Automatic rubber coating machine of motor end cover

A technology of motor end cover and gluing machine, which is applied in the direction of coating, liquid coating device on the surface, etc. It can solve the problems of low product pass rate, low gluing precision, glue waste and other problems, and achieve a one-time pass rate High efficiency, wide application range and less waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

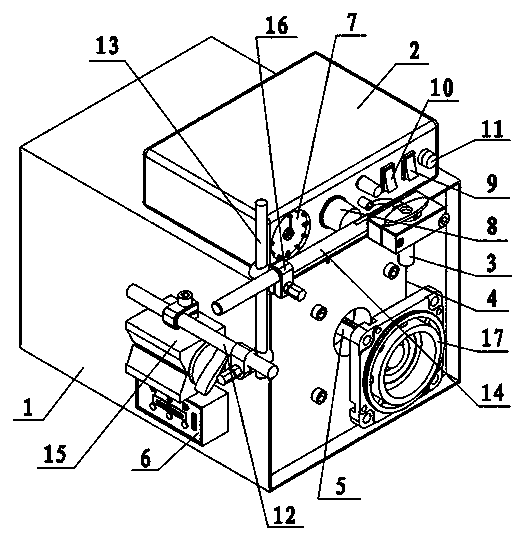

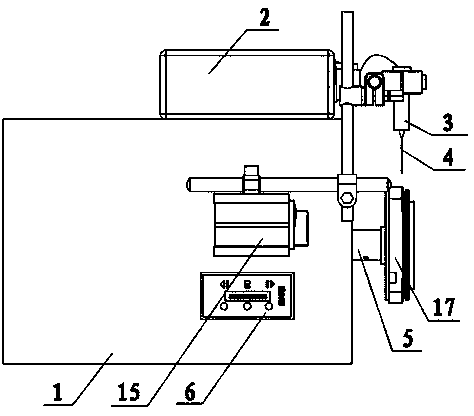

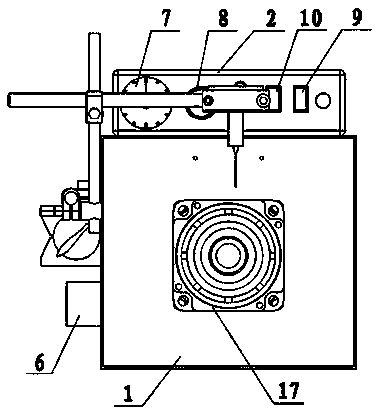

[0013] Below in conjunction with accompanying drawing, the present invention will be further described:

[0014] Automatic gluing machine for motor end cover, including chassis 1, glue dispensing controller 2, glue outlet barrel 3, adjustment bracket and stepping motor, the stepping motor is set in the chassis 1, and the output shaft of the stepping motor is set with a connector 5 , the motor end cap 17 is set on the connector 5, which can be connected to different motor end caps; a glue-coating position controller 6 is set on the chassis 1, and the glue-coating position controller 6 is connected with the stepping motor, which can precisely control the motor The end cover is rotated to adapt to glue application in different ways and positions; the glue dispensing controller 2 is set on the top of the chassis 1, and the glue dispensing controller 2 is provided with an air inlet and an air outlet. The controller 2 is also provided with a pressure display 7, a pressure regulating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com