An Active Rotating Dynamic Mixer Applicable to Thick Oil Mixed and Thin Production

A dynamic mixer, active technology, applied in the direction of production fluid, earthwork drilling, wellbore/well components, etc., can solve the problems of poor mixing effect of heavy oil and thin oil, high pressure drop of wellbore flowing medium, etc., and achieve structural The effect of simplicity, low cost and easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

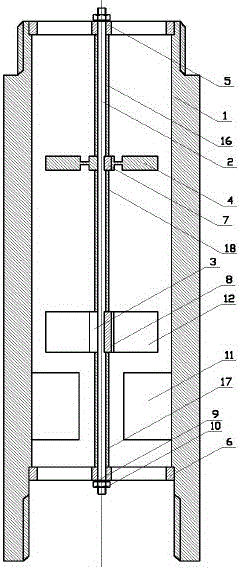

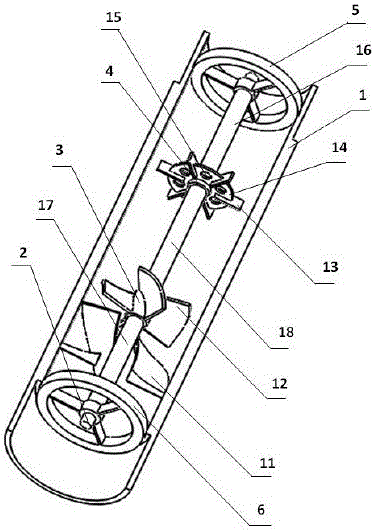

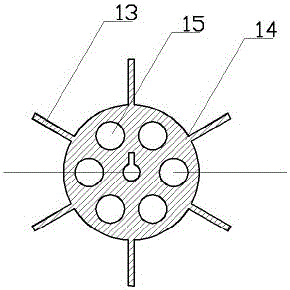

[0012] The present invention will be further described below in conjunction with drawings and embodiments.

[0013] Such as figure 1 , figure 2 , image 3 As shown, the present invention is an active rotating dynamic mixer suitable for heavy oil mixed with thin oil production, mainly composed of a cylinder body 1, a central shaft 2, a power impeller 3, a stirring impeller 4, an upper bearing 5, a lower bearing 6, and a flat key 7 , flat key 8, guide vane 11, power blade 12, stirring blade 13, disc 14, flow hole 15, limit sleeve 16, limit sleeve 17, limit sleeve 18, the upper end of the cylinder 1 passes through The external thread is connected with the tubing, the lower end of the barrel 1 is connected with the tubing or downhole tool through the internal thread, the upper and lower ends of the barrel 1 are provided with internal threads, the upper end of the barrel 1 is connected with the upper bearing 5 through the inner thread, the barrel 1. The lower end is connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com