Method for three-stage pressure filling skid car in natural gas mother station

A technology of natural gas and parent station, applied in the direction of container filling method, equipment loaded into pressure vessel, gas/liquid distribution and storage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

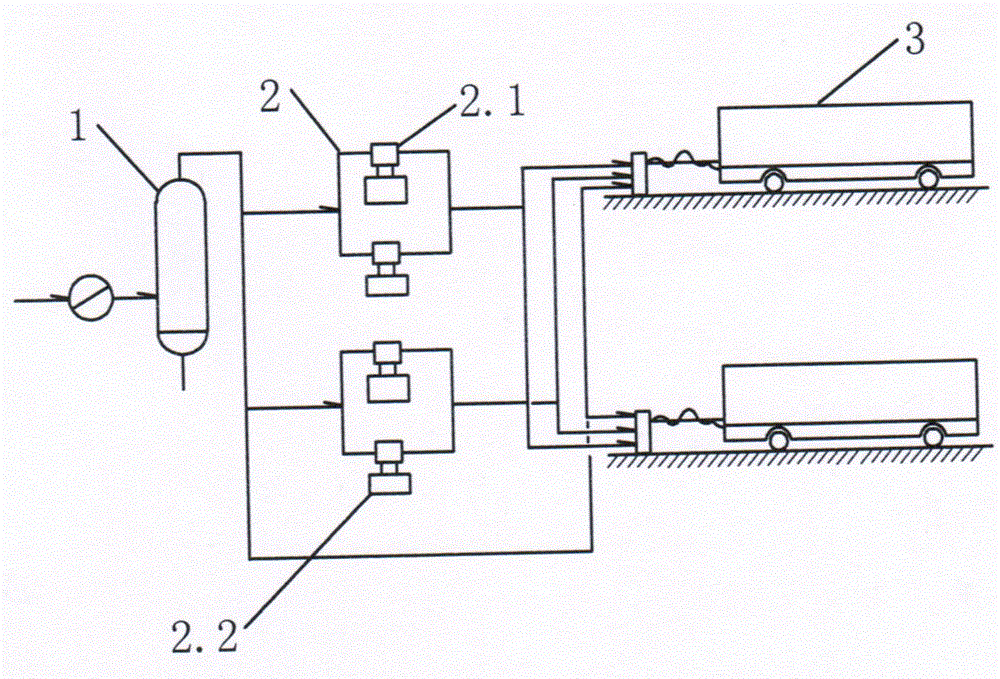

[0012] According to the picture:

[0013] The natural gas source is transported from the external network through the delivery pipe to the dehydration tank 1 of the natural gas mother station, and the dehydration tank of the natural gas mother station is connected to the charging machine 2 through a pipeline.

[0014] 1. The first level of filling: the skid car 3 is filled under the condition of the external network pressure of 6PM in the dehydration tank of the natural gas mother station;

[0015] 2. The second stage filling: start the first stage charging machine 2.1, and fill the skid car 3 with a pressure of 16MP;

[0016] 3. The third stage filling: Start the second stage charging machine 2.2 to fill the skid car 3 with natural gas at a pressure of 25MP until the allowable pressure requirement of the skid car is reached.

[0017] Features:

[0018] The use of three-stage pressure for natural gas filling of the skid car, and equal pressure filling can save energy, reduce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com