Super concentrated hotpot seasoning type food forming machine

A hot pot bottom material and forming machine technology, which is applied in food forming, food science, application, etc., to achieve the effects of ensuring product quality, improving production efficiency, and uniform specifications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

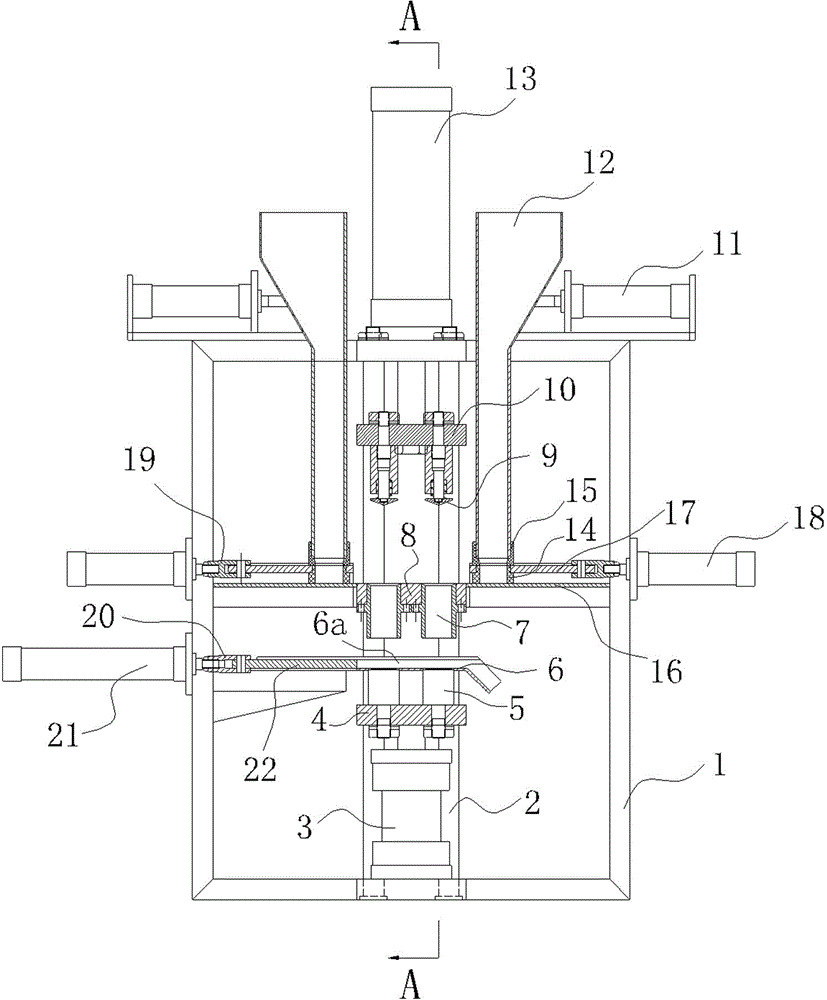

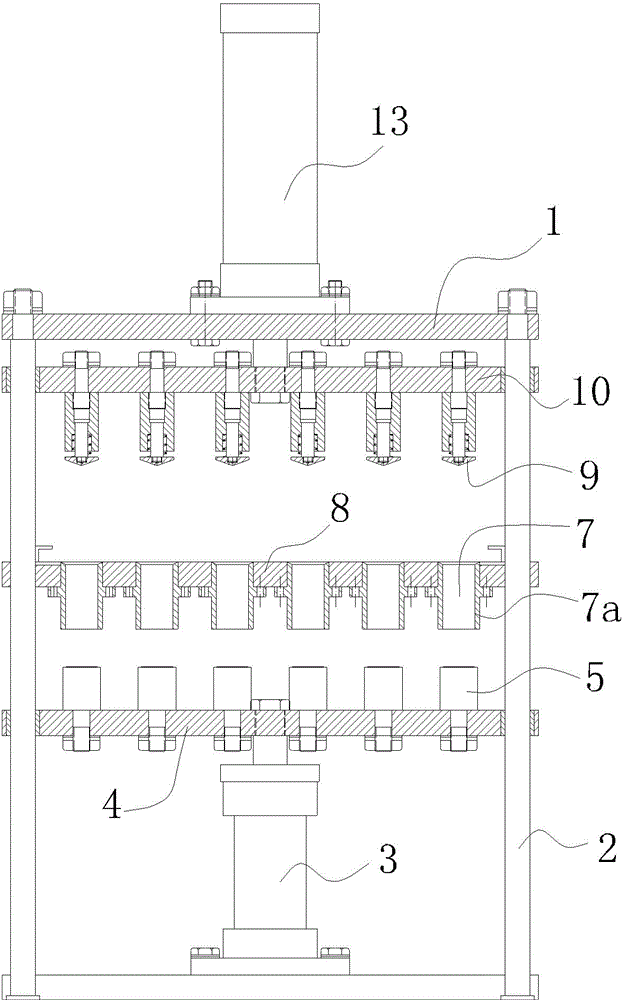

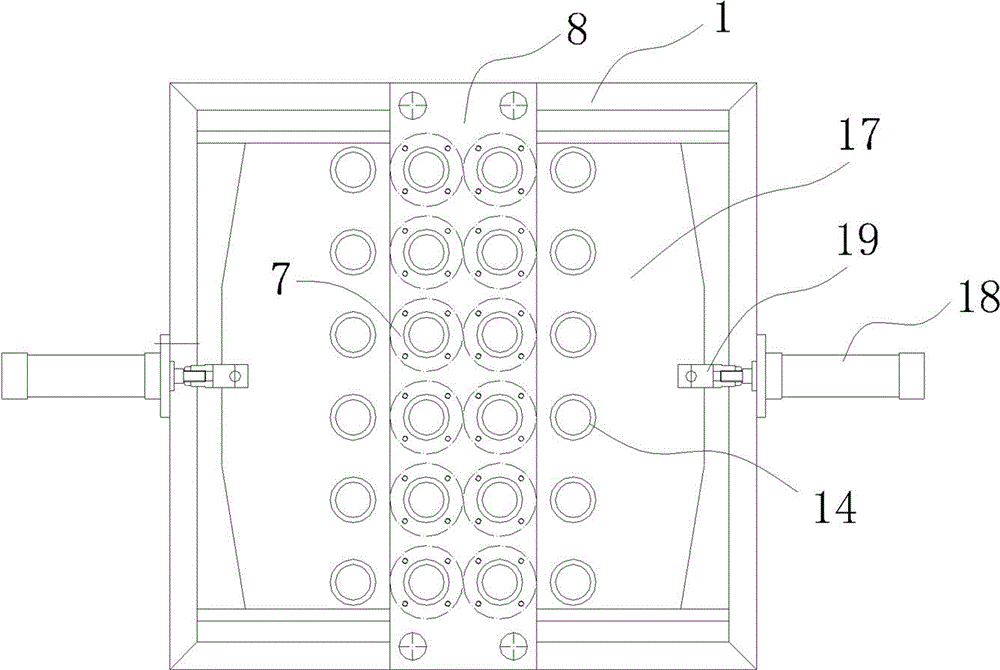

Method used

Image

Examples

Embodiment Construction

[0034] In order to facilitate a clear and complete description of the embodiments of the present invention, the following relevant terms are briefly described first:

[0035] Super-concentrated hot pot base: It is a hot pot base developed and produced by the applicant company on the basis of traditional hot pot base. The main ingredients are vegetable oil, fine chili noodles, Pixian watercress, fermented soybean powder, vegetable protein powder, and ginger , garlic, spices, essential oils, food spices, etc., are produced and formed into blocks by using slag-free technology. The ratio of adding water is 10-25 times, so it is called super-concentrated hot pot bottom material. After the super-concentrated hot pot bottom material is boiled with water to form hot pot soup, there is no spice residue in the soup.

[0036] Measuring cylinder: To measure the volume of powdery materials, to ensure that the weight of each compressed hot pot bottom material is within the allowable measur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com