Method achieving rotary machinery vibration signal synchronization order ratio tracing analysis

A technology of rotating machinery and vibration signals, which is applied to instruments, measuring devices, and measuring ultrasonic/sonic/infrasonic waves, etc. It can solve problems such as inability to sample synchronously, complex circuits, and waveform data intervals, and achieve continuous and uninterrupted collection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

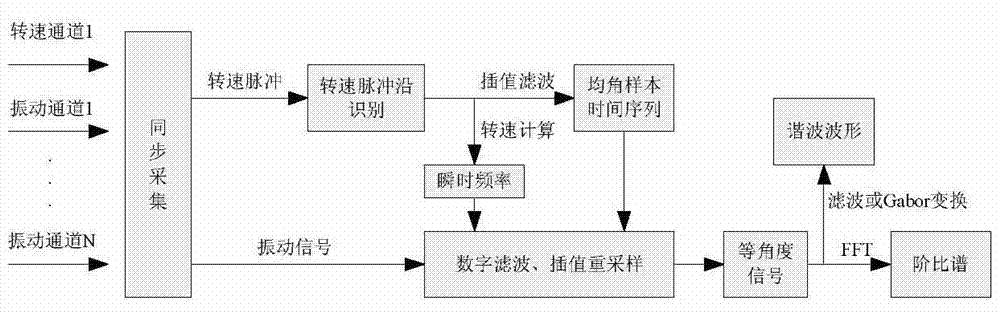

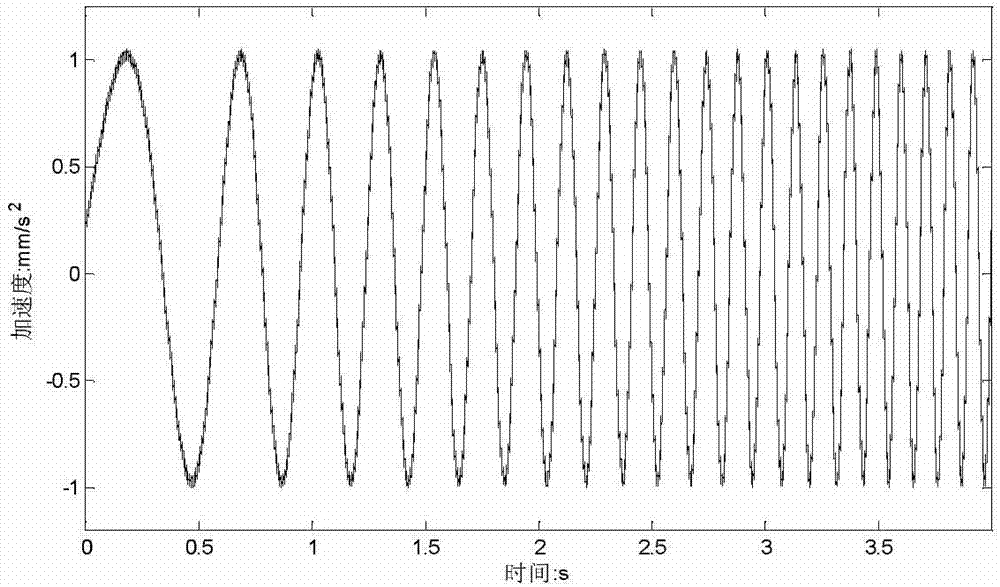

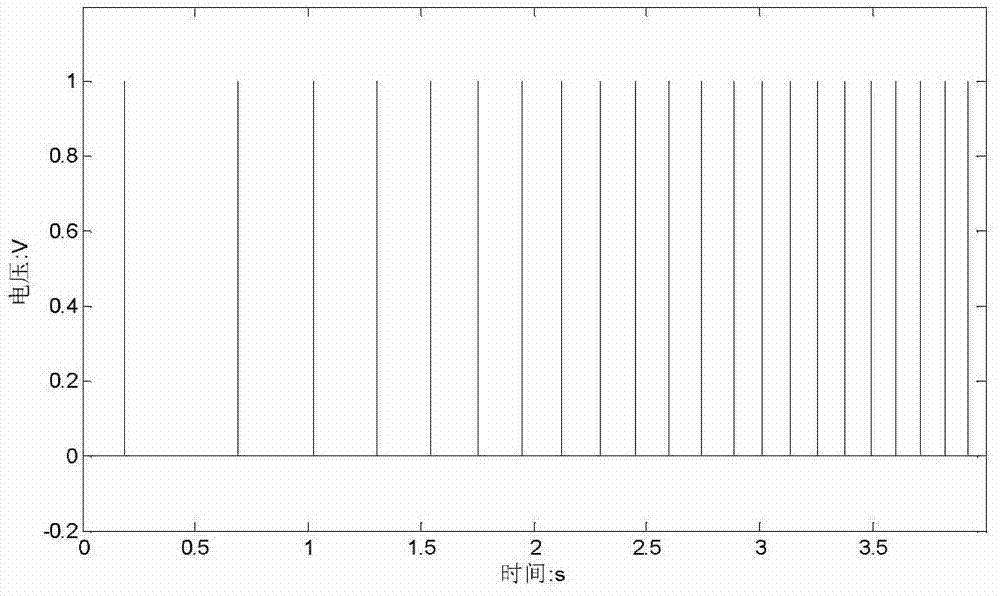

[0026] An embodiment of a method for realizing synchronous order tracking analysis of vibration signals of rotating machinery, see Figure 1 to Figure 8 , the method comprises the steps of synchronously collecting the vibration signal of the rotating machinery and the key-phase pulse signal occurring once in one revolution by using a fixed sampling frequency, selecting a vibration order ratio M, and using an interpolation filter to interpolate the key-phase pulse by 2×M times to obtain The time series of equal-angle signal samples, and then perform low-pass filtering and interpolation re-sampling on the vibration signal to obtain the equal-angle vibration sampling signal. After processing the equal-angle vibration sampling signal, the vibration order ratio spectrum and harmonic waveforms of each order are finally obtained. ; The specific steps are:

[0027] 1) Continuously and synchronously collect rotating machinery vibration signals and speed key phase pulse signals with a f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com