A load distribution optimization method for cooperative operation of two cranes

A load distribution and optimization method technology, which is applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as broken arms, uneven load distribution, and inability to fully guarantee the safety of hoisting operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

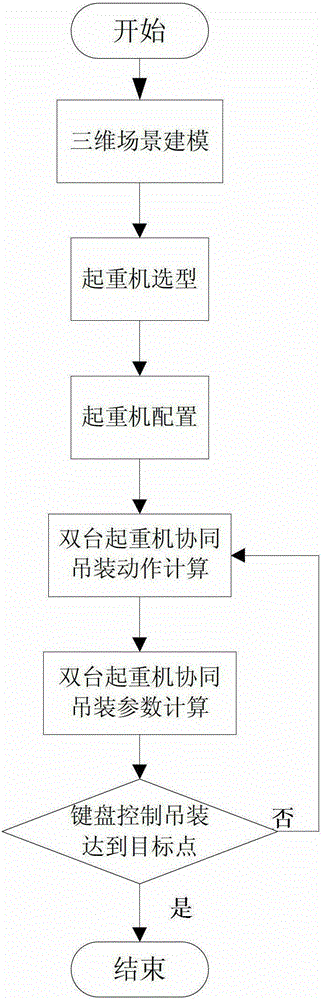

[0063] Such as figure 1 As shown, the method steps of an embodiment of the present invention are as follows:

[0064] Step 1: 3D scene modeling;

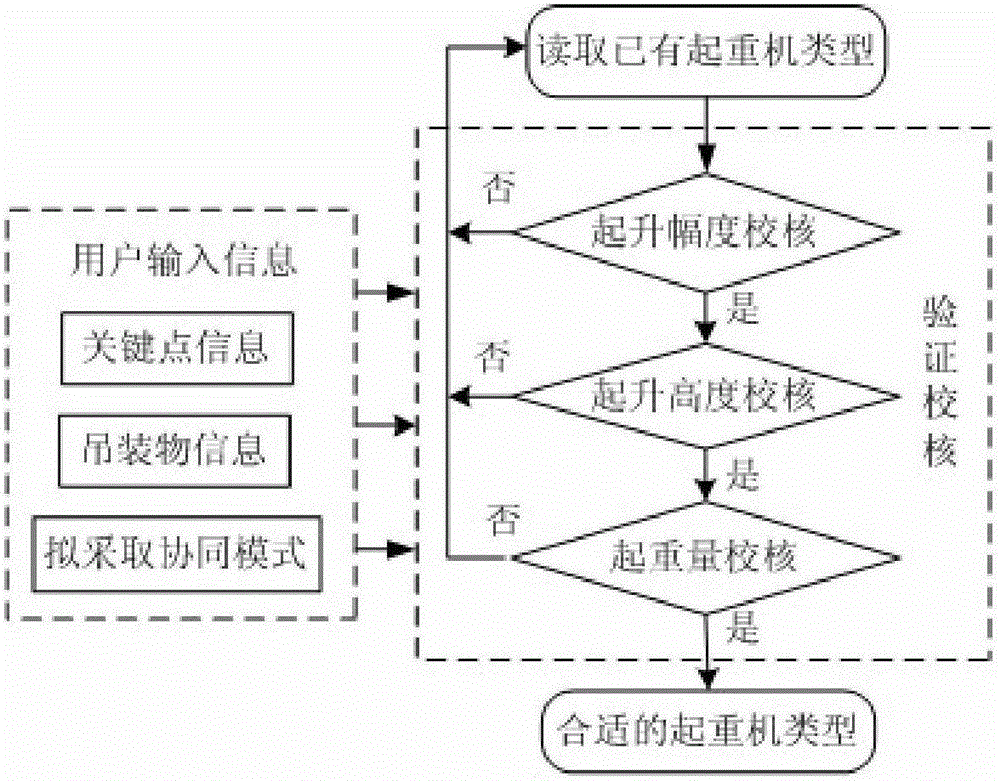

[0065] Step 2: Crane selection;

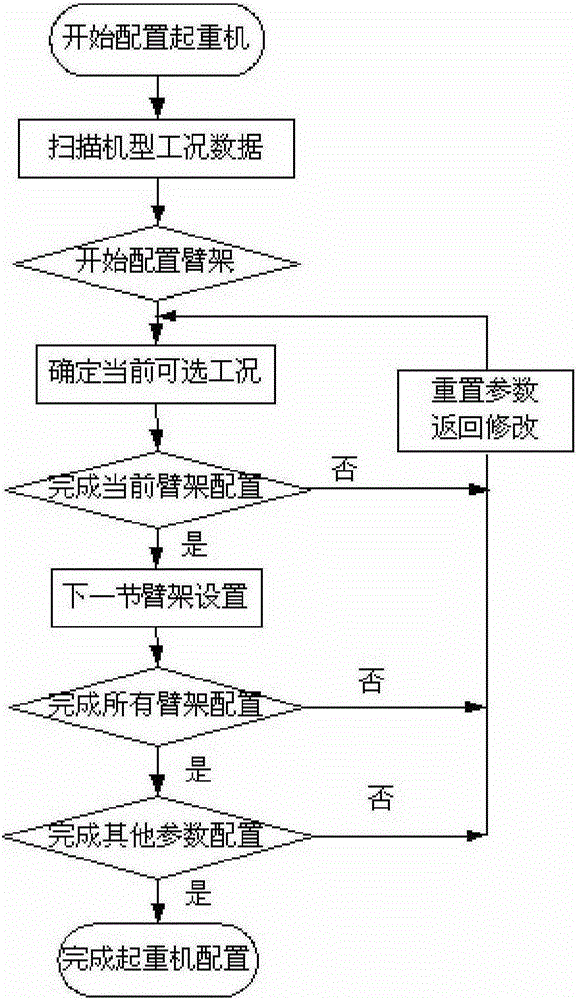

[0066] Step 3: Crane configuration;

[0067] Step 4: Calculation of the coordinated hoisting action of the two cranes;

[0068] Step 5: Calculation of the hoisting parameters of the two cranes;

[0069] Step 6: Optimizing the load distribution of the coordinated hoisting of two cranes;

[0070] Step 7: Reach the hoisting target point;

[0071] Step 8: Hoisting is finished.

[0072] In Step 1, the 3D scene modeling can be divided into two parts: 1) OpenGL provides the basic geometry for drawing; 2) Models with complex shapes need to be imported through third-party software to create model files.

[0073] The first part includes five basic geometric bodies: cuboid, cylinder, cone, torus, and sphere. We only need to provide the corresponding parameter input interface and interaction means, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com