Complete alternation synchronous sampling and analyzing method for rotating machinery vibration signals

A technology of rotating machinery and vibration signals, applied in the testing of machines/structural components, instruments, measuring devices, etc., can solve the problems of order ratio analysis error, inaccurate sampling data, asynchrony, etc., to save hardware, reduce costs, Reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

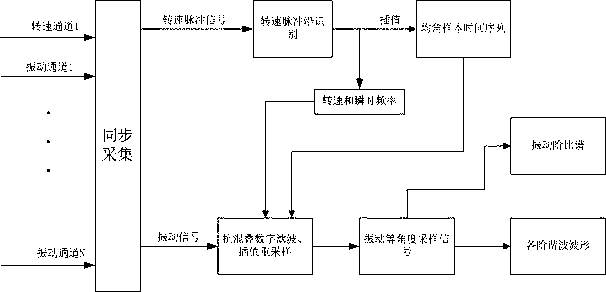

[0034] refer to figure 1 As shown, the whole cycle synchronous sampling and analysis method of the rotating machinery vibration signal of the present invention includes:

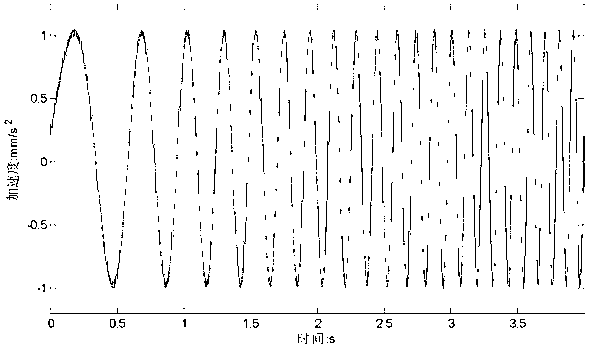

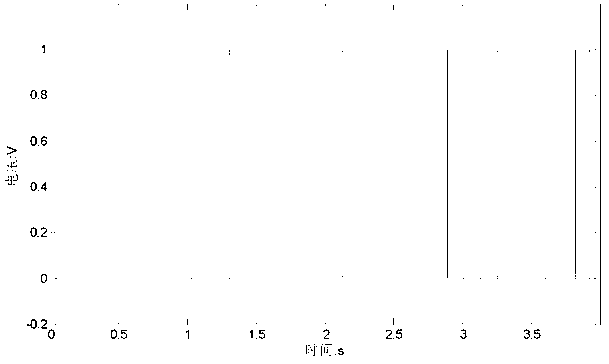

[0035] Step 1: Continuously and synchronously collect the vibration signal and the key phase pulse signal at a fixed sampling frequency, and the key phase pulse signal is generated once every revolution of the rotating machine;

[0036] Step 2: According to the key-phase pulse signal, obtain the rotational speed and instantaneous frequency of the rotating machinery per revolution;

[0037] Step 3: Select a vibration order ratio M, and use the interpolation filter to interpolate the key-phase pulse signal by 2×vibration order ratio M times to obtain the average angle sample time series;

[0038] Step 4: Perform anti-aliasing digital filtering and interpolation resampli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com