Glass wiping device

A glass wiper and shell technology, applied in cleaning equipment, home appliances, applications, etc., can solve the problems of long cleaning cycle, high risk, difficult to scrub, etc., to achieve simple structure, good safety, and reduce the risk of falling. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

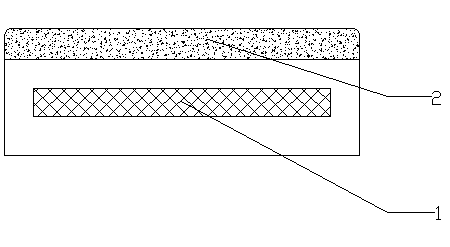

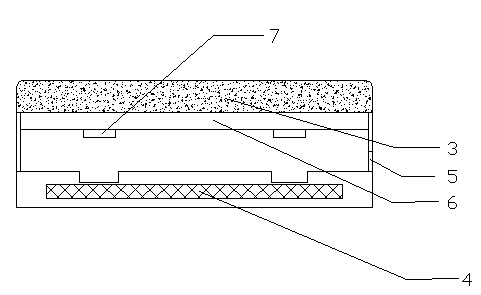

[0022] Such as Figure 1~4 As shown, a glass wiper includes a connecting rod, a wiper A and a wiper B;

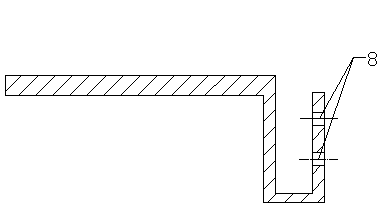

[0023] A connecting plate is arranged on the connecting rod, and a mounting hole 8 is arranged on the connecting block;

[0024] The wiping plate A includes a cleaning head A1, a housing and a magnet block A2, the magnet block A2 is arranged inside the housing A, and the cleaning head A2 is arranged outside the housing A; the wiping board B includes a cleaning head B3, a housing B , iron plate and magnet block B4, the inside of the housing B is provided with a cavity, the iron plate moves in the cavity facing or facing away from the cleaning head B3, and the magnet block is placed outside the cavity away from the cleaning head B3 side; wherein the magnetic force of the magnet block B4 in the wiper B is less than the magnetic force of the magnet block A1 in the wiper A; the wiper B is also provided with an opening 5, and the connecting rod passes through the opening 5 throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com