Heat re-conduction glass tube solar assembly

A heat-conducting glass, solar energy technology, applied in the directions of solar thermal energy, solar thermal power generation, solar thermal collectors, etc., can solve the problems of insufficient effect, small solar energy, and solar energy cannot be reused, and can solve the problem of inability to keep warm Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

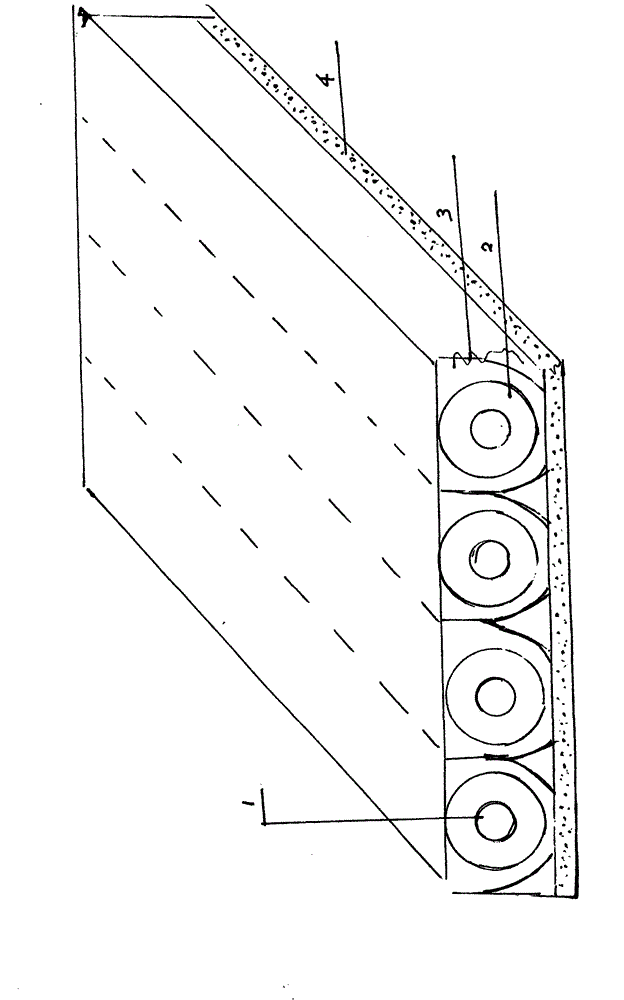

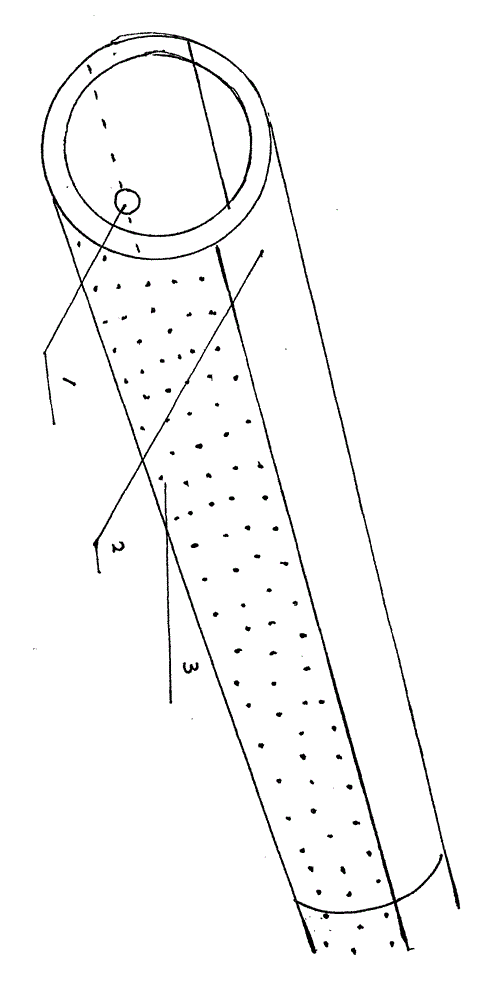

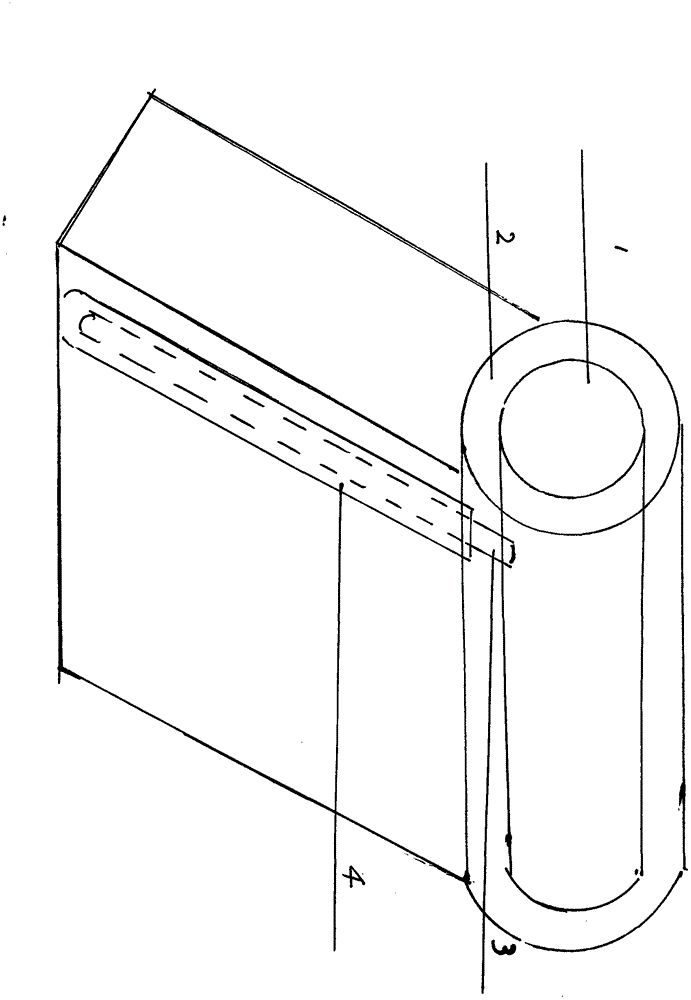

[0017] see figure 1 A schematic diagram of a reheat-conducting glass tube solar energy assembly is shown, and an example of a solar heat-conducting tube conducting heat again is given. There is a rear wall heat-insulating and heat-conducting plate as a support, and aluminum alloy and glass are used as a skeleton support to form a re-conducting heat with solar energy. A reheat-conducting glass tube solar assembly skeleton in which the glass tubes are matched. figure 1 1 in is the solar heat pipe, figure 1 2 in is the solar heat conduction glass tube again, figure 1 3 is the aluminum alloy glass skeleton, which is an arc-shaped heat conductor, the arc surface is pasted by a heat conduction plate, and the gap is filled with heat conduction materials. figure 1 The 4th is that the surface of the back wall thermal insulation and heat conduction plate is fully pasted by heat conduction material, and combined into a kind of reheat conduction glass tube solar energy assembly.

[001...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com