Coaxiality measurer of mounting hole of cylinder cover fuel injector and inner circle of baseplate seam allowance

A technology for installing holes and fuel injectors, applied in measuring devices, mechanical measuring devices, instruments, etc., can solve problems such as difficulties, high costs, and complicated measurement processes, and achieve the effects of improving measurement efficiency, ensuring product quality, and accurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

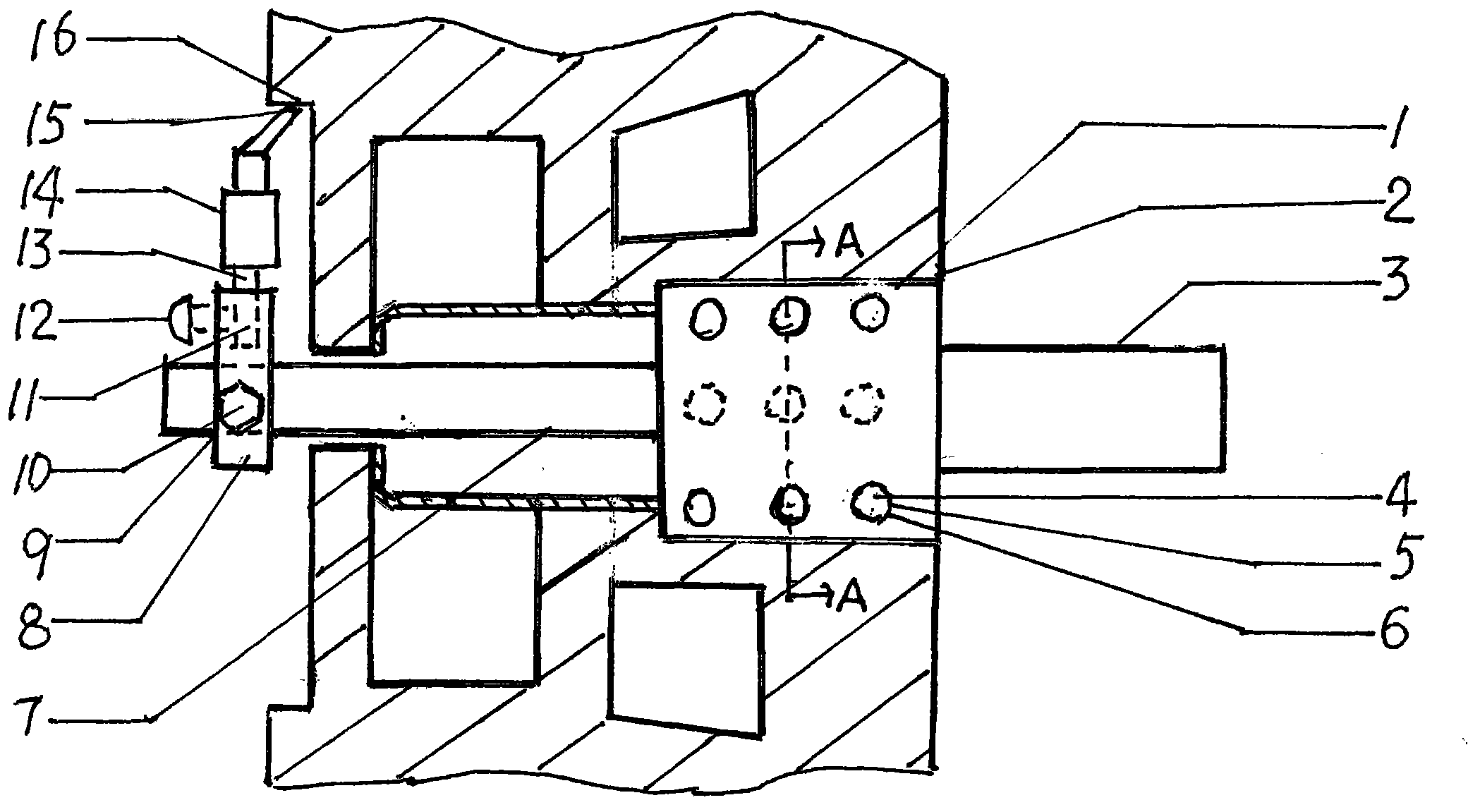

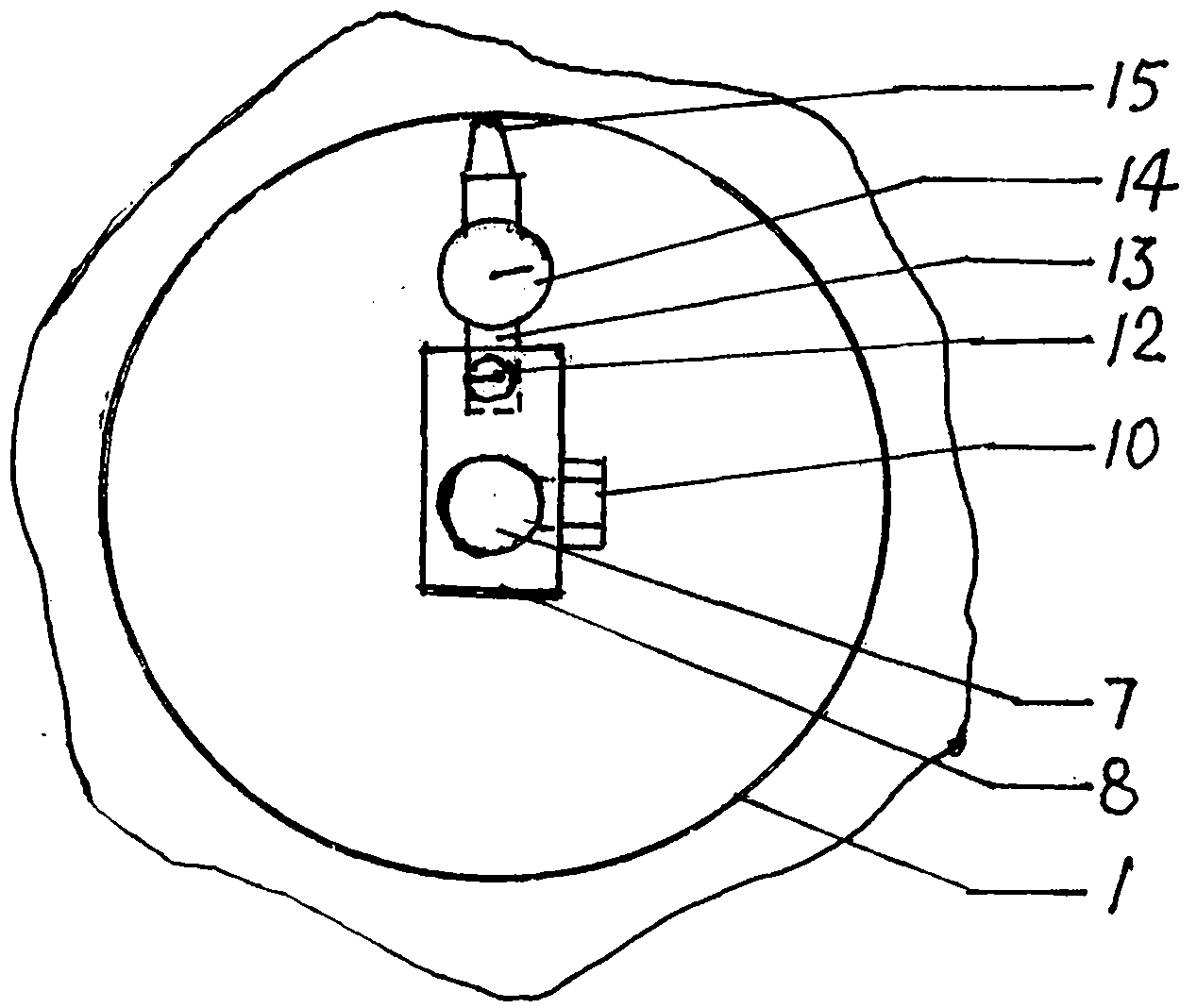

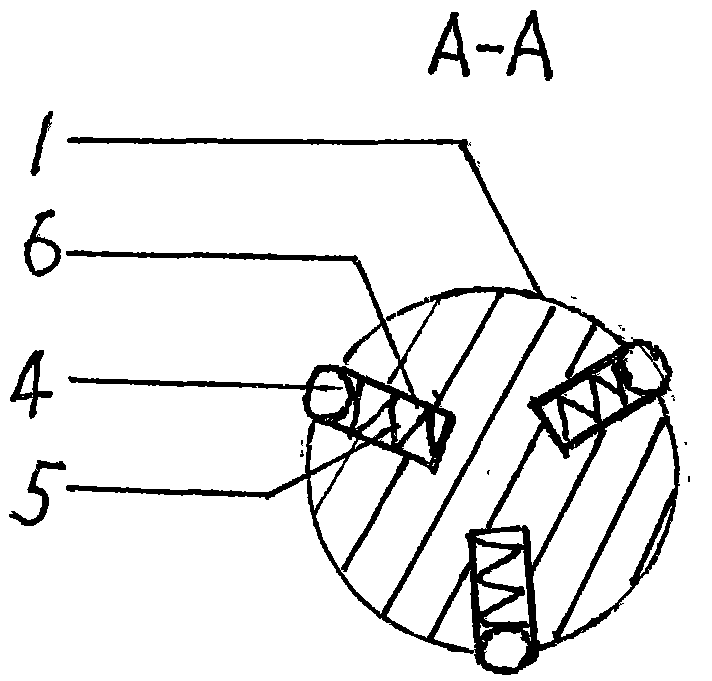

[0012] The accompanying drawing is a structural diagram of the measuring device for the coaxiality of the inner circle of the workpiece 16V280 cylinder head fuel injector mounting hole to the bottom plate seam. See attached figure 1 , 2 , 3, the expandable mandrel (1) left end is provided with the front rod (7) that diameter is Φ 20 millimeters, and the right end is provided with the handle (3) that diameter is 30 millimeters and is 60 millimeters long; Expandable mandrel (1 ) is Φ69.000 mm in diameter, and the inner diameter of the cylinder head injector mounting hole (2) is Φ70.000 mm; the expandable mandrel (1) is inserted in the cylinder head injector mounting hole (2), and the expandable Three expansion beads mounting holes (6) with an inner diameter of Φ4.50mm distributed in an equilateral triangle in the horizontal direction of the type mandrel (1), and three rows of uniformly distributed longitudinal diameters of the expandable mandrel (1) are Φ4. 00 mm expansion bal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com