Yarn lifting mechanism for waste yarn collection

A technology of waste yarn and driving mechanism, which is applied to auxiliary equipment for weaving, textiles, textiles, and papermaking. It can solve the problems of waste thread ends floating to other places to pollute workshops, waste thread ends that cannot be sucked away, and difficult to collect, so as to increase energy consumption. The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

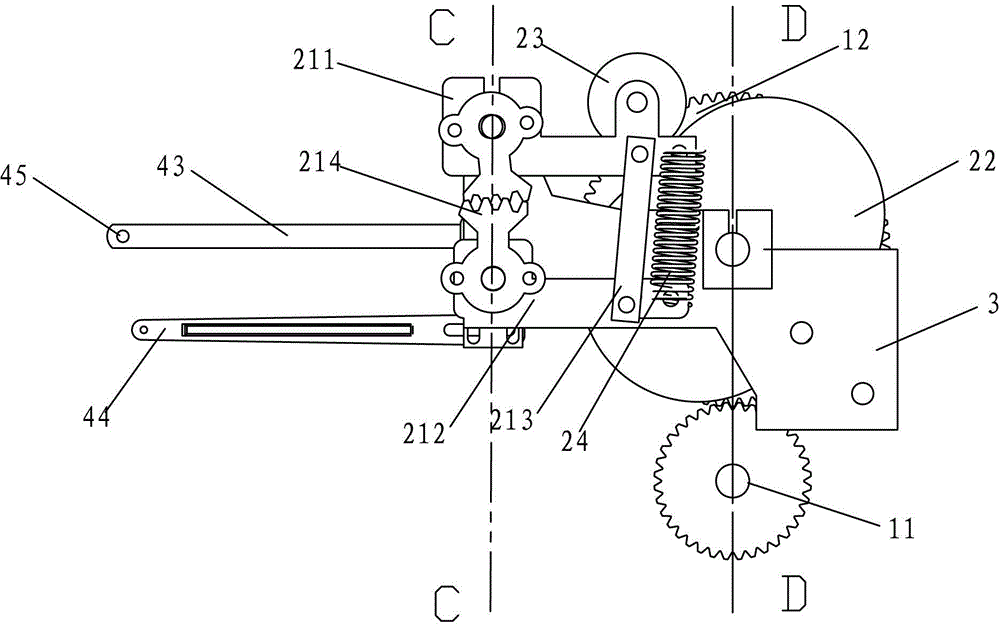

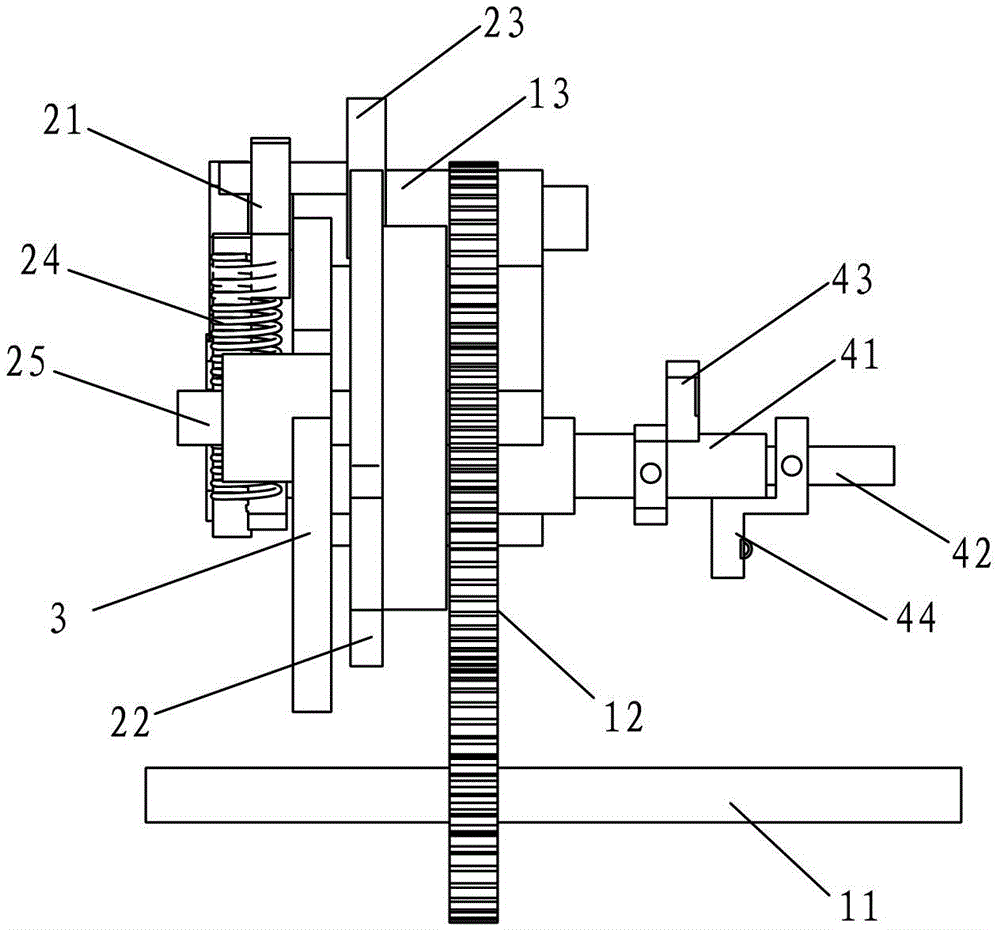

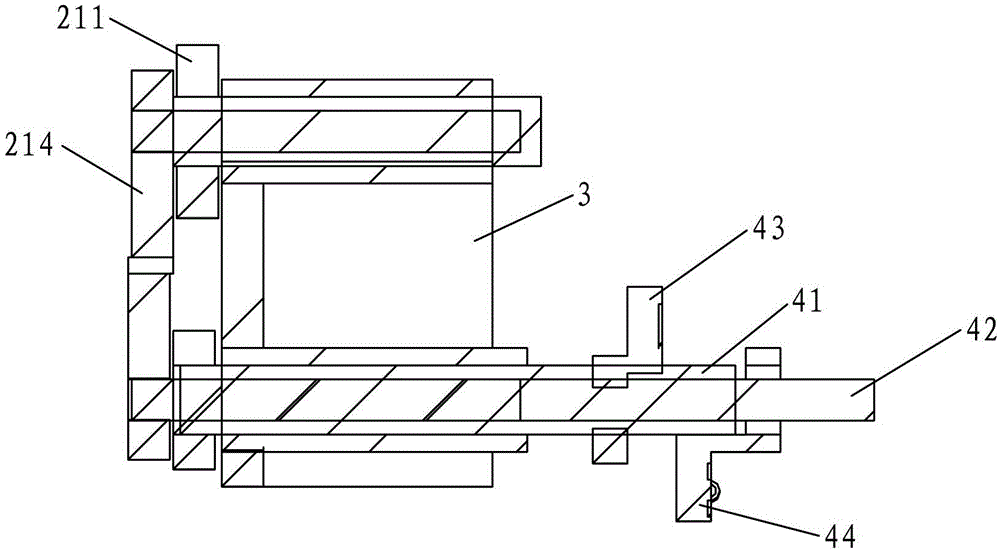

[0022] Such as Figure 1-4 As shown, the present invention discloses a yarn lifting mechanism for waste yarn collection, which includes a driving mechanism 1, a transmission mechanism 2, a mounting plate 3 and a nip 4, and the transmission mechanism 2 includes an eccentric rotatably mounted on the mounting plate 3. Wheel 22, the pinch wheel 23 that is arranged on the eccentric wheel 22 edges, the return spring 24 that is used to reset the pinch wheel 23, the link mechanism 21 that is connected with the pinch wheel 23, the jaw 4 includes being fixedly arranged on the upper and lower pinch bar shafts ( 41,42) on the upper and lower clamping rods (43,44), the ends of the upper and lower clamping rods (43,44) are provided with through holes 45, and the rotation of the upper and lower clamping rod shafts (41,42) is arranged on the installation plate 3.

[0023] The link mechanism 21 includes a first transmission rod 211, a second transmission rod 212, a connecting rod 213, and a b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com