Grinding machine structure with vertical grinding head capable of keeping at fixed position and rotating movably

A grinding head and vertical grinding technology, which is applied in the direction of grinding machines, manufacturing tools, grinding/polishing equipment, etc., can solve the problems of insufficient functionality, increasing the overall equipment purchase cost, and increasing the volume of grinding machines.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

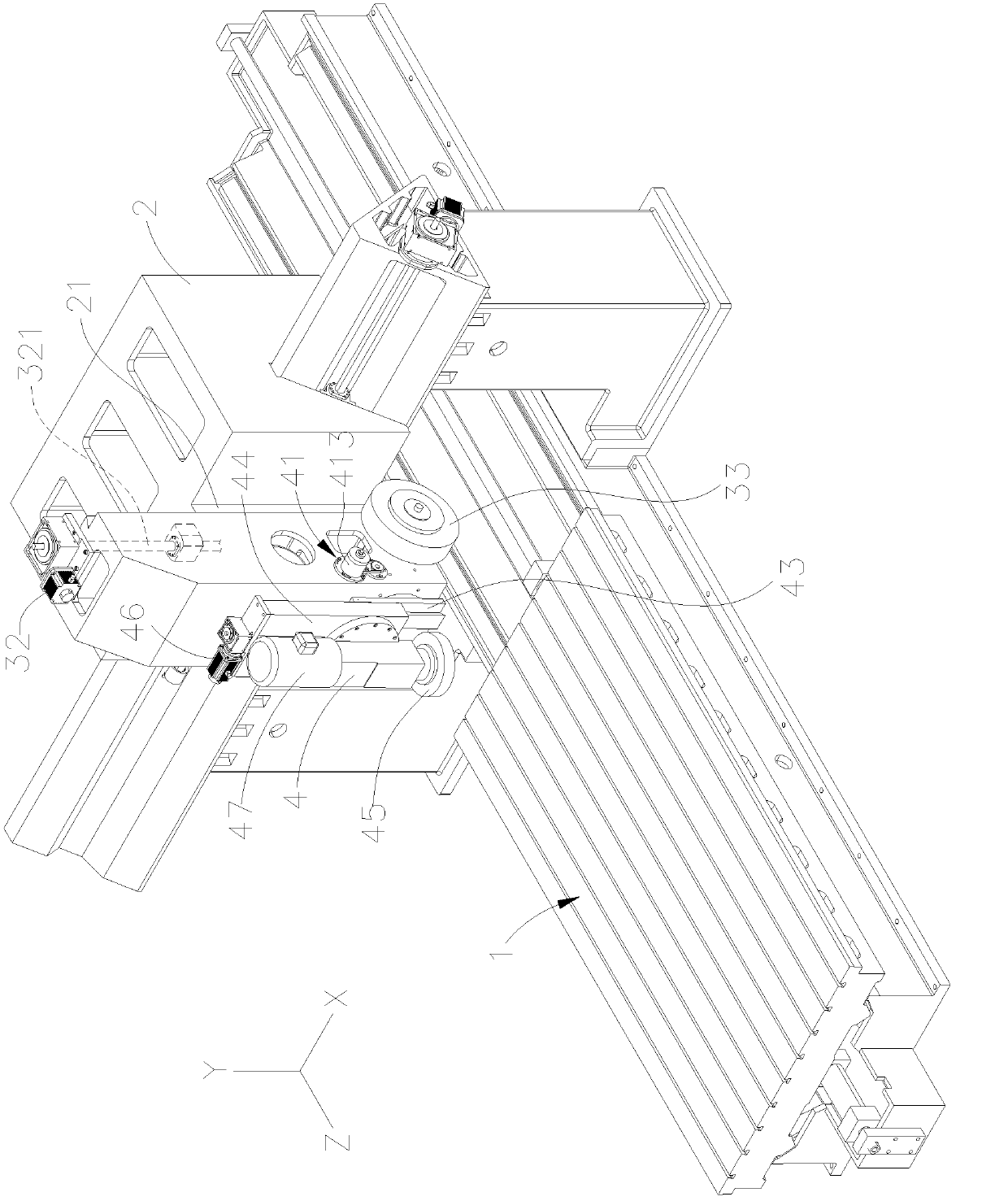

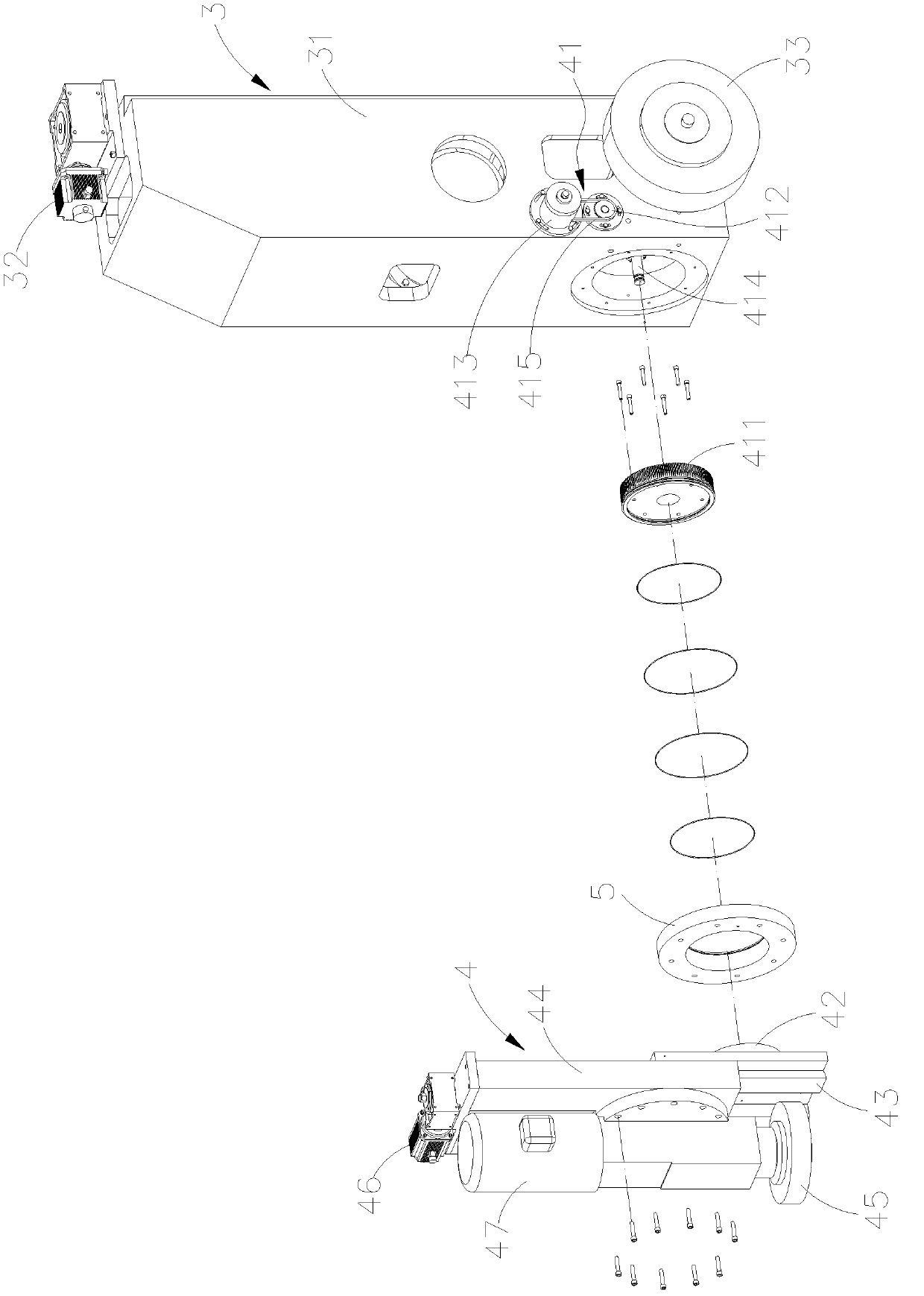

