Marine impact cut-off safety coupling

A safety coupling, marine technology, applied in couplings, slip couplings, mechanical equipment, etc., can solve the problems of power limitation, inability to use large ships, difficult to consider the rapid recovery of shafting functions, etc., to reduce Impact load, simple structure, easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings, but they do not constitute a limitation to the present invention, and are only examples. At the same time, the advantages of the present invention will become clearer and easier to understand through the description.

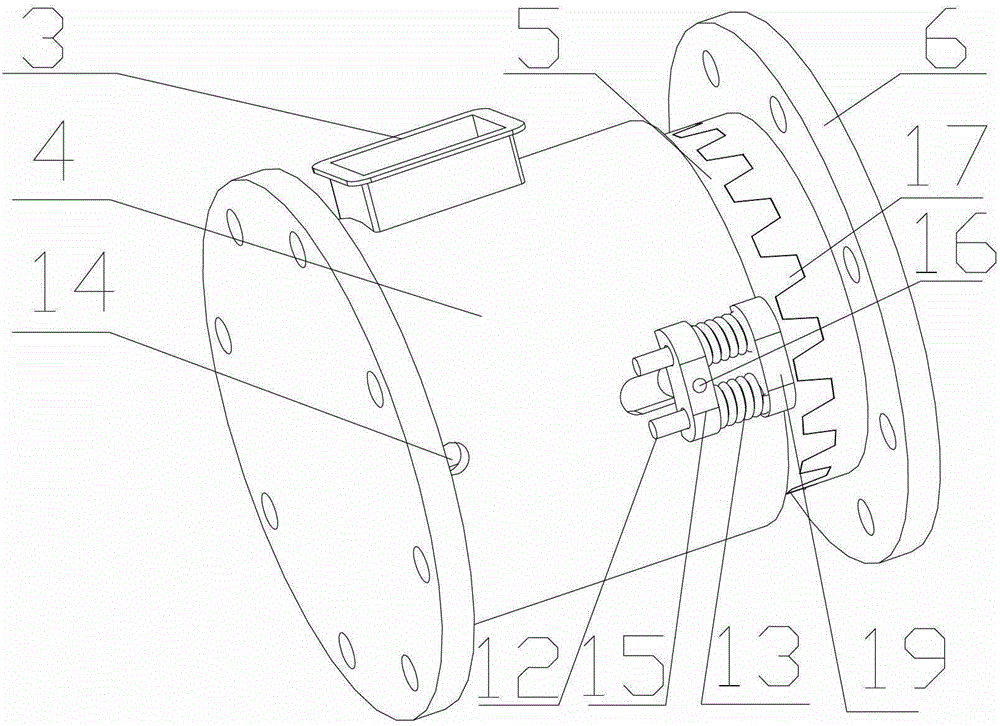

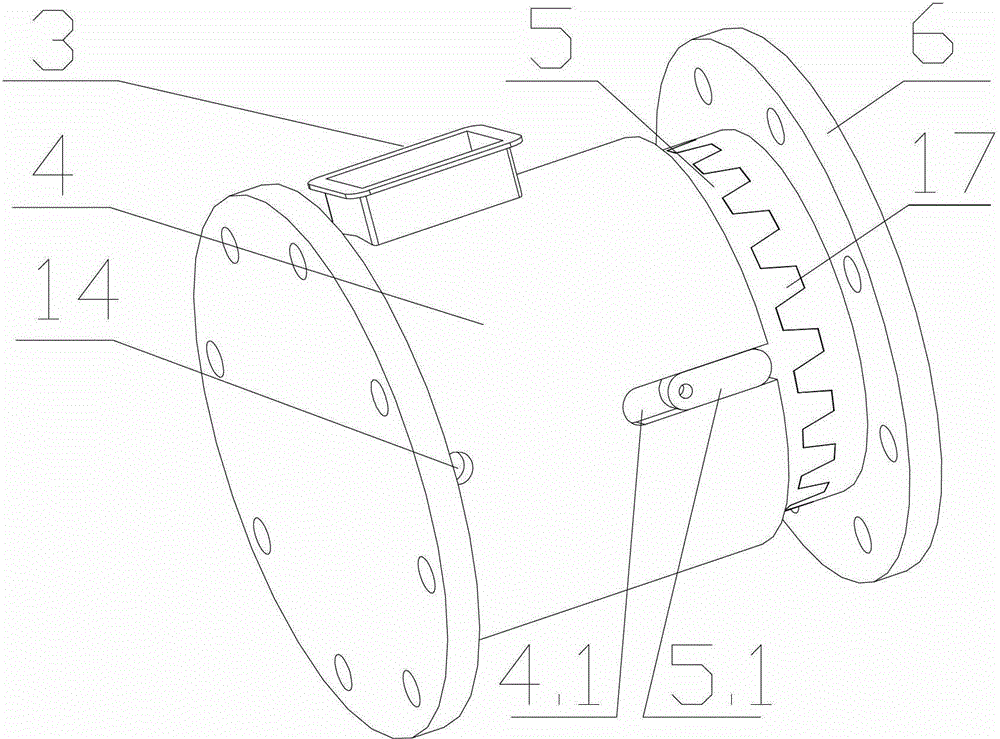

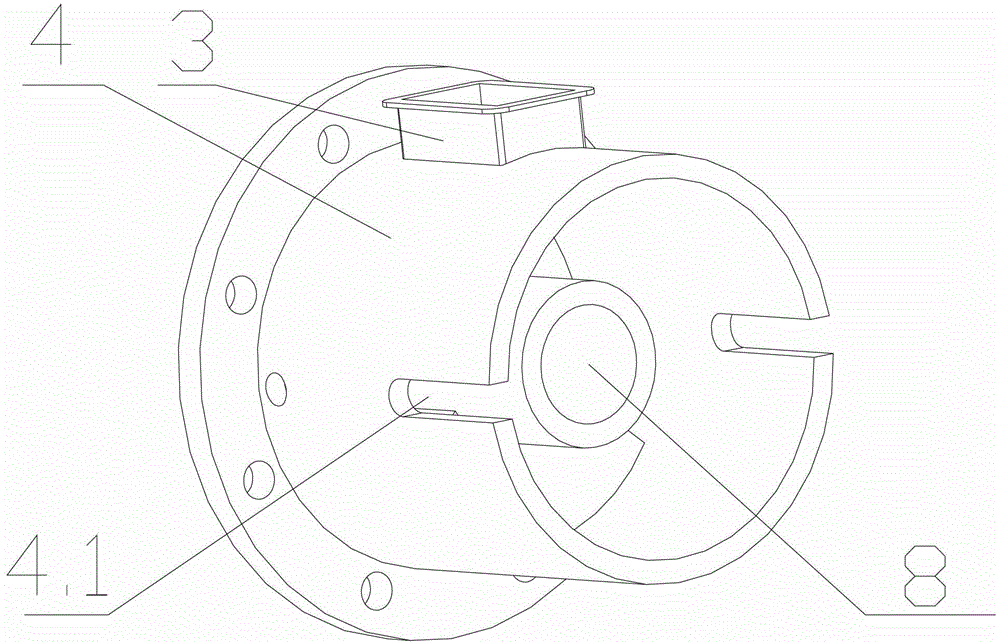

[0029] Referring to the accompanying drawings, we can see that: Figure 1 to Figure 6 As shown, the marine impact cut-off safety coupling includes the connecting flange 6 at the main engine end and the connecting flange 4 at the shafting end. A piston-type intermediate body 5 with axial sliding fit in the flange 4; an oil chamber 8 is provided in the shafting end connecting flange 4 or the main engine end connecting flange 6, and a piston 5.2 is arranged in the oil chamber 8. The piston 5.2 is connected with the piston-type intermediate body 5, and the oil chamber 8 is provided with an oil inlet 14 and an oil discharge port 7 contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com