Six-freedom degree articulated flexible COMERO high precision calibration method

A coordinate measuring machine and calibration method technology, applied in the direction of measuring devices, instruments, etc., can solve the problems of large randomness, insufficient sampling density, poor overall machine effect, etc., and achieve the effect of ensuring stability and accurate calibration work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

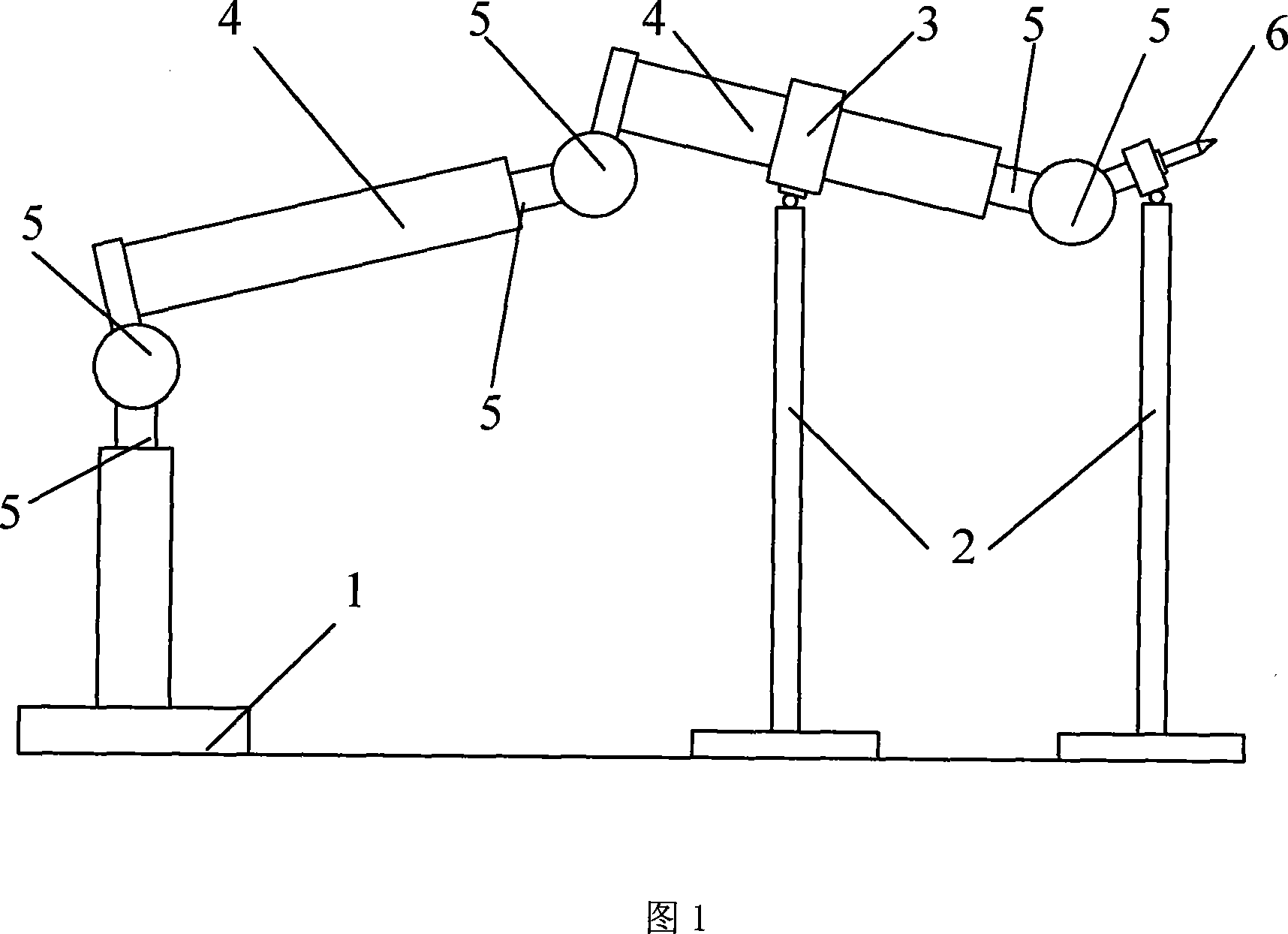

[0024] The machine to be calibrated shown in Figure 1 is a six-degree-of-freedom articulated flexible coordinate measuring machine. On the base 1, two sections of measuring arms 4 are connected in series with six rotatable joints 5 to form an open-chain structure. The end of the open-chain structure is the probe 6 of the measuring machine. Each joint 5 can rotate around its own axis. In order to record the angle of joint rotation, a high-precision circular grating angle sensor is installed on the joint. The attitude of the measuring machine is positioned by the adjustable support rod 2 through the clamp 3 .

[0025] Both theory and practice have shown that for the machine to be calibrated, only when it is calibrated in a relatively large range can it be more reliable in actual use. The principle of least squares performs data processing on the extracted information, so that the error of the whole machine is relatively close to the minimum and maximum errors, and high-precision...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com