Guidance mechanism for optical disc mold positioning

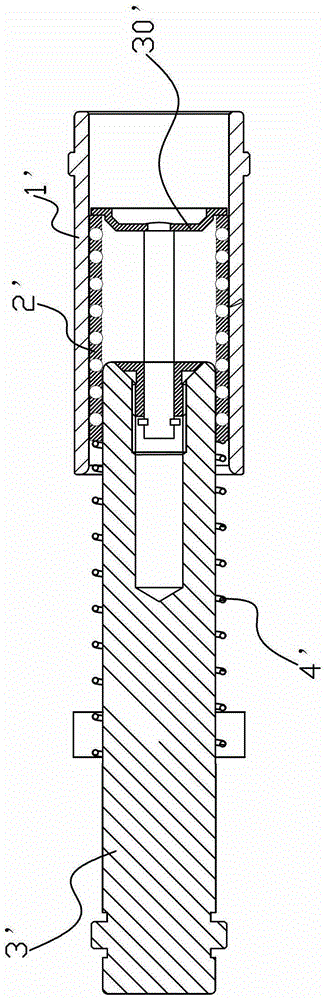

A technology of guiding mechanism and mold, applied in the field of guiding mechanism, can solve problems such as pressing mold, hidden danger, failure and aging of pressure spring 4', and achieve the effect of solving hidden safety hazard and production safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

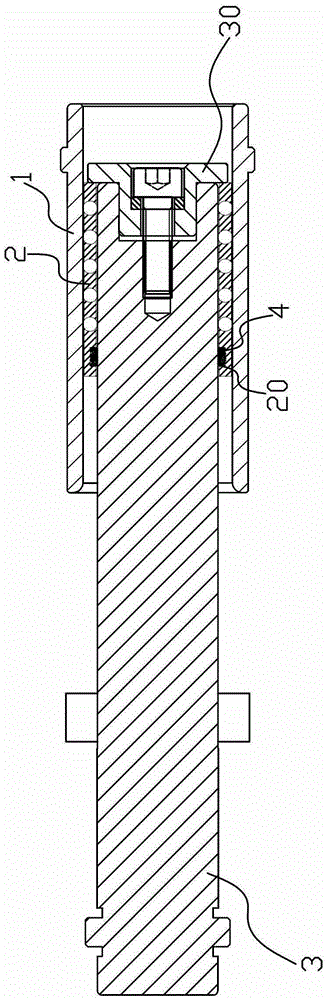

[0014] refer to figure 2 , the guide mechanism used for the positioning of the optical disc mold, including a guide sleeve 1 fixedly installed on the fixed mold, the inside of the guide sleeve 1 is movably embedded with a ball sleeve 2, and the inside of the ball sleeve 2 is movable. The guide post 3 on the movable mold, the inside of the ball sleeve 2 is fixedly provided with a wear-resistant ring 4 sleeved on the guide post 3, and the gap between the wear-resistant ring 4 and the guide post 3 is The ball sleeve 2 is fixed on the guide post 3, so the guide post 3 drives the ball sleeve 2 to move toward or away from the fixed mold in the guide sleeve 1. When the guide post 3 stops, the ball sleeve 2 It will also stop immediately and will not continue to move forward. Therefore, when the guide post 3 stops, the ball sleeve 2 can be prevented from being exposed from the guide sleeve 1 by continuing to move forward along the guide post 3 due to inertia, because The ball sleeve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com