Spline gear cold extrusion one-step molding device

A forming device and spline technology, applied in the direction of metal extrusion dies, etc., can solve the problems of inability to guarantee strength and precision, increase production costs, etc., and achieve the effect of improving production efficiency and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

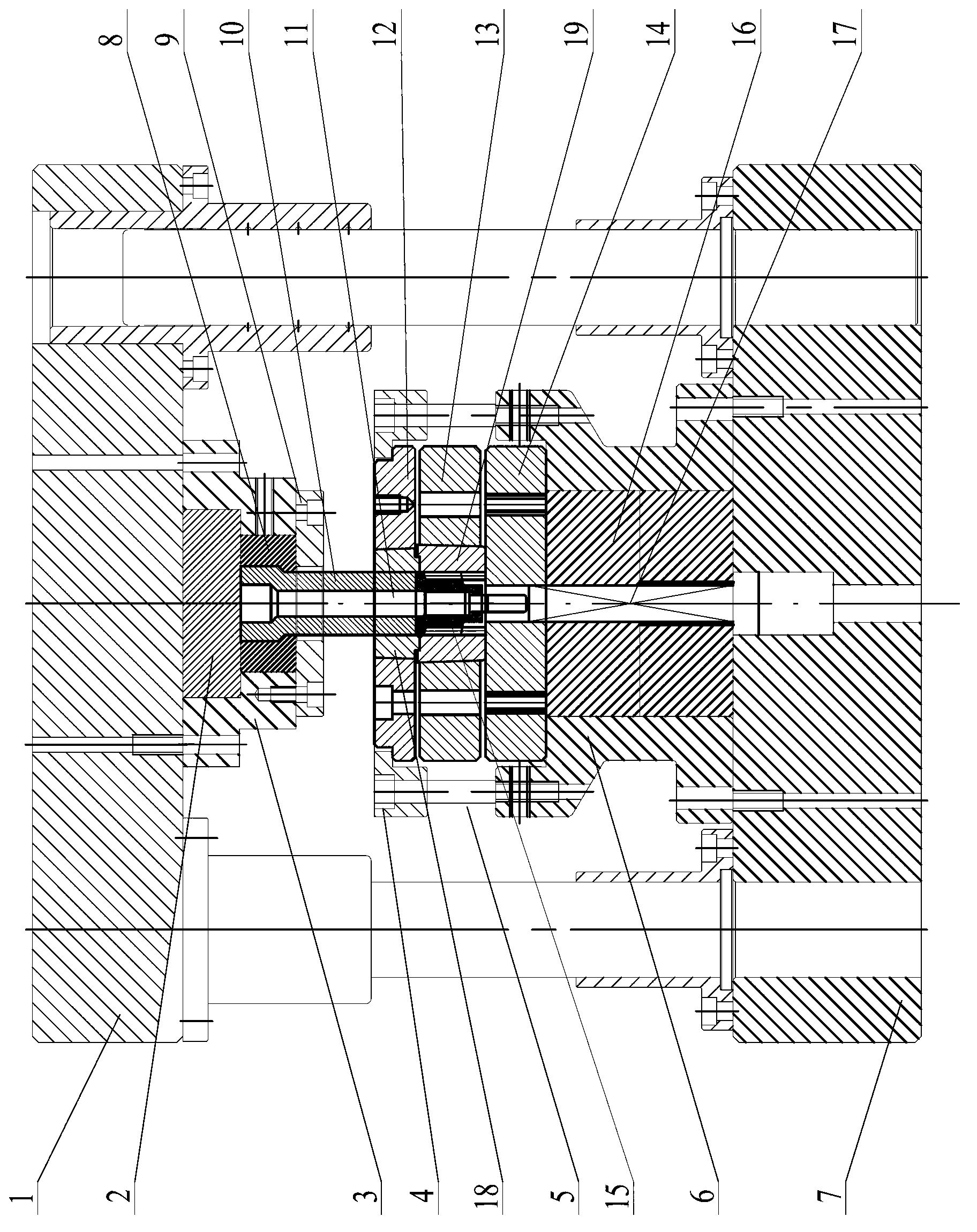

[0012] The present invention will be further described below in conjunction with specific drawings and embodiments.

