Flat seaming device for elastic belt

An elastic band and interlock seam technology, which is applied in sewing equipment, sewing machine components, textiles and papermaking, etc., can solve the problems of uneven stitching, cumbersome production steps, and low yield of finished products, so as to improve the yield of products , Improve production efficiency, the effect of uniform distance from the edge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

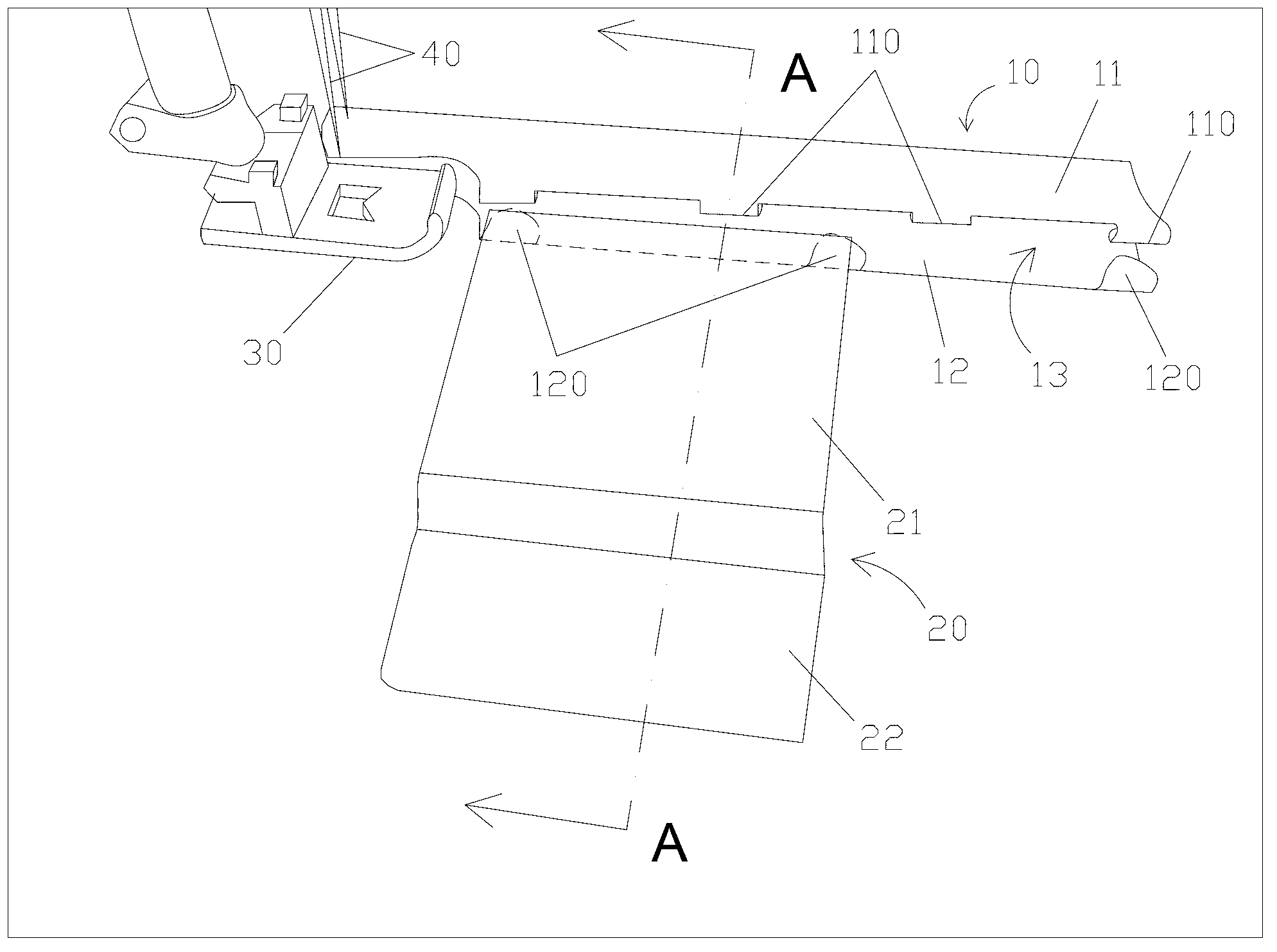

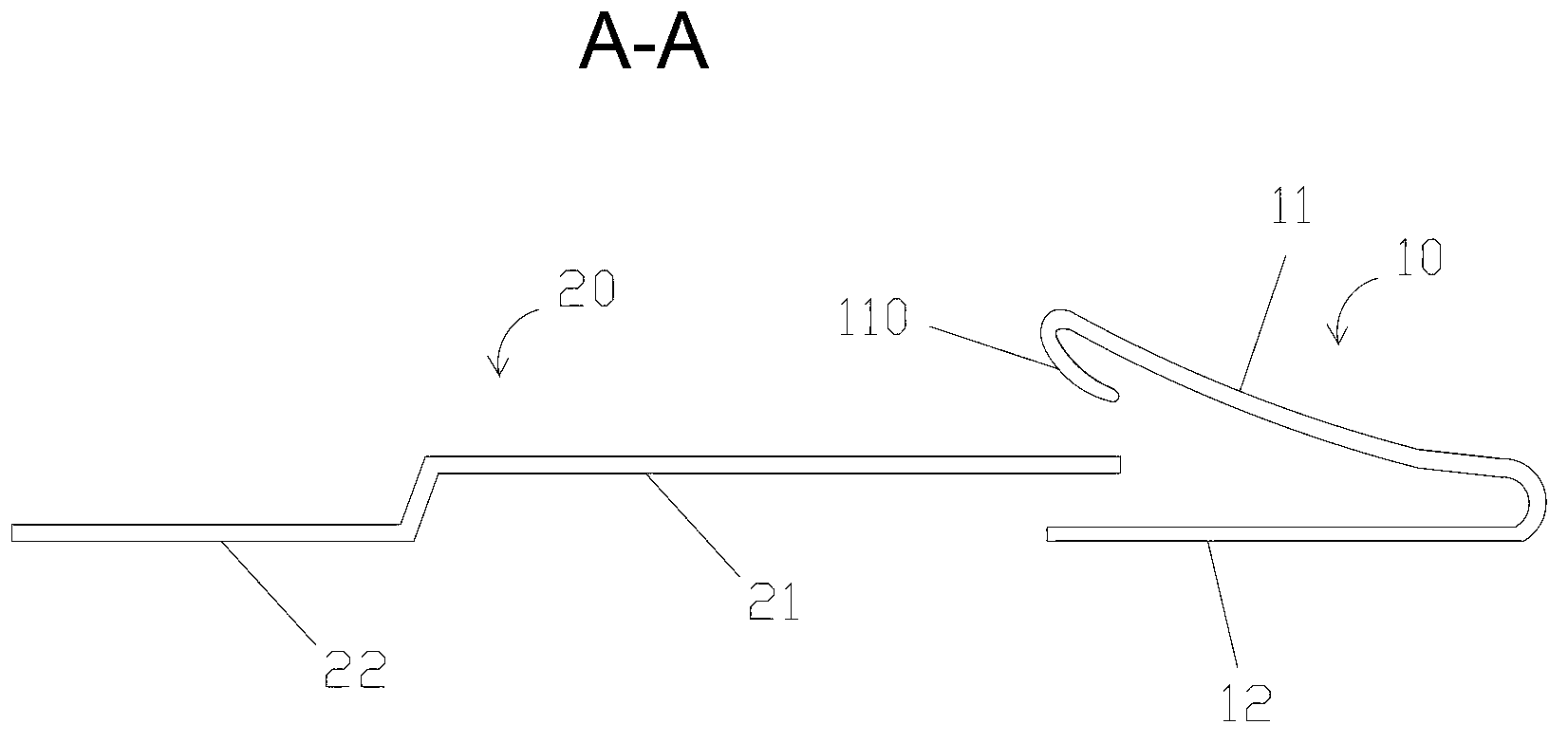

[0019] see figure 1 and figure 2 , the present invention provides an elastic band seaming device, which includes an opening clip 10 for transporting an elastic band with side openings along the length direction, and the opening clip 10 has an upper clip part 11 and a lower clip part 12 extending along the length direction, so The upper clamping part 11 and the lower clamping part 12 are connected at one end and the other end is gradually opened to form an opening 13. The upper clamping part 11 has an upper fold bent towards the inside of the opening at the edge of the opened end. The bent portion 110 , the lower clamping portion 12 has a lower bent portion 120 bent toward the inner side of the opening at one edge of the opened end. The included angle of the opening 13 gradually decreases along the length direction of the opening clip 10 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com