Dedusting device for membrane materials

A dust removal device and membrane material technology, applied in the direction of electrostatic cleaning, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of unsustainable use of dust removal, low dust removal efficiency, etc., to achieve both dust removal efficiency and dust removal effect, High dust removal efficiency and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with drawings and embodiments.

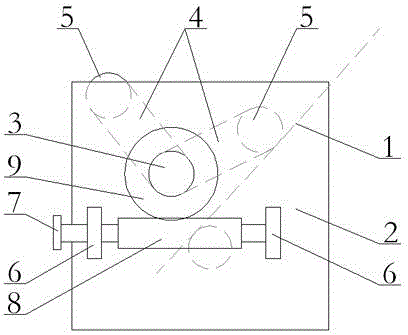

[0013] figure 1 As shown, a film dust removal device includes a frame 2, a rotating shaft 3, a rotating frame 4, a rubber roller 5, a rotating supporting frame 6, a rotating hand wheel 7, a rotating driving worm 8 and a rotating driving worm 9. The rotating shaft 3 is connected to the frame 2, and the two ends of the rotating drive worm 8 are respectively supported on the frame 2 through the rotating support frame 6. The rotating hand wheel 7 is connected to the rotating driving worm 8, and the rotating driving worm wheel 9 is connected to the rotating shaft. On the shaft 3, the rotating drive worm 8 meshes with the rotating driving worm wheel 9, and the rotating shaft 3 is connected to two or more rubber rollers 5 in parallel through the rotating frame 4, and more than two rubber rollers 5 are evenly symmetrical around the axial center of the rotating shaft 3, and the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap