Direction straightening-out mechanism of cylinder bundling machine

A horizontal direction and material sorting technology, applied in pyrotechnics, offensive equipment, weapon types, etc., can solve problems such as low production efficiency, inapplicability, and inconsistency, and achieve the effect of improving production efficiency and production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

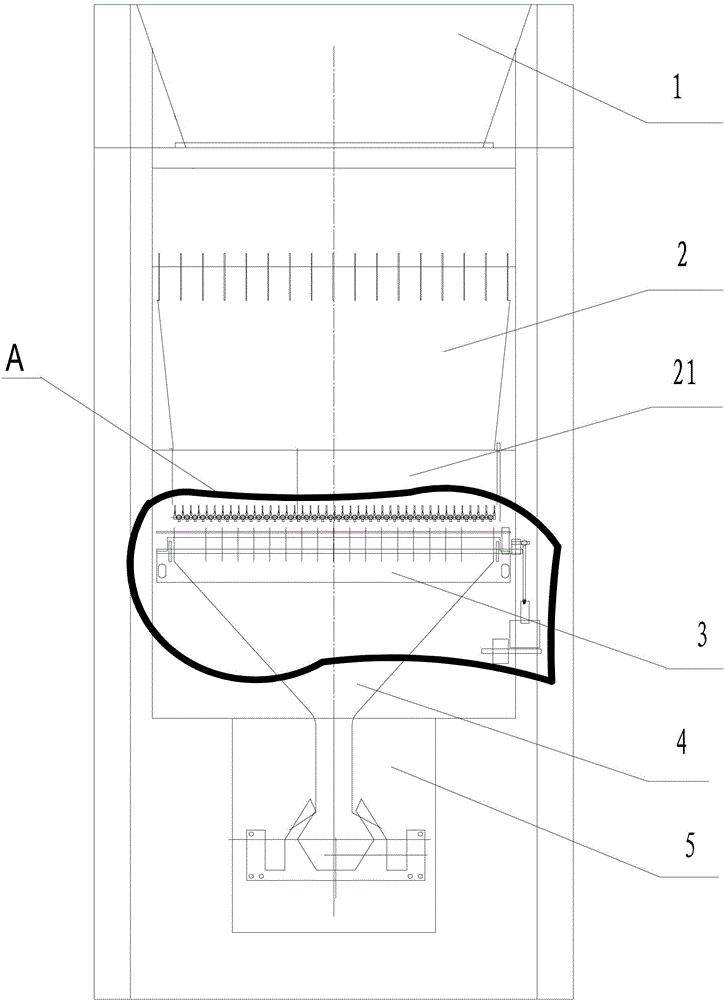

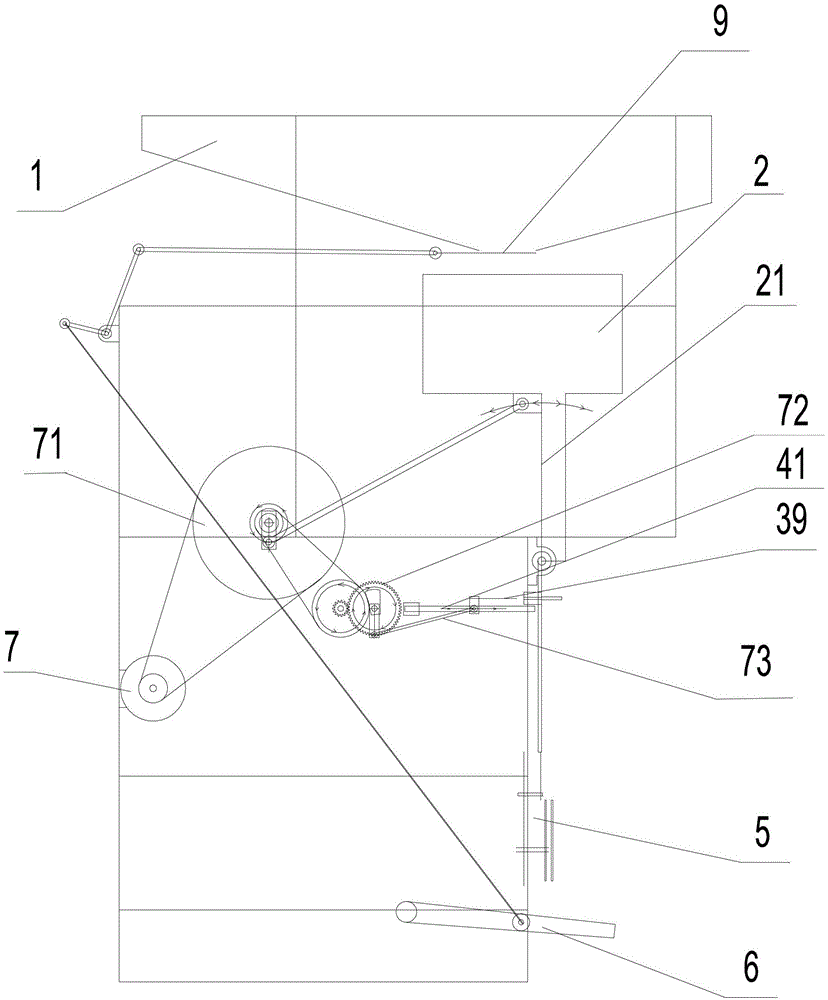

[0018] Referring to the accompanying drawings, a specific structure of the present invention is reflected. The bundling machine includes a storage hopper 1, a sorting hopper 2, a direction straightening mechanism 3, a collecting mechanism 4, and a forming mechanism 5 from top to bottom. A blanking