Two-stage pressure segmentation sequential filling method for container filling by compressed natural gas station

A technology for compressing natural gas, natural gas, applied in container filling methods, equipment loaded into pressure vessels, gas/liquid distribution and storage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

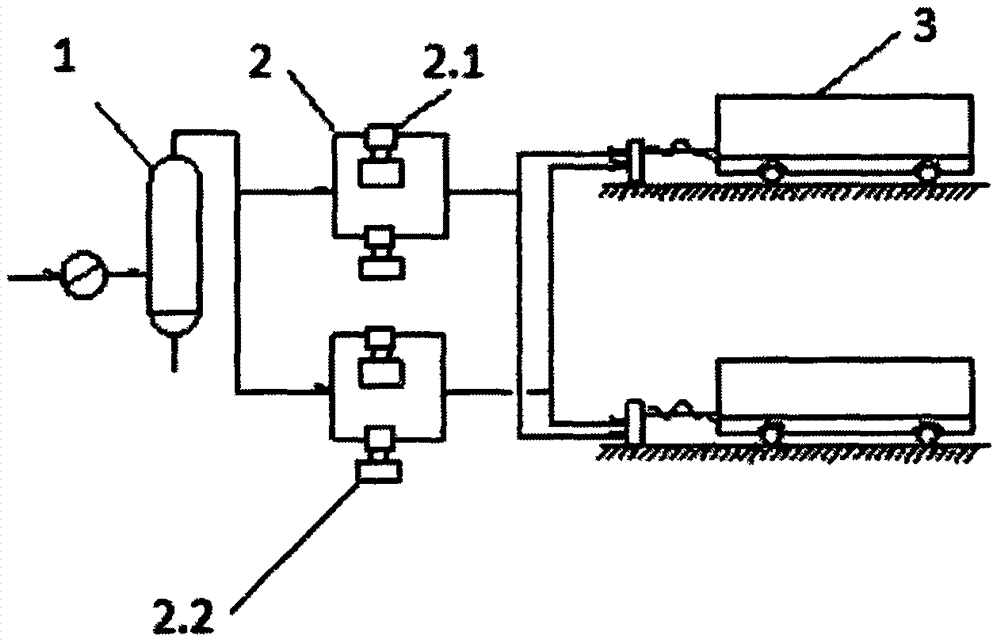

[0011] According to the picture:

[0012] The natural gas source is transported from the external network to the dehydration tank 1 of the natural gas station through the delivery pipe, and then communicated with the pressurizers 2.1 and 2.2 respectively.

[0013] 1. Filling in the first stage: start the first stage charging machine 2.1, and fill the container 3 with a lower pressure;

[0014] 2. Filling in the second stage: Start the second stage charging machine 2.2 to fill the container 3 with natural gas at high pressure until the required pressure is reached.

[0015] Features:

[0016] Using high and low pressure two-stage compressed natural gas to fill the container sequentially in stages, compared with continuous high-pressure consistent filling, it can save power consumption, reduce investment and operating costs.

[0017] The method of the invention can simultaneously fill multiple containers with compressed natural gas, thereby improving work efficiency.

[0018]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com