Spherical display screen and manufacturing method thereof

A manufacturing method and a technology of a display screen, which are applied in the field of display screens, can solve problems such as picture distortion, composition of an approximate spherical surface, and pixel structure size limitation, and achieve undistorted picture display, improved display effect, and good display effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

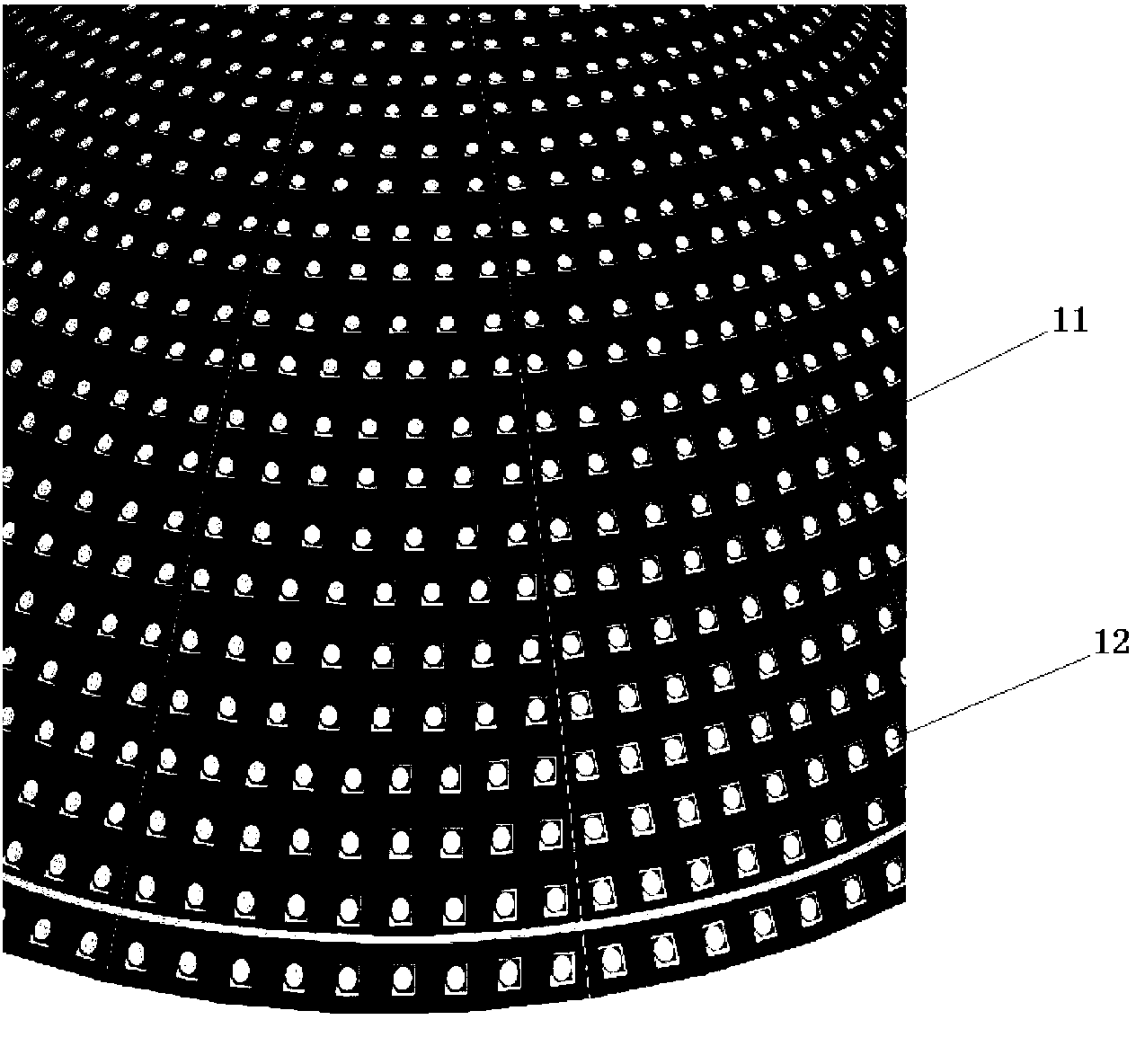

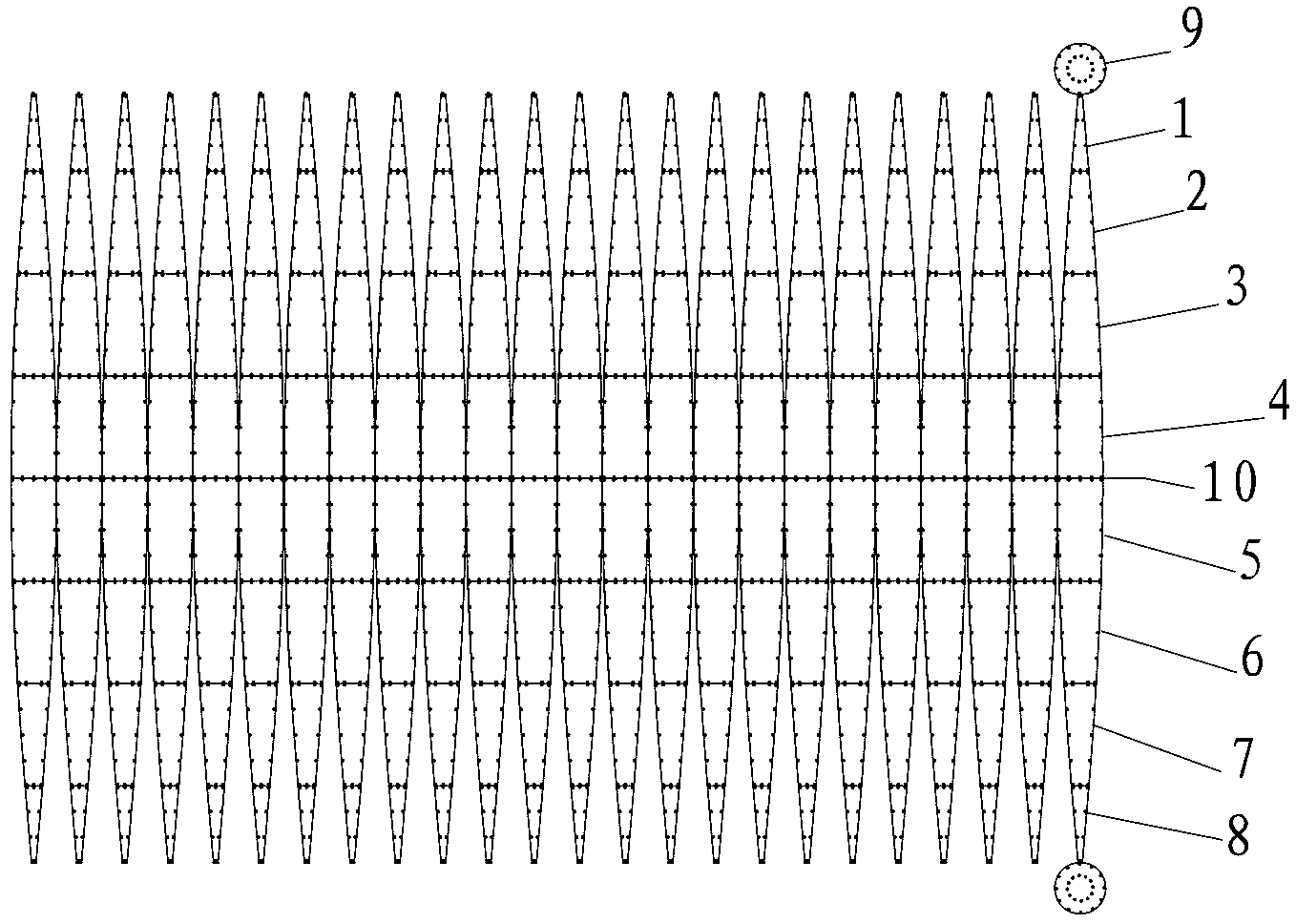

[0024] see figure 1 as well as figure 2 , a spherical display in this embodiment, including a spherical surface 11 and light-emitting pixel points 12, the spherical coordinates of the light-emitting pixel points 12 are distributed on the spherical surface 11, and the distribution of the light-emitting pixel points 12 is such that the light-emitting pixel points 12 are distributed along the curved surface On the spherical surface, it is completely distributed according to the spherical surface, so that the display screen of the spherical display screen of the present invention not only has high resolution, but also does not distort the screen, and the overall display effect is greatly improved.

[0025] In this embodiment, the luminous pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com