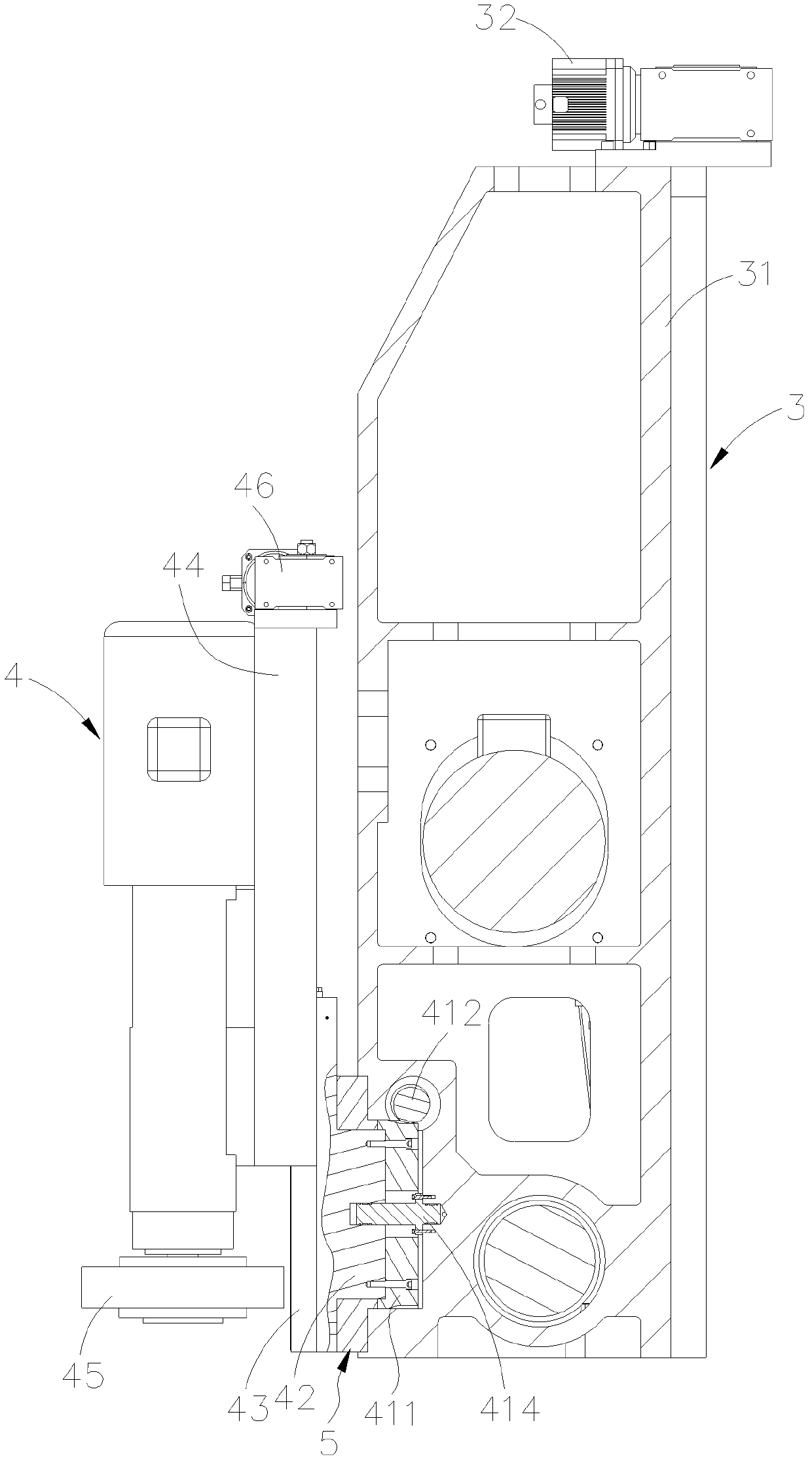

[0038] First please refer to Figure 1 to Figure 4 As shown, the embodiment of the present invention provides a grinding machine structure with a locatable and movable rotating vertical grinding head, which mainly consists of a machine body 1, a sliding seat 2, a first grinding head group 3 and a second grinding head Group 4 and so on are combined.

[0039] The structure of the body 1 is generally the same as that commonly used, and will not be described in detail here. The workpiece can be ground in the directions of X, Y, and Z axes on it.

[0040] The sliding seat 2 is slidably arranged on the X-axis direction of the machine body 1 , and has a sliding groove 21 formed on the Y-axis direction.

[0041] The first grinding head group 3 utilizes a housing 31 to be slidably arranged in the chute 21 of the slide seat 2, that is, a guide rail 311 is formed on the housing 31 (such as figure 1 , Figure 4 As shown), the guide rail 311 and the chute 21 are combined with each other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com