Automatic operation table facet adjusting device

An automatic adjustment, table top technology, used in workbenches, manufacturing tools, etc., can solve the problems of difficult operation, large volume and weight of workpieces, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

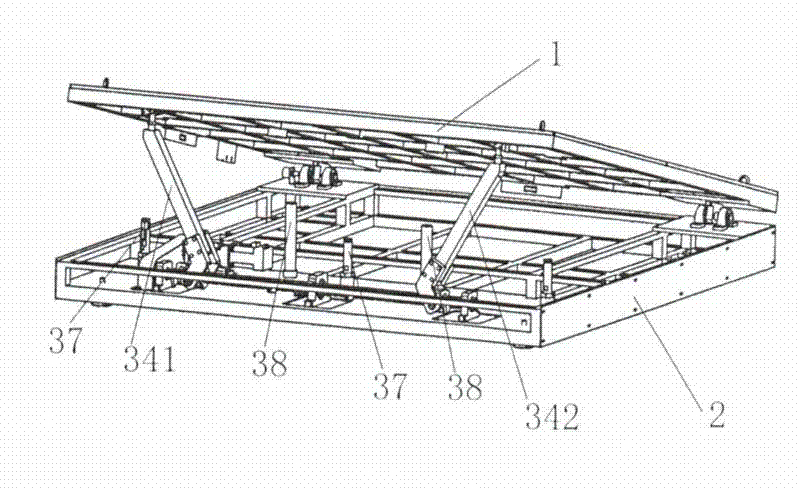

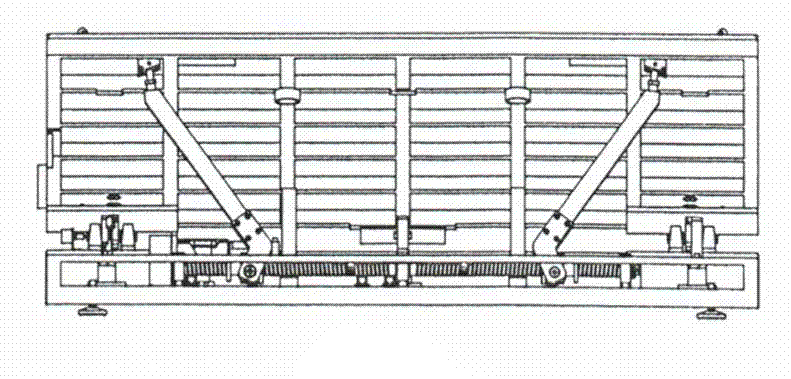

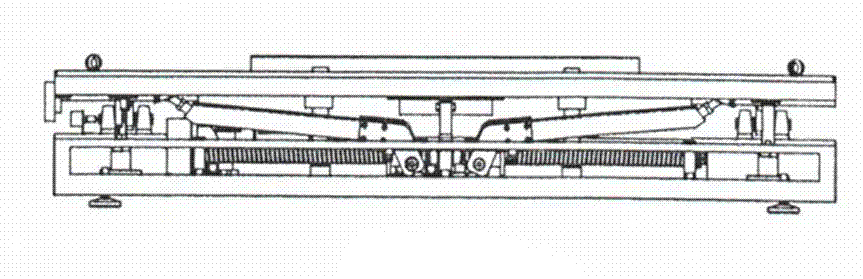

[0031] combine figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Image 6 , as described in detail below:

[0032] An automatic adjustment device for an operating table, comprising an operating table 1 and a base 2, one side of the operating table 1 and the base 2 are rotatably connected by two side-by-side rotating mechanisms 39, and the rotating mechanism includes two bearing seats 3911 and 3912 at both ends respectively. The rotating shaft 392 fixed on the base 2 and the connecting seat 393 that is sheathed in the middle of the rotating shaft 392, the connecting seat 393 is fixed on the operating table 1 at the same time, and the end of the rotating shaft 392 in one of the rotating mechanisms is also provided to facilitate the control of the The angle encoder 394 for rotating the inclination angle of the console surface 1, and a lifting mechanism is provided between the console surface 1 and the other side of the base 2. The two nuts 321, 322 on both sides a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com