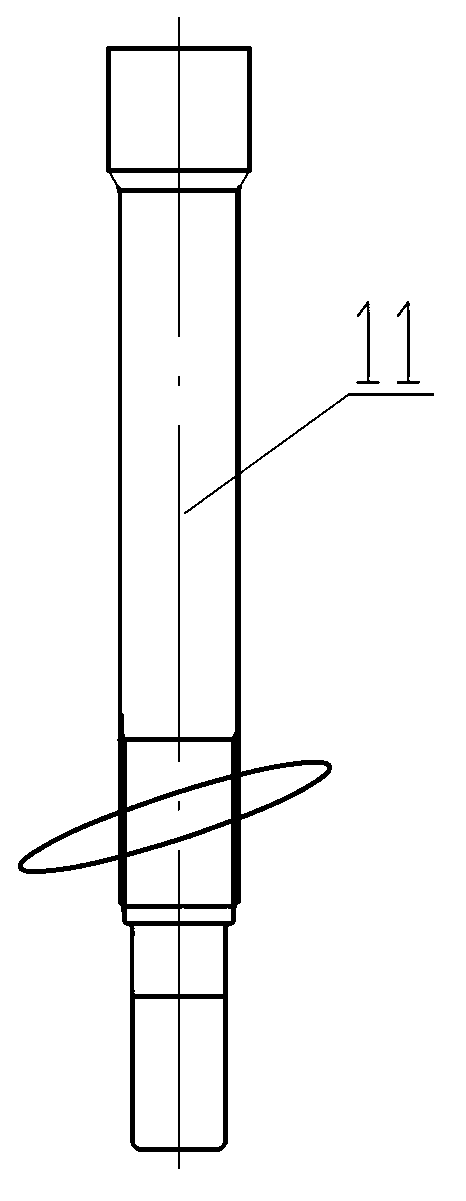

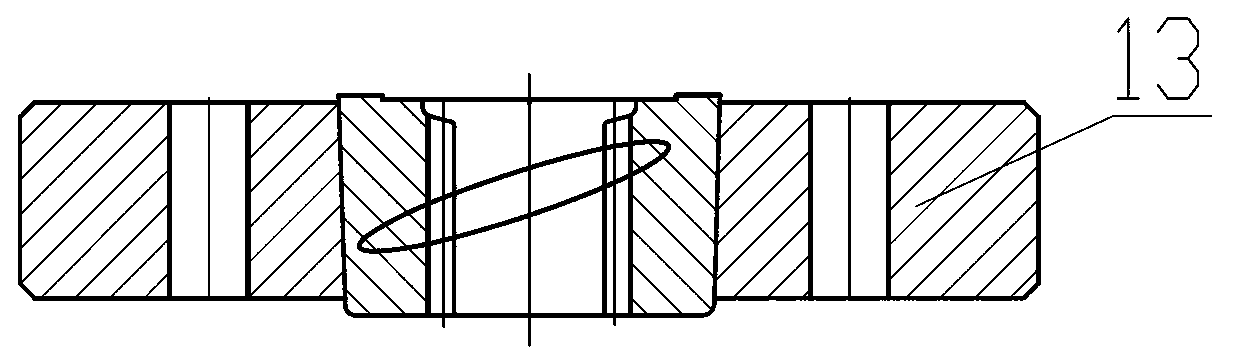

[0013] As shown in the figure: the splined gear cold extrusion primary molding device includes an upper mold base 1 and a lower mold base 7, an upper mold base 3 is fixed on the lower surface of the upper mold base 1, and an upper mold base 3 is fixed on the lower surface of the upper mold base 3. The upper platen 9 is fixed, the punch holder 8 is arranged in the upper mold base 3, and the punch guide sleeve 10 is arranged in the punch holder 8; The lower mold base 6 is fixed on the upper surface of the lower mold base 6, and a pad 14 is provided on the lower mold base 6; a spline punch 11 is provided in the punch guide sleeve 10; a core plate is provided on the upper surface of the pad 14 13. A mold core 19 is provided in the mold core plate 13, a cover formwork 12 is provided on the upper surface of the mold core plate 13, a cover mold core 18 is provided in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com