Automatic down coat pressure line stitching method

A technology for automatic cars and down jackets, applied in the field of garment processing, can solve problems such as uneven down filling, achieve the effects of improving work efficiency, reducing work intensity and power consumption of pressing lines, and good practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

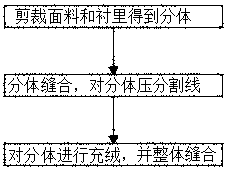

[0030] An automatic sewing method for down jacket crimping, such as figure 1 As shown, it mainly includes the following steps:

[0031] Step E1: cutting the fabric and lining to obtain a split, the split includes a front piece, a back piece, sleeves, a collar and a hat;

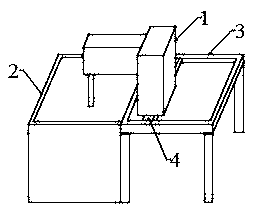

[0032] Step E2: separate sewing, place the aligned fabric and lining in the crimping device to press the dividing line, and reserve a fleece filling opening on each split part; place the split on the working platform 2, the work The laser device at the bottom of the platform 2 detects the size of the split structure, and the split line is pressed by the line-pressing device; the split is removed after the split line is pressed;

[0033] Step E3: filling the split body in step E2 with down filling, and then sewing up the opening filled with down; performing overall sewing on the split body after down filling to prepare a down jacket.

[0034] The present invention adopts line crimping device to carry out cri...

Embodiment 2

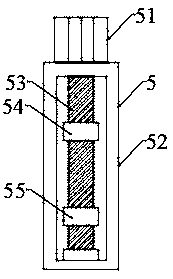

[0037] This embodiment is further optimized on the basis of embodiment 1, as image 3 As shown, the motion mechanism also includes a Z-axis motion device 5, and the horizontal motion frame moves up and down along the Z-axis direction on the Z-axis motion device 5; the Z-axis motion device 5 includes a screw rod 53, a servo motor 51 , mounting base 52; the mounting base 52 is fixed on the ground, the servo motor 51 is arranged on the upper end of the mounting base 52, and the servo motor 51 drives the screw rod 53 to rotate; the screw rod 53 is arranged in the mounting base 52, and The bottom of the screw rod 53 is rotatably connected to the mounting base 52 ; the horizontal movement frame is connected to the screw rod 53 through the first slider 54 .

[0038] During the use of the present invention, the split body is placed on the working platform 2, the laser device at the bottom of the working platform 2 detects the size of the split body, and the printing coordinates of the...

Embodiment 3

[0041] This embodiment is further optimized on the basis of Embodiment 2. The Z-axis motion device 5 is symmetrically arranged on both sides of the printing platform; the two ends of the horizontal motion frame are respectively connected to the screw rod 53 through the first slider 54 ; Also include a pressing plate 6, the two ends of the pressing plate 6 are respectively connected to the screw 53 through the second slider 55, and the second slider 55 is located at the bottom of the first slider 54; as Figure 4 As shown, the press plate 6 is provided with several suture slots 61 arranged equidistantly, and the crimping printing device 1 passes through the suture slots 61 to press the split line downward; on the press plate 6 The distance between adjacent stitching slots 61 is the width of adjacent dividing lines on the split body.

[0042] During the use of the present invention, the height of the pressing plate 6 can be adjusted by the screw 53, and the split body is placed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com