Austenitic stainless steel submerged-arc welding wire with excellent high-temperature strength

A technology of austenitic stainless steel and high-temperature strength, which is applied in the direction of welding medium, welding equipment, welding/cutting medium/material, etc., and can solve problems such as insufficient mechanical properties of welds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below through embodiment.

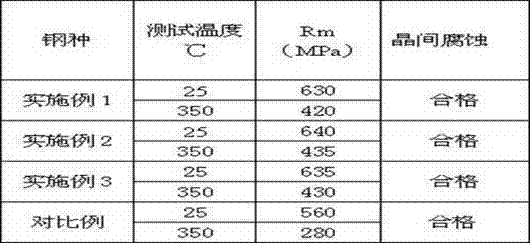

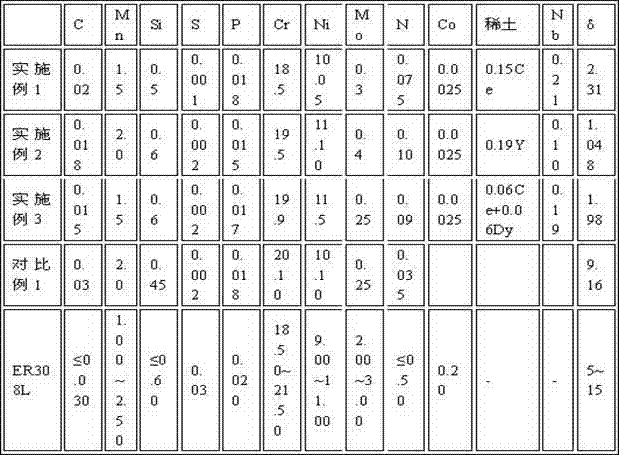

[0039] The chemical composition of the welding wire of the present invention and the tensile strength of the welded joint are respectively listed in Table 1 and Table 2. In order to compare the excellence of the welding wire of the present invention, a comparative test is also performed on the conventionally used ER308L welding wire and listed in the table. The ferrite δ content in Table 2 is calculated using the following formula: Cont(δ)=3*(Cr+Mo)+4.5*Si-2.8*Ni-1.4*Mn-84*(C+N)-19.8. It can be seen from Table 2 that, compared with common comparative example 1, the austenitic stainless steel welding consumable welding joint of the present invention has excellent high-temperature strength, and can be used for welding or repairing equipment in a nuclear island reactor at a temperature of 350°C .

[0040] The four kinds of welding wires used in the test were prepared by the same production proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com