Grinding machine structure provided with movable rotary vertical grinding head

A grinding head and vertical grinding technology, which is used in grinding machine parts, manufacturing tools, grinding/polishing equipment, etc., and can solve the problems of occupation, large space, and large grinding machine volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

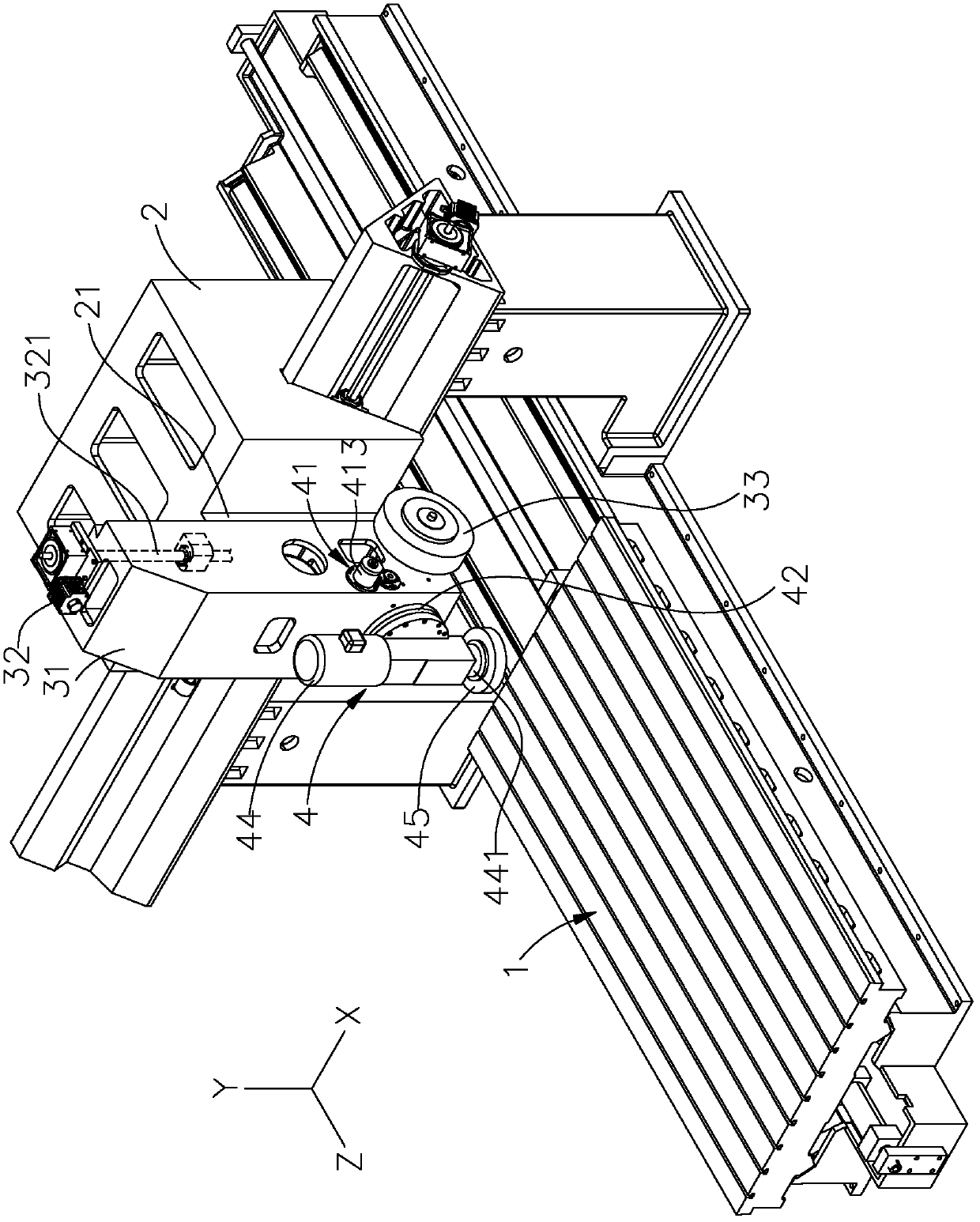

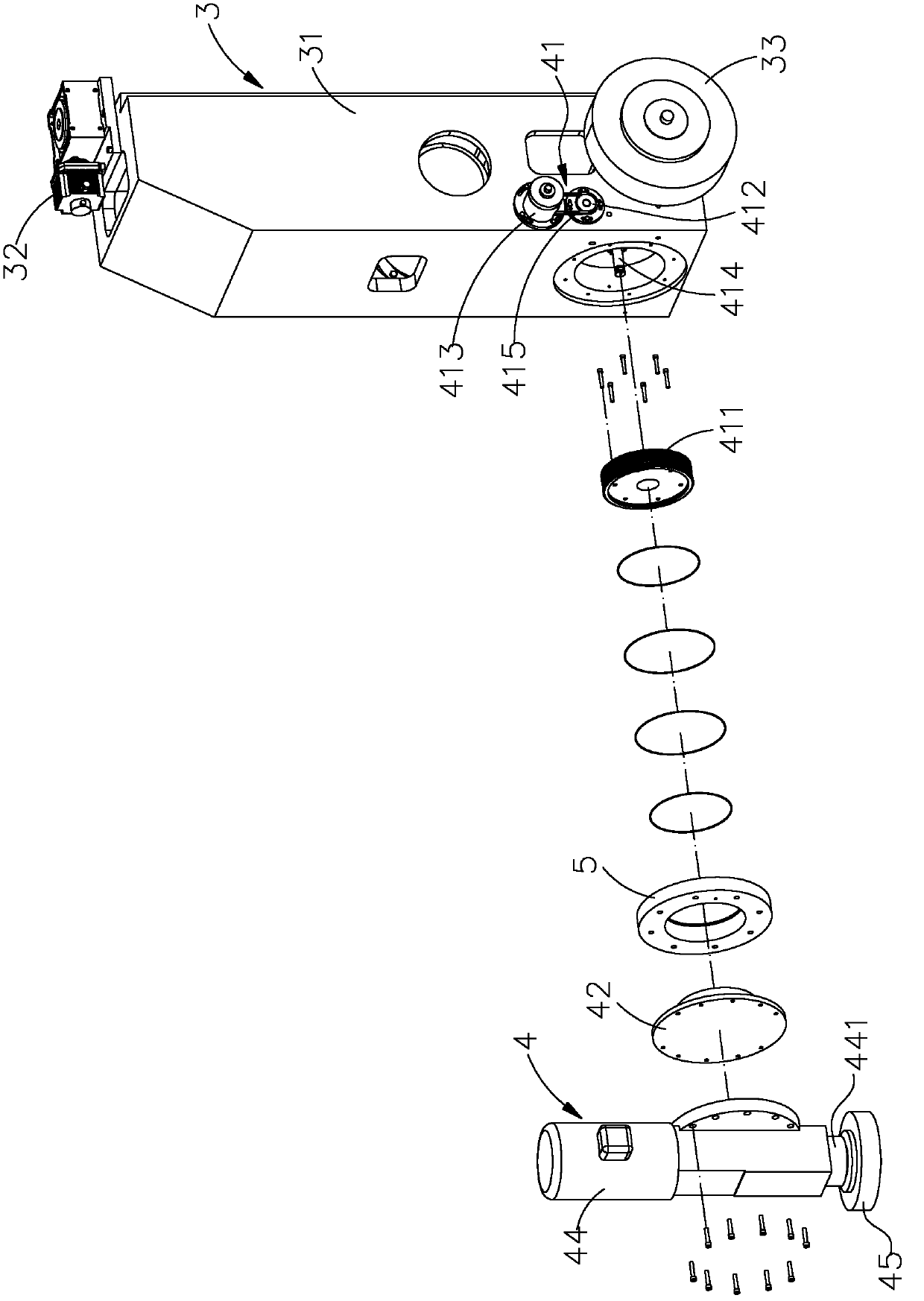

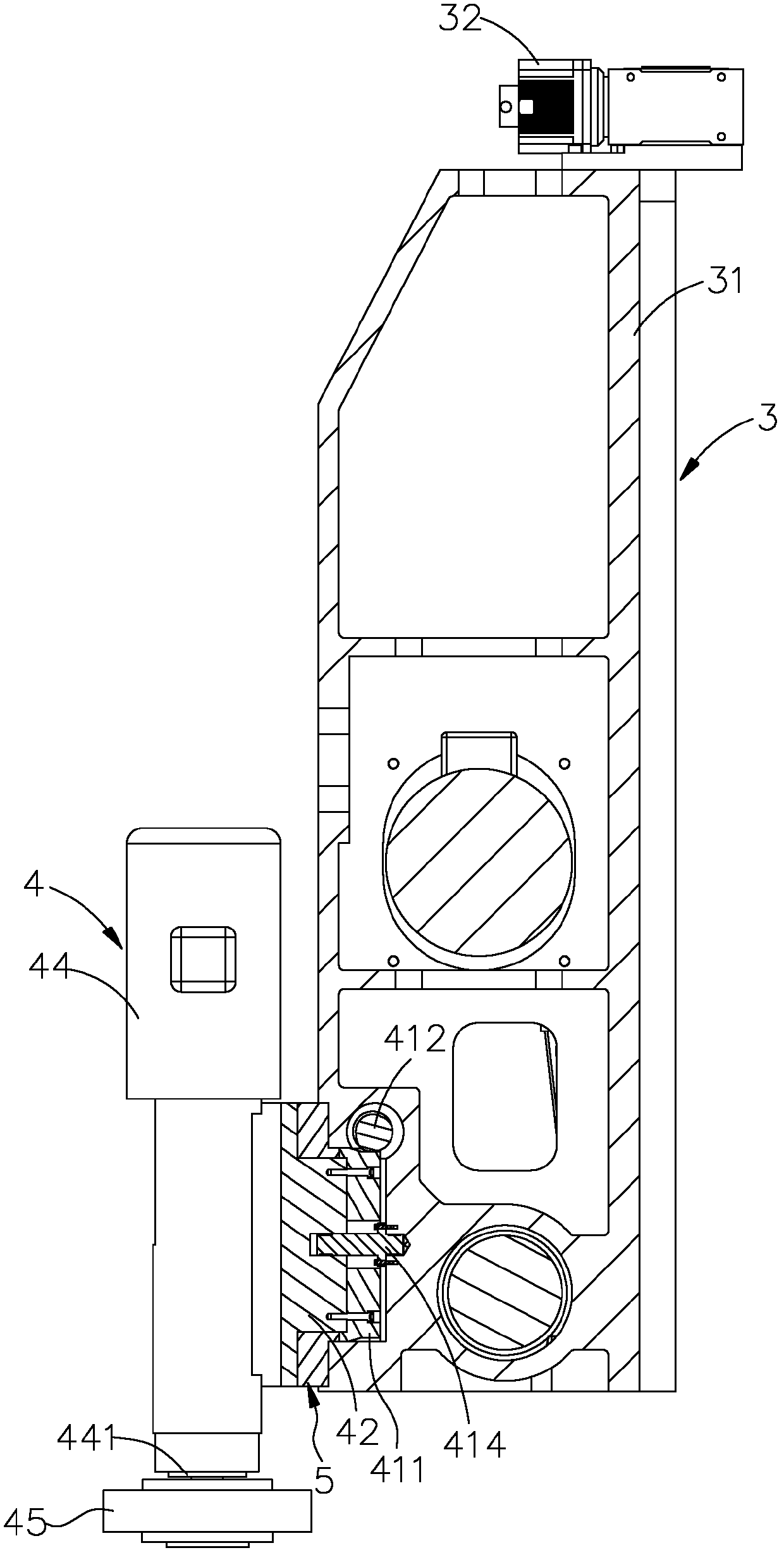

[0035] Such as Figure 1 ~ Figure 4 As shown, the grinding machine structure with movable rotating vertical grinding head provided by the embodiment of the present invention is mainly composed of a body 1, a sliding seat 2, a first grinding head group 3 and a second grinding head group 4, etc. Combination; where:

[0036] The main structure of the body 1 is the same as the existing structure, so I will not repeat it here. The work object can be ground in the X, Y, Z axis and other directions;

[0037] The sliding seat 2 is slidably arranged in the X-axis direction of the body 1, and a sliding groove 21 is formed in the Y-axis direction;

[0038] The first grinding head group 3 is slidably disposed in the sliding groove 21 of the sliding seat 2 by using a housing 31, that is, a guide rail 311 is formed on the housing 31 (as shown in Figures 1 and 4). The guide rail 311 and the sliding groove 21 are combined with each other in a dovetail groove. Therefore, the first grinding head grou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com