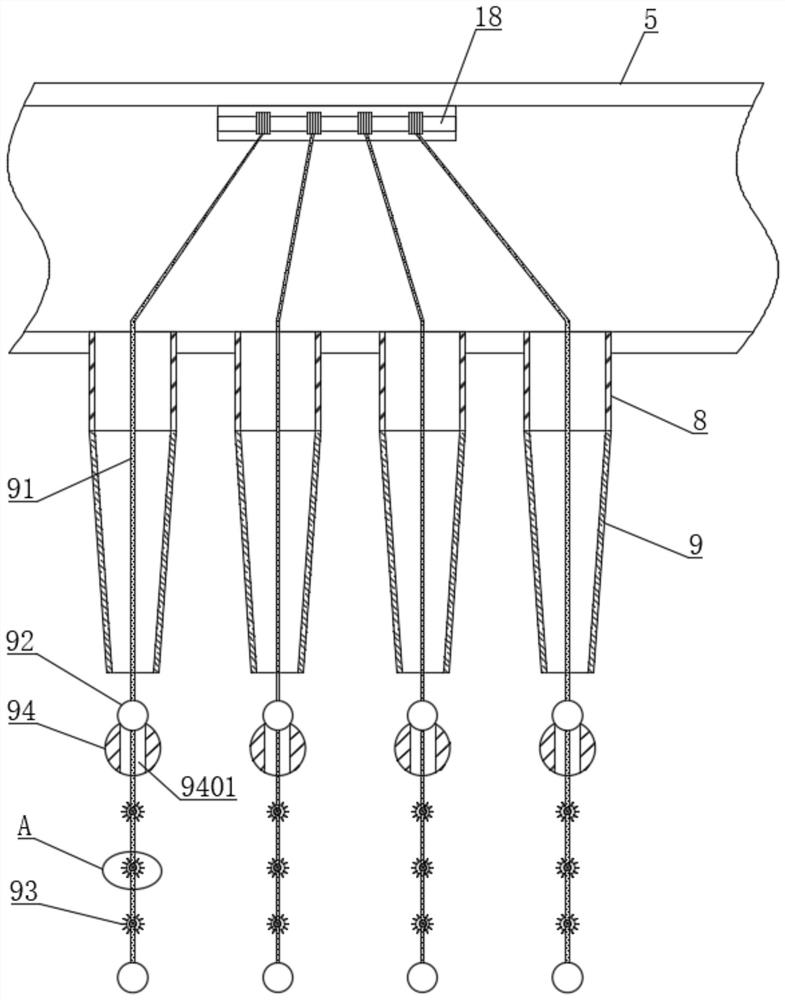

[0041] see figure 1 , a test sample pretreatment device, including a liquid separation device, a timing indicator device and a vibration mixing device, the liquid separation device includes a reagent bottle 3 and a temporary storage room 5, and a transfer tube is connected between the reagent bottle 3 and the temporary storage room 5 4. The upper ends of the reagent bottle 3 and the temporary storage chamber 5 are provided with sockets, and the two ends of the transfer tube 4 are respectively inserted into a pair of sockets, and extend to the inside of the reagent bottle 3 and the temporary storage chamber 5, and the transfer tube 4 and the socket The joints of the transfer tube 4 and the temporary storage chamber 5 are made of opaque materials, such as opaque resin such as polypropylene or materials that do not react with the reagent. The internal sliding connection of the reagent bottle 3 has Built-in pressure pad 2, the upper end of the built-in pressure pad 2 is fixedly co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com