Zinc-manganese dry battery with improved structure

A zinc-manganese dry battery and zinc cylinder technology, which is applied in the field of dry batteries, can solve the problems of battery capacity decline, easy aging, and shortened discharge time, and achieve improved firmness and safety, strong adhesion and acid resistance, and capacity decline rate Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

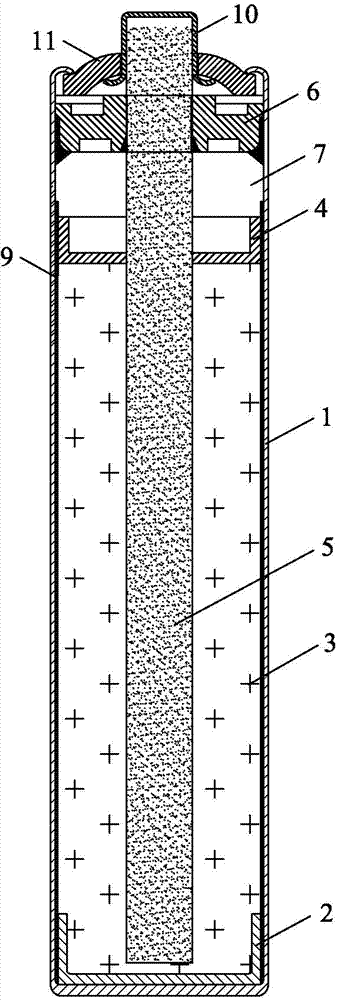

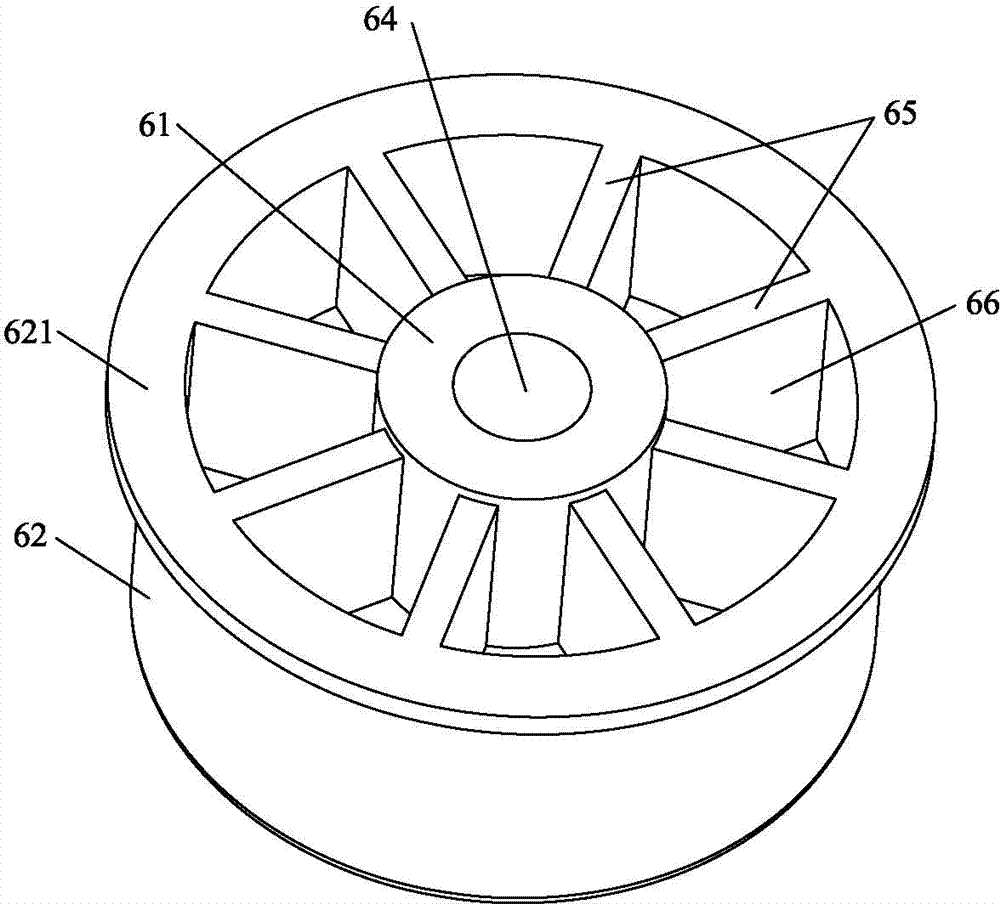

[0040] like Figure 1 to Figure 3 It shows that a structurally improved zinc -manganese dried battery in this embodiment includes zinc cylinder 1. Polycin paper 9, base 2, isolation tablets, carbon rods 5, sealing unit, positive hat 10 and block cover 11Paper 9 is set up between the positive pole material 3 and the zinc cylinder 1, which is set on the surface of the positive pole material 3, which is inserted in the middle of the positive pole material 3 and and the central part of the positive pole material 3 and the part of the positive pole material 3 and the part of the positive pole material 3 and the part of the positive pole material 3 and the part of the positive pole material 3 and the central part of the positive pole material 3, andPass through the isolation piece 4, the sealing unit is set on the exposed end of the carbon rod 5 and seal the opening end of the zinc tube 1, which is the end of the positive hat 10 to the end of the carbon rod 5.The ministry is also located...

Embodiment 2

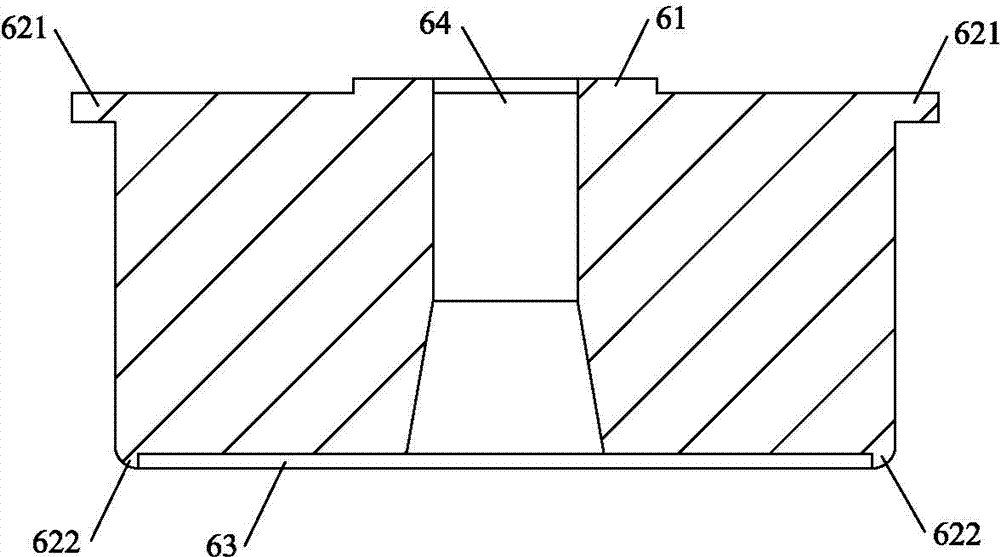

