Injection device and method for micro-injection molding machine with differential transmission

A technology of differential transmission and injection device, applied in the field of injection device of micro injection molding machine, can solve the problems of unfavorable development and commercial application of micro injection molding machine, high cost, complex structure, etc. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

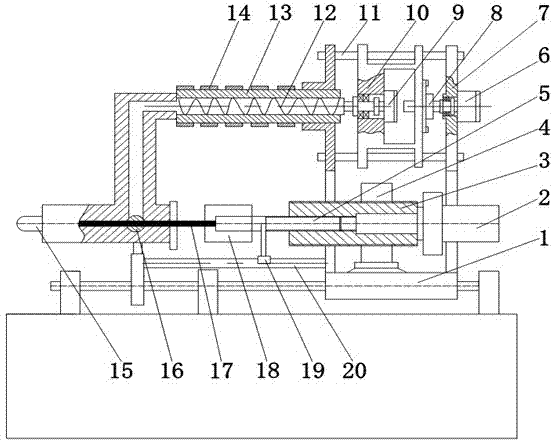

Embodiment Construction

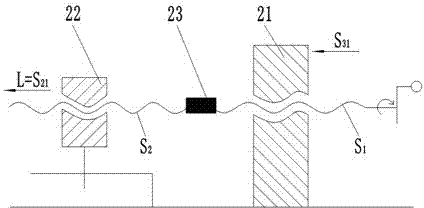

[0017] The working principle of the differential screw drive of the present invention is as follows: figure 2 As shown, the screw rod 23 is made up of threads with two different pitches on the left and right, wherein the right thread rotates in the fixed nut 21; the left thread rotates in the moving nut 22 that can only move but cannot rotate; The pitches are S 1 and S 2 , their threads are in the same direction, both are right-hand threads. When screw 3 turns (rad) angle, the distance that the screw should move to the frame (that is, the fixed nut 21) , while the nut 22 moves to the right relative to the screw for a distance , then the moving distance L of the movable nut 22 relative to the frame should be the algebraic sum of the two moving amounts, namely , because S 1 and S 2 The difference is small, even if If the angle is large, the moving distance L will be small, and the differential thread realizes the precise transmission of the micro-motion device.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com