Annular-cooler non-pressure water-cooling grating beam

A ring cooler and water cooling technology, applied in the fields of metallurgy and chemical engineering, can solve problems such as unsatisfactory life extension effect, achieve cooling maintenance, avoid strength weakening, and prolong service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0013] The present invention will be further described below in conjunction with the examples, but it is not intended to limit the present invention.

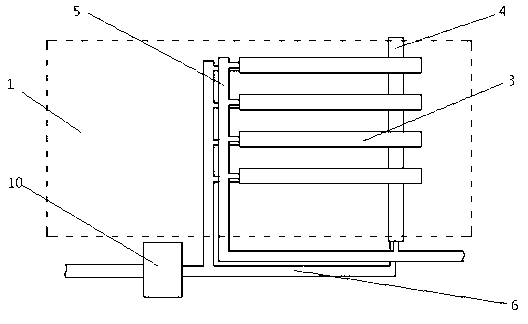

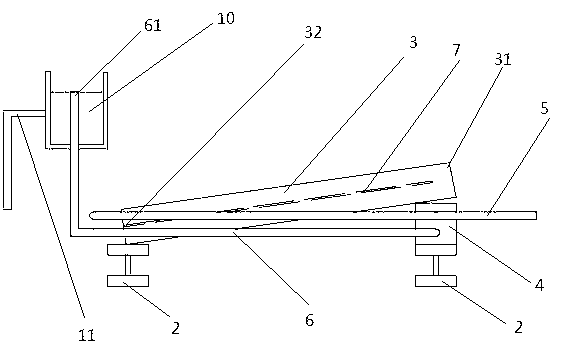

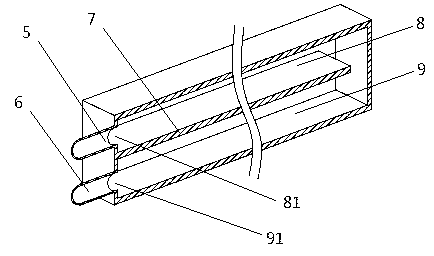

[0014] See figure 1 , figure 2 , the pressureless water-cooled grid beam of the ring cooler includes the support 2, the screen beam 3 and the beam 4 located in the kiln head cover 1, and also includes the water inlet pipe 5 and the water outlet pipe 6, and the screen beam 3 and the beam 4 are at least equipped with Two screen caps, the device is a water-cooled grid beam device, which takes away heat through water flow to achieve cooling effect. The two ends of the beam 4 of the device are arranged on the support 2, the beam 4 and the screen beam 3 are both hollow beams with one end closed, the closed end 31 of the screen beam 3 is arranged on the beam 4, and the other end 32 is arranged on the support 2. , forming a tilted state where one head is high and the other is low. The structure of hollow beam is as image 3 Said, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com