[0048] like Figure 4 The difference between the embodiments and the embodiment one is that the outer grooves 8 inwardly depressed in the interior of the zinc cylinder 1 and the conversion 621 connection in the embodiments of this embodiment.The groove 8 on the surface of the zinc tube 1 causes the internal protruding structure of the zinc cylinder 1. When the sealing ring 6 kale is put into the zinc cylinder 1, the convex 621 is closely fitted with the protruding structure, which can better improve the sealing ring.6 sealing and sealing, and the raised structure has a better positioning effect on the sealing ring 6 on the Links 621.

[0049] The other structure of this embodiment is the same as the embodiments, and I won't go into details here.

Embodiment 3

[0051] The preparation process of an embodiment -one structural improved zinc -manganese dry battery, which includes the following process steps:

[0052] A. Pull the zinc chip processing into a zinc tube at one end;

[0053] B. Fix the opening of the zinc tube 1 in the step A, and press the base of the base 2 through the opening to the bottom of the zinc tube 1;

[0054] C. Put the inner wall of the zinc cylinder 1 in step B. Passion -layer paper 9;

[0055] D. Fill in the positive electrode material 3 in the zinc cylinder 1 in step C, and the depth of the compression depth of the positive electrode material 3 is 13 ~ 15mm;

[0056] E. Pay isolation tablets 4 in the upper surface of the positive pole material 3 in step D;

[0057] f. Pass the carbon rod 5 through the isolation tablet 4 in the step E and insert it into the positive electrode material 3;

[0058] G. Plugs at the outer peripheral 62 and the lower end of the sealing circle 6 and the lower end of the hole 64;

[0059]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com