Underwater specialized low-temperature resistant and high-pressure resistant intelligent self-suction type injection pump

A jet pump and self-priming technology, which is applied in the field of underwater special low-temperature and high-pressure resistant intelligent self-priming jet pumps, can solve problems such as low intelligence, affecting work, and current cannot be adjusted, and achieve a high degree of intelligence , extended service life, simple and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0018] In order to make it easy to understand the technical means, creative features, objectives and effects achieved by the present invention, the present invention will be further explained below in conjunction with specific drawings.

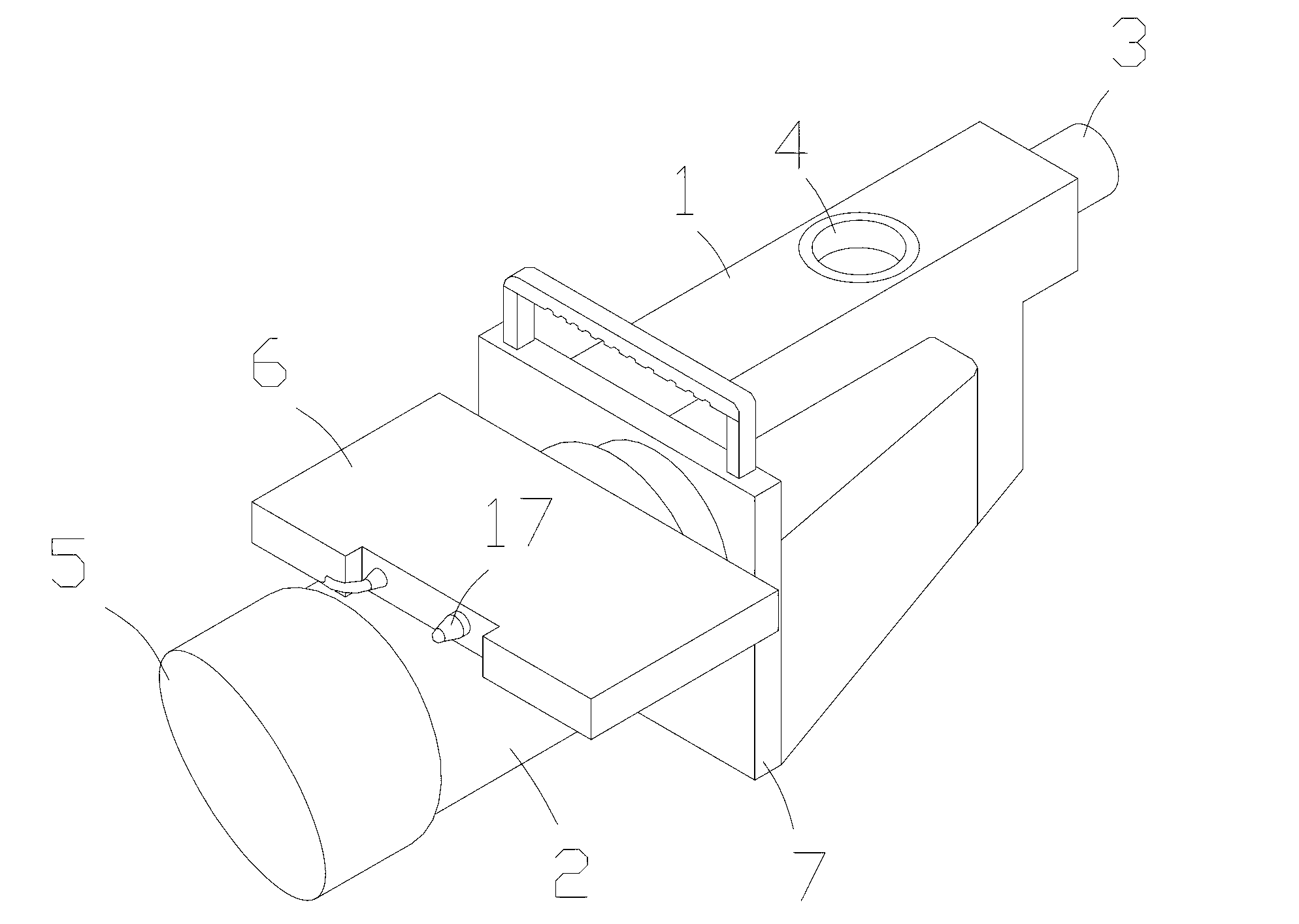

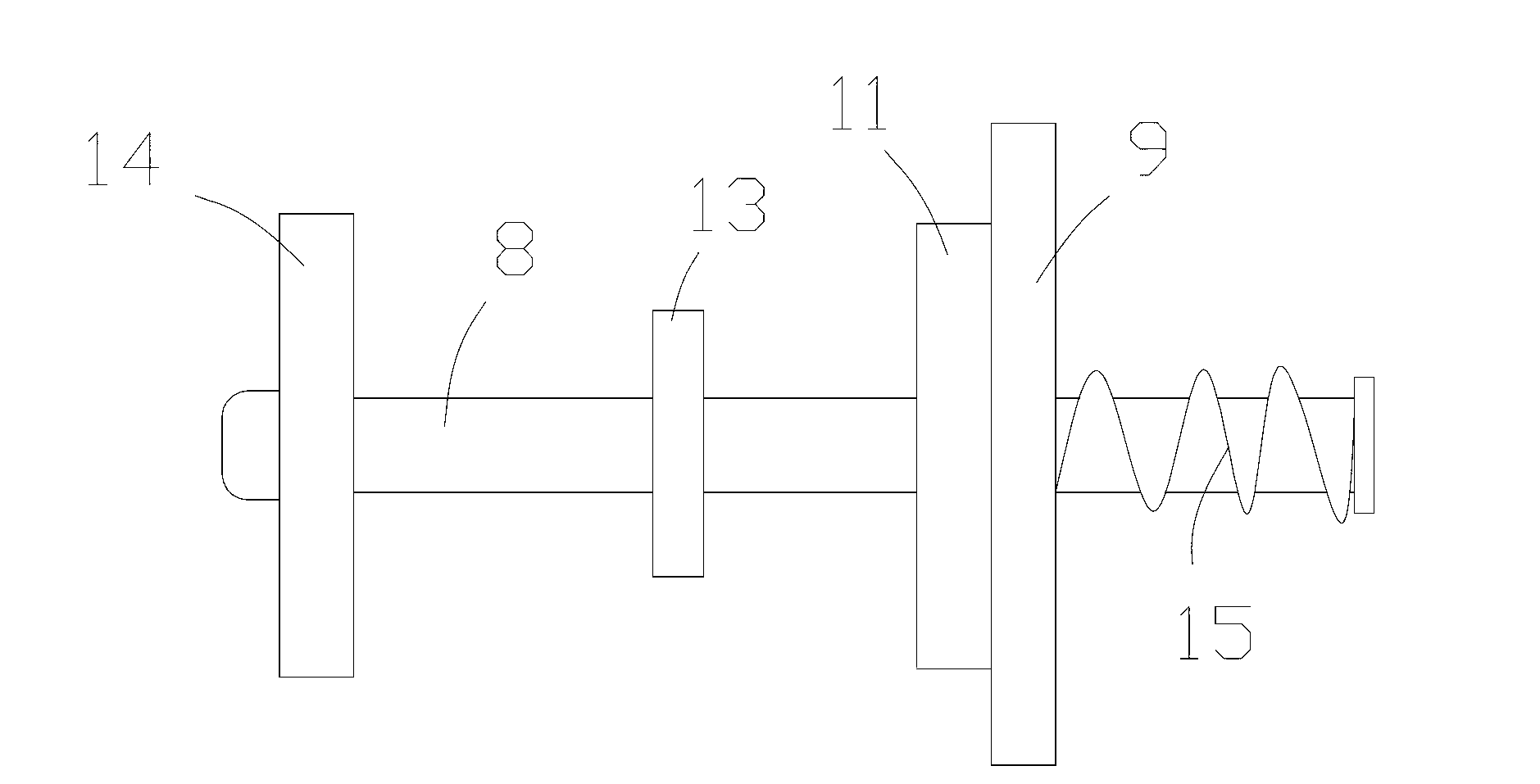

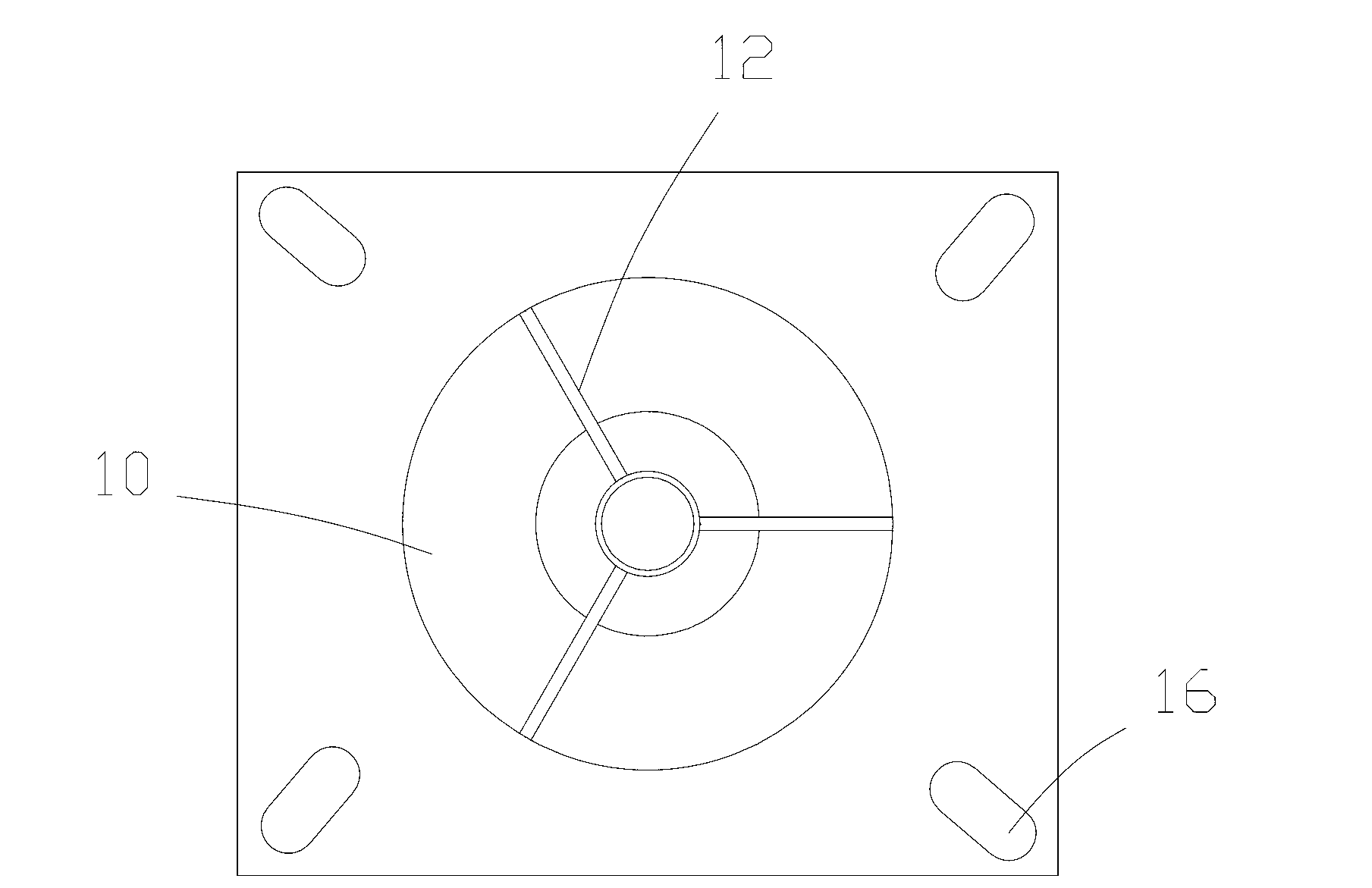

[0019] Such as Figure 1-Figure 4 As shown, an underwater special low-temperature and high-pressure-resistant intelligent self-priming jet pump includes a housing 1 and a double-shaft motor 2 connected to the housing 1. The housing 1 has a water suction cavity and is provided in the water suction cavity. There is an impeller assembly, the front end of the housing 1 is provided with an injection port 3, the upper end of the housing 1 is provided with a water inlet 4, the output shaft of one end of the motor 2 is connected to the impeller assembly, the other end of the motor 2 is connected with an end cover 5, and the end cover 5 and the motor 2 A sealed inner cavity is formed between the inner cavity, and a radiator is arranged in the inner cavit...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap