Six-freedom joint type coordinate measurement machine calibration method

A coordinate measuring machine and calibration method technology, applied in the direction of measuring devices, instruments, etc., can solve the problems of low actual precision of the measuring machine and insufficient sampling density, and achieve the effects of many sampling points, accurate calibration work, and rich postures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

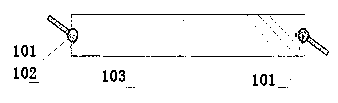

[0014] Taking an articulated coordinate measuring machine as the machine to be calibrated, using a metal rod 103 with cone sockets 102 at both ends as a standard length appliance, placing the metal rod 103 in the measurement space of the machine to be calibrated in different positions and different attitudes; Corresponding to each posture, use the hard probe 101 of the machine to be calibrated to collect point coordinates in the cones 102 at both ends of the metal rod 103, and a length can be obtained for every two points in different cones, and these lengths are used as sampling data The error parameters of the machine to be calibrated are obtained by using the least square method.

[0015] The selected length of the metal rod 103 is 10%-40% of the radius of the measurement space. Two small standard spheres with equal diameters are topped in the conical socket, and the length of the metal rod 103 is defined as the distance between the centers of the two spheres.

[0016]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com