Cross Lapper

A cross-lapper and deflecting roller technology, applied in the direction of rolling mechanism, textile and papermaking, fiber processing, etc., can solve the problem of not having an independent cover tape, and achieve the effect of avoiding interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

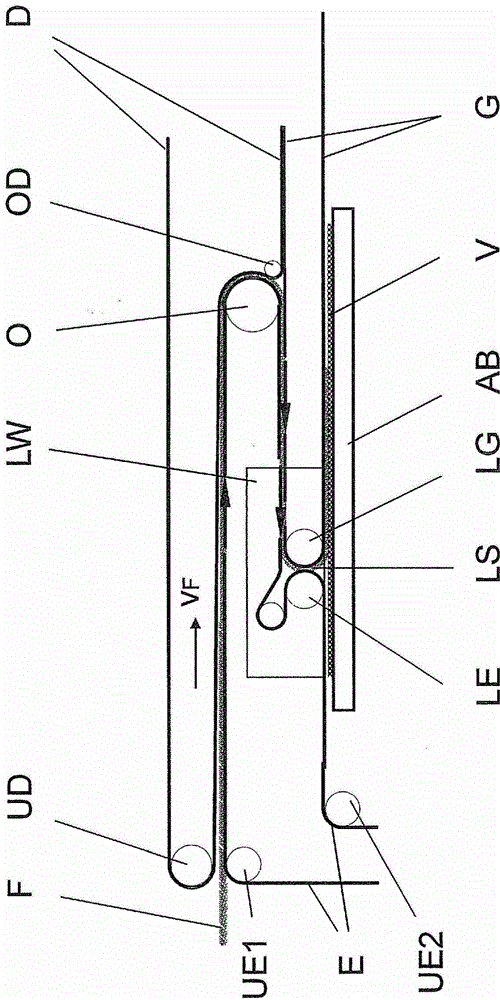

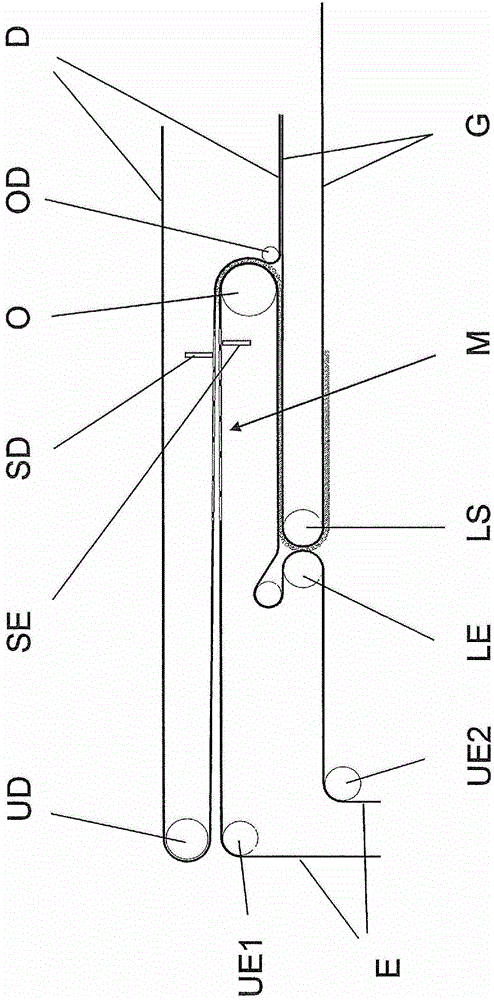

[0034] The pile F is conveyed on an endless endless feed belt E to a crosslapper, only the main components of which are shown in the figure. The direction of travel of the pile F and the feed belt E is indicated by arrows. The pile F moves at a speed vF at which the feed belt E circulates. The feed belt E is tensioned and guided around deflection rollers UE1 , UE2 and also around a first deflection roller O which is arranged in a carriage OW (not shown in detail) in connection with the upper The carriage OW performs periodic reciprocating motion together.

[0035] Above the feed belt E, the cover belt D runs at the same speed and in the opposite direction of rotation. In the area of the tuft feed, the cover web D is guided around the deflection roller UD and runs substantially parallel to the feed belt E (or at an acute angle relative to it) towards the first deflection roller O of the upper carriage OW. On the way between the deflection roll UD and the deflection roll O,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com