An asymmetric rail positioning and clamping device

A positioning and clamping, asymmetrical technology, applied in the direction of auxiliary equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as trouble, insufficient opening, time-consuming and laborious turning of welding equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

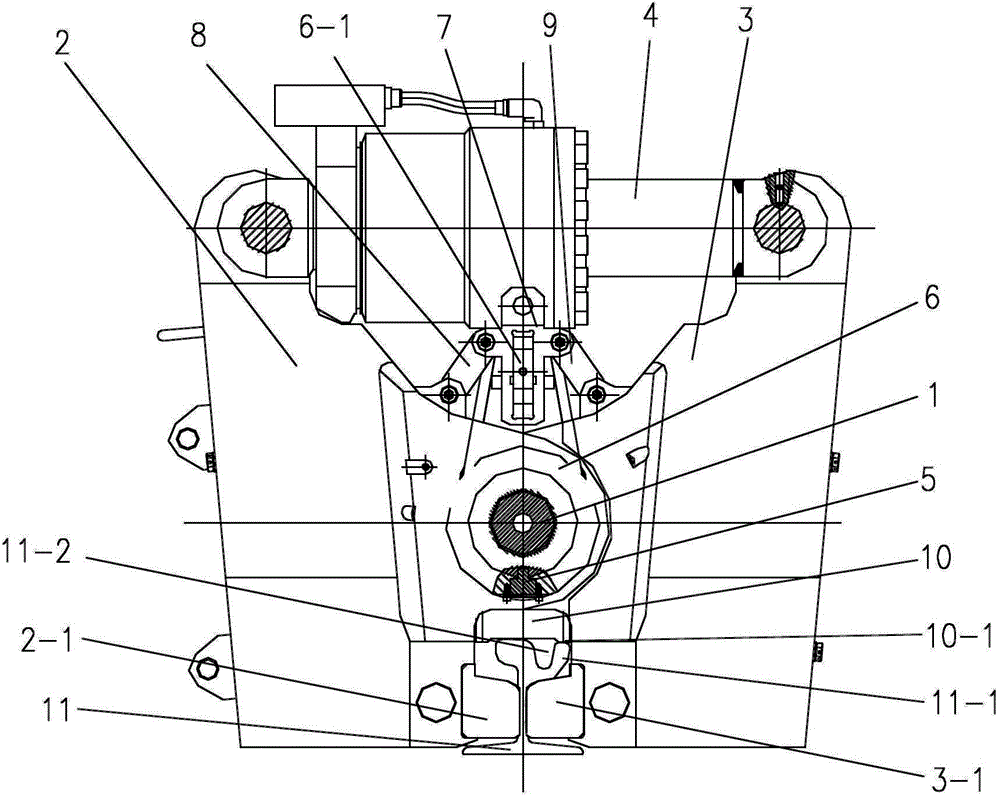

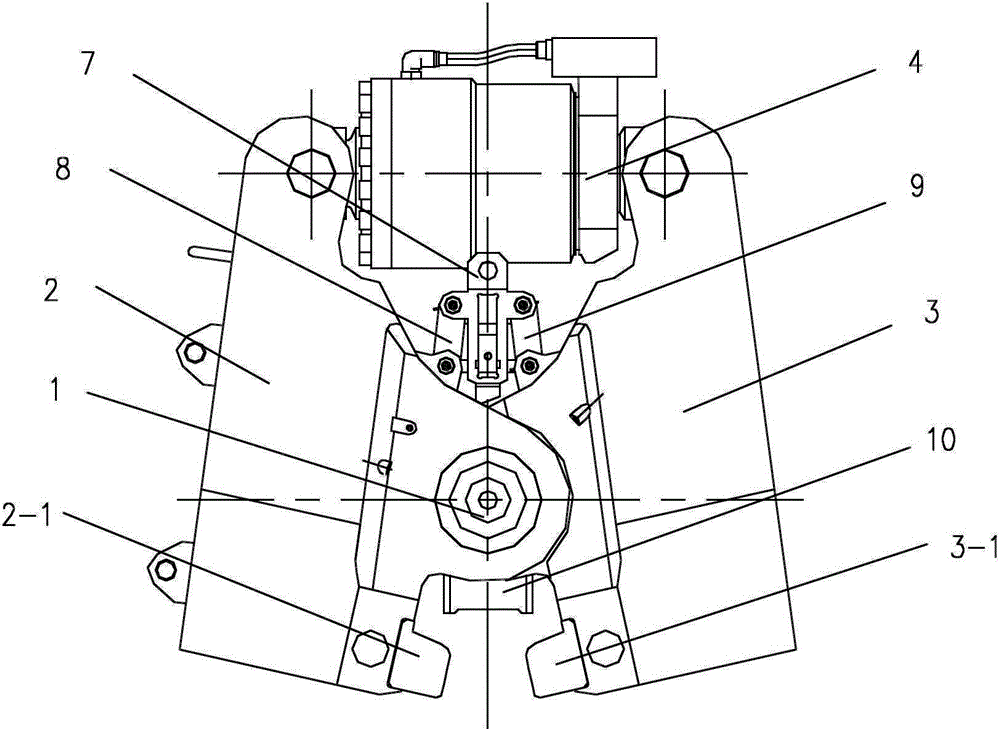

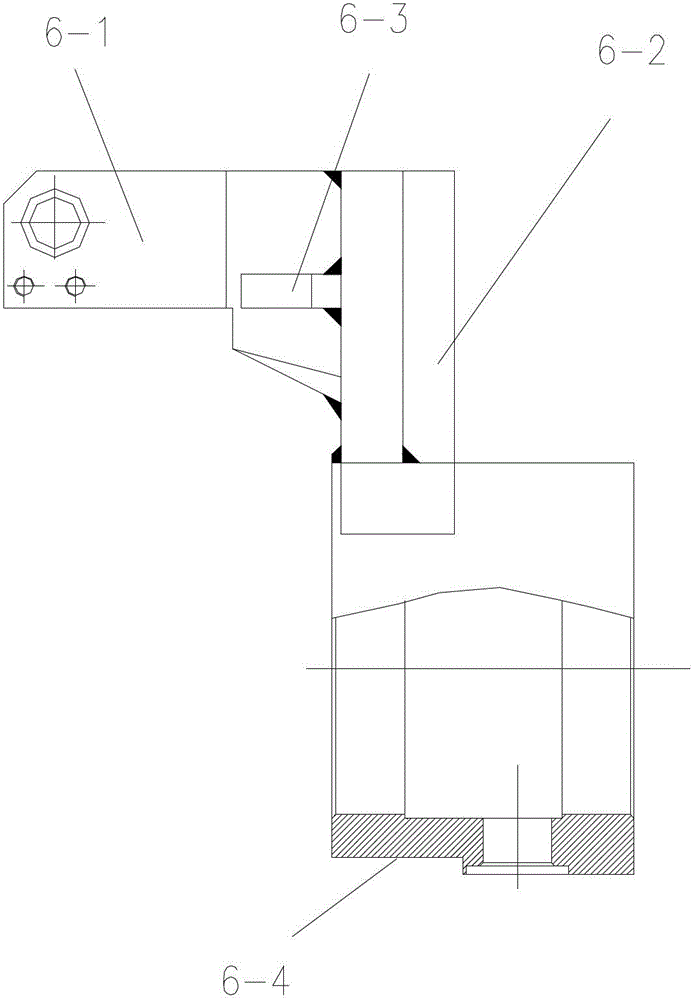

[0023] The basic structure of the asymmetric rail positioning and clamping device in this embodiment is as follows: figure 1 As shown, it includes left and right clamp boxes 2, 3 whose middle parts are hinged to each other through a fixed central hinge shaft 1. The lower parts of the left and right clamping boxes 2 and 3 respectively have relatively convex symmetrical left and right jaws 2-1 and 3-1. The upper ends of the left and right clamp boxes 2 and 3 are respectively hinged with the two ends of the horizontally telescopic clamping oil cylinder 4 . The central hinge shaft 1 is fitted with the hoisting shaft sleeve 6 (the key 5 is mounted on the lower other end of the shaft sleeve main body of the hoisting shaft sleeve 6) which is constrained in the circumferential direction by the key 5 and extends upwards out of the vertical guide block 6-1. The hoisting axle sleeve 6 is contained in the central hinge shaft 1 and is positioned between the left and right clamp casings. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com