gate 9 is set between the storage hopper 1 and the sorting hopper 2, and is controlled by the blanking pedal switch 6. The drive motor 7 drives the sorting hopper 2 to swing and vibrate through the belt pulley and the crank-link mechanism, and arranges the fireworks tubes 8 into a parallel and neatly arranged state and piles them up in the unloading channel 21 of the sorting hopper 2 .

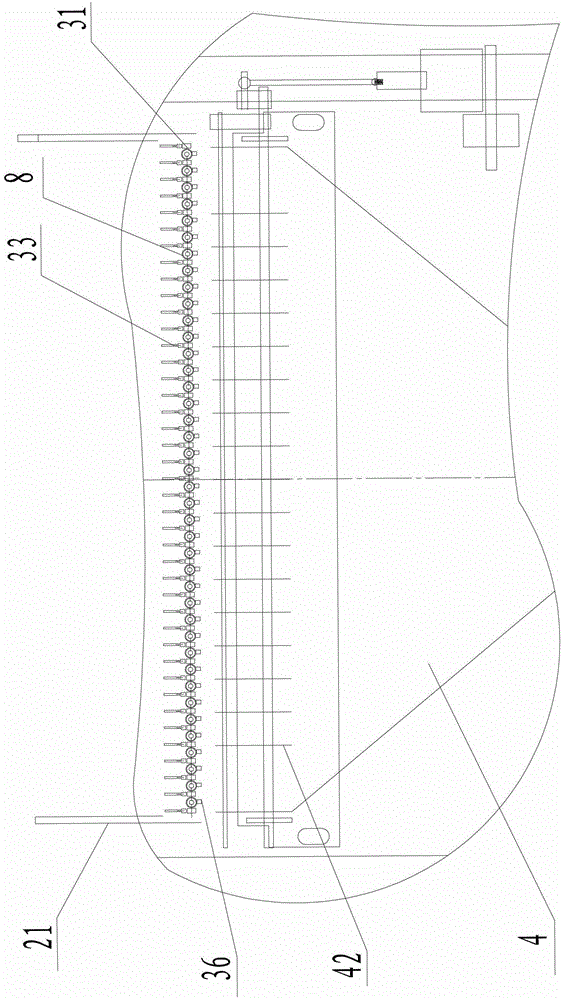

[0019] The direction straightening mechanism 3 includes a number of working slots 31 arranged parallel and juxtaposed in the horizontal direction. The width and height of the working slots 31 correspond to the fireworks tube 8 , that is, only one fireworks tube 8 can be accommodated in each working s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com