Electromechanical coordinating and restraining method of rotary spindle chattering by utilization of two-shaft tilt sensor

A rotating spindle and sensor technology, applied in the direction of machine/engine, wind engine control, engine, etc., can solve the problems that the wind turbine cannot reach the maximum wind energy capture speed, reduce the wind energy capture efficiency of the wind turbine, and achieve reverse electric braking The torque is smooth and easy to control, the adjustment speed is fast, and the work efficiency is high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

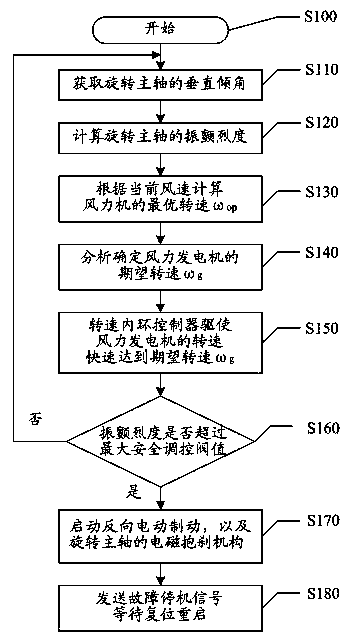

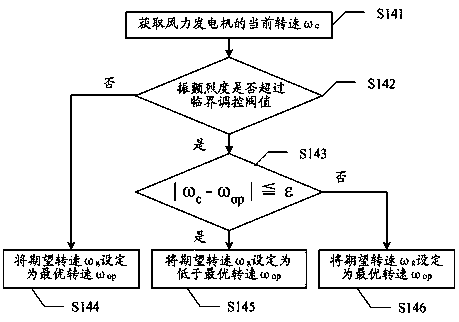

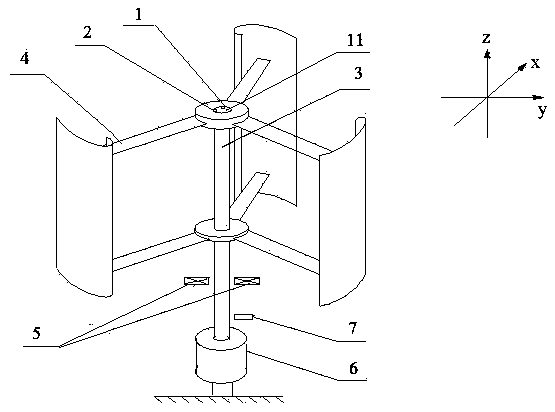

[0053] refer to figure 1 , which is a flow chart of an embodiment of the electromechanical coordination suppression method for vibration of the rotating main shaft of a vertical axis wind turbine according to the present invention. This embodiment comprises the following steps:

[0054] S100, start.

[0055] S110. Obtain the vertical inclination of the rotating main shaft in real time.

[0056] The vertical inclination angle includes the inclination angle value α in the two orthogonal directions in the horizontal section of the main axis x and alpha y . The inclination angle value can be obtained by installing a two-axis inclination sensor on the stationary part at the top of the rotating spindle.

[0057] S120. Calculating the vibration intensity K of the rotating main shaft v .

[0058] The tremor intensity is defined as, K v = α